Ultrafast laser welding method applied to ceramics

An ultra-fast laser and welding method technology, applied in the field of ceramic material connection, can solve the problems that restrict the wide application of ceramic materials, the application is difficult to meet the requirements, and the thermal shock effect is large, so that the welding seam can be repeated, easy to automate, and thermal shock small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

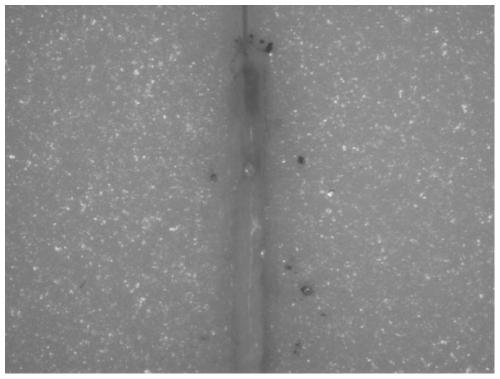

Embodiment 1