Bio-based water-based coating as well as preparation method and application thereof

A water-based coating, bio-based technology, applied in the field of coatings, can solve the problems of inapplicable long-term antibacterial, easy to produce superbugs, and drug resistance, etc., achieve strong photooxidative catalytic antibacterial activity, improve photocatalytic oxidation activity, and enhance antibacterial performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

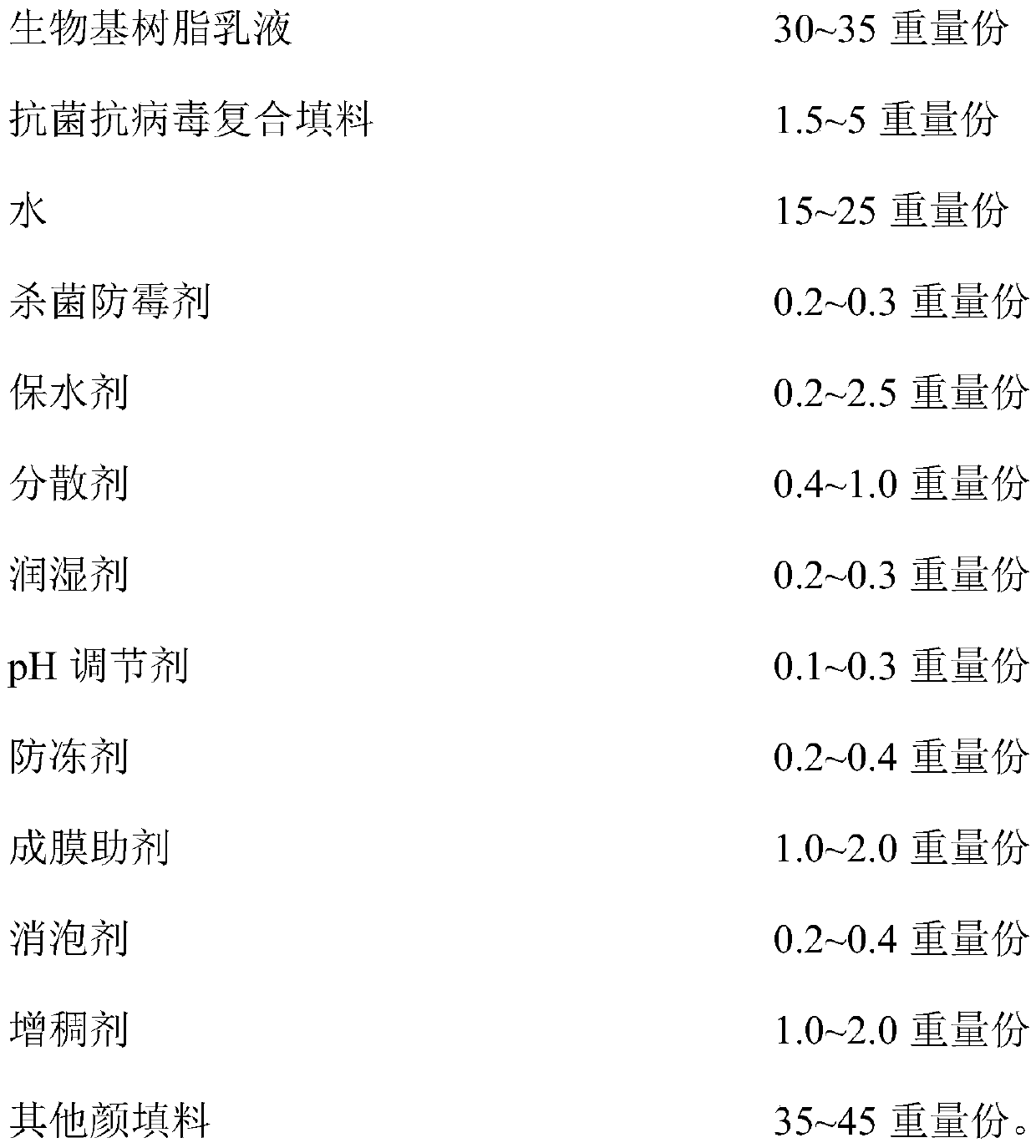

[0092] A bio-based water-based paint, the component formula of which is shown in Table 1, and the unit of each component in the formula is "parts by weight".

[0093] Table 1

[0094]

[0095]

[0096] In Table 1, the bio-based resin emulsion is DSM plant-based emulsion SP-8408 / 8409 with a C14 content of 30%; the dispersant is a mixture of Dow 1124 and 731A in a mass ratio of 3:2; the wetting agent is Clariant LFH ; pH adjuster is Solvay AN130; antifreeze is Solvay anti-freeze-thaw stabilizer FT100; sterilization and antifungal agent is MBS5050; It is a mixture of UH-450VF and ASE-60 in a mass ratio of 4:1; the water retention agent is cellulose ether; the titanium dioxide is rutile, DuPont R103.

[0097] The preparation method of the antibacterial and antiviral composite filler comprises the following steps:

[0098] (1) Mix 300g of kaolin (800 mesh), 100g of talc (800 mesh), 50g of sulfuric acid, 1.0g of sodium hexametaphosphate, 1.0g of polyacrylamide (average molec...

Embodiment 8

[0109] A bio-based water-based paint, the only difference from Example 1 is that the loading of nano-titanium dioxide in the antibacterial and anti-viral composite filler is 22%, the loading of nano-silver is 15%, and the loading of silicon oxide is 15%, The alumina loading was 6%.

[0110] The preparation method of the antibacterial and antiviral composite filler is as follows:

[0111] (1) 400g of kaolin, 50g of sulfuric acid, 1.0g of sodium hexametaphosphate, 1.0g of polyacrylamide and 1L of water were mixed and dispersed to obtain dispersion I; 32g of titanium tetrachloride, 4.5g of polyvinyl alcohol and 100mL of water were mixed uniform to obtain titanium tetrachloride hydrolyzate;

[0112] (2) the titanium tetrachloride hydrolysis that step (1) obtains is added dropwise in dispersion liquid I, reacts 5h, obtains the sample of loaded nano-silica;

[0113](3) mixing the sample obtained in step (2), 38 mL of silver nitrate solution with a concentration of 10% and 4.0 g of...

Embodiment 9

[0116] A bio-based water-based paint, the only difference from Example 1 is that the loading of nano-titanium dioxide in the antibacterial and anti-viral composite filler is 38%, the loading of nano-silver is 30%, and the loading of silicon oxide is 5%, The alumina loading was 14%.

[0117] The preparation method of the antibacterial and antiviral composite filler is as follows:

[0118] (1) 400g talc (800 meshes), 50g sulfuric acid, 1.0g sodium hexametaphosphate, 1.0g polyacrylamide (average molecular weight 8 million) and 1L water were mixed and uniformly dispersed to obtain dispersion liquid I; Titanium chloride, 6.8 g of polyvinyl alcohol and 100 mL of water are mixed uniformly to obtain a titanium tetrachloride hydrolyzate;

[0119] (2) the titanium tetrachloride hydrolysis that step (1) obtains is added dropwise in dispersion liquid I, reacts 5h, obtains the sample of loaded nano-silica;

[0120] (3) mixing the sample obtained in step (2), 50 mL of silver nitrate solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com