Method for preparing gallium arsenide polycrystal by recycling gallium arsenide waste

A waste recycling and gallium arsenide technology, applied in chemical instruments and methods, polycrystalline material growth, crystal growth, etc., can solve the problems of high impurities in single crystal tailings, waste of gallium arsenide, environmental pollution, etc., and achieve high productivity High, improved purity, reduced methanol demolding step effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

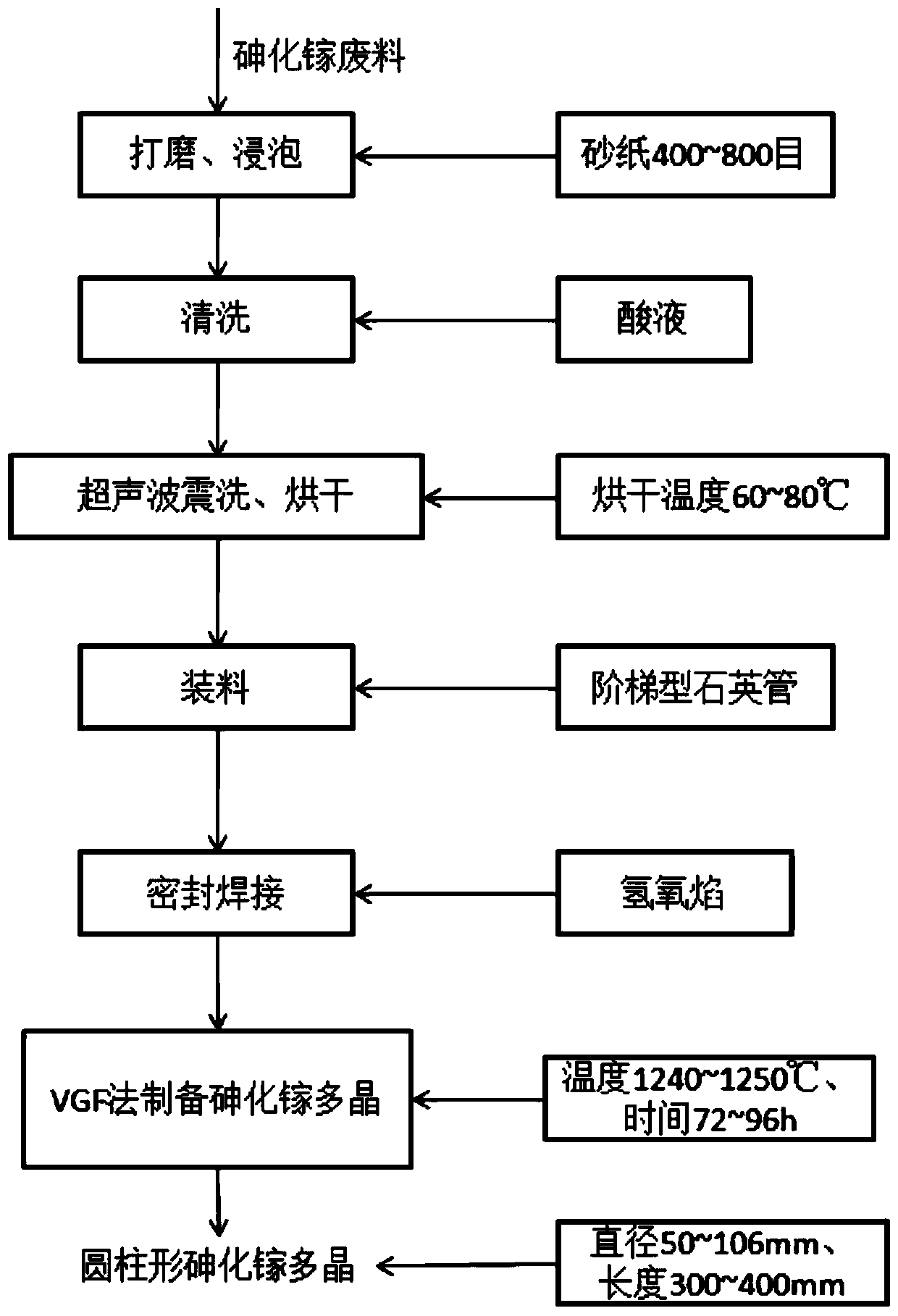

[0033] A method for preparing gallium arsenide polycrystalline by recycling gallium arsenide waste, said method comprising the following steps:

[0034] (1) Grind the gallium arsenide waste with 400-mesh sandpaper to remove the crucible residue and boron oxide pollution on the surface of the gallium arsenide waste, and then soak it in absolute ethanol to remove the boron oxide and oily substances that cannot be polished off, and soak The time is 30 minutes;

[0035] (2) Clean the gallium arsenide waste with a mixed solution of nitric acid, hydrofluoric acid and water to remove the silicon-free oxide layer of the gallium arsenide waste. The volume ratio of nitric acid, hydrofluoric acid and water is 9:1:1, wherein , the massfraction of nitric acid is 55.6%, and the massfraction of hydrofluoric acid is 4.5%;

[0036] (3) Ultrasonic shock washing, and then drying, the shock washing time is 1h, the drying time is 4h, and the drying temperature is 60°C;

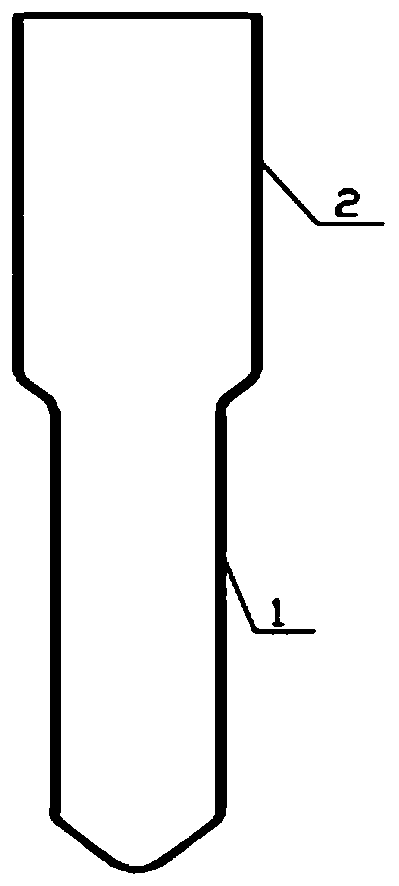

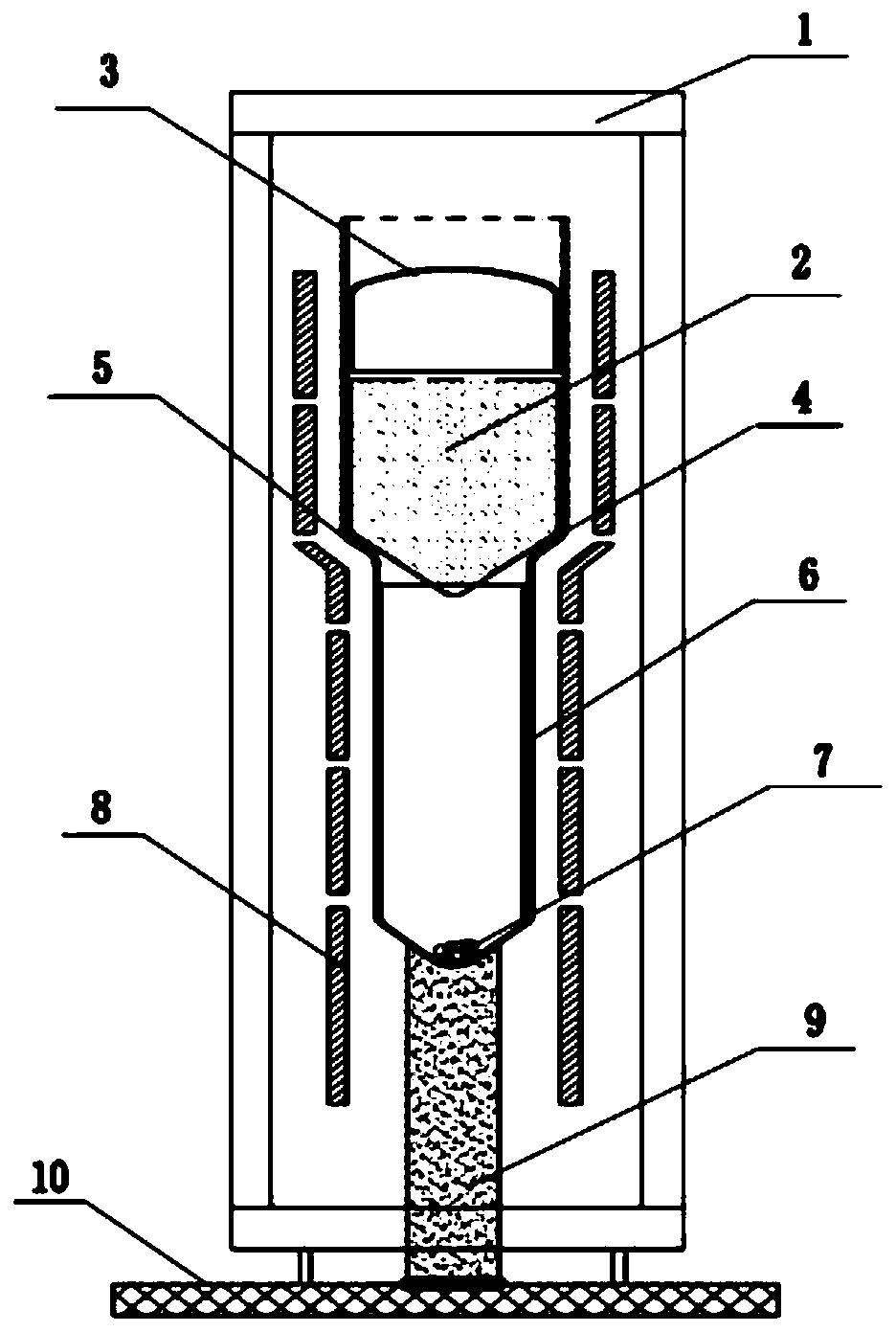

[0037] (4) Put 4Kg of dr...

Embodiment 2

[0041] A method for preparing gallium arsenide polycrystalline by recycling gallium arsenide waste, said method comprising the following steps:

[0042](1) Grind the gallium arsenide waste with 600-mesh sandpaper to remove the crucible residue, boron oxide and other pollution on the surface of the gallium arsenide waste, then soak it in absolute ethanol to remove the boron oxide and oily substances that cannot be polished off, and soak The time is 40 minutes;

[0043] (2) Clean the gallium arsenide waste with a mixed solution of concentrated hydrochloric acid and concentrated nitric acid to remove the silicon-free oxide layer of the gallium arsenide waste. The volume ratio of concentrated hydrochloric acid and concentrated nitric acid is 3:1, wherein the mass fraction of concentrated hydrochloric acid The mass fraction of concentrated nitric acid is 68%;

[0044] (3) Ultrasonic shock washing, and then drying, the shock washing time is 2 hours, the drying time is 3 hours, and ...

Embodiment 3

[0049] A method for preparing gallium arsenide polycrystalline by recycling gallium arsenide waste, said method comprising the following steps:

[0050] (1) Grind the gallium arsenide waste with 800 mesh sandpaper to remove the crucible residue, boron oxide and other pollution on the surface of the gallium arsenide waste, and then soak it in methanol to remove the boron oxide and oily substances that cannot be polished off. The soaking time is 60min;

[0051] (2) Clean the gallium arsenide waste with a mixed solution of nitric acid, hydrofluoric acid and water to remove the silicon-free oxide layer of the gallium arsenide waste. The volume ratio of nitric acid, hydrofluoric acid and water is 3:1:1, wherein , the massfraction of nitric acid is 40.8%, and the massfraction of hydrofluoric acid is 9.8%;

[0052] (3) Ultrasonic shock washing, and then drying, the shock washing time is 3 hours, the drying time is 2 hours, and the drying temperature is 80°C;

[0053] (4) Put 15Kg o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com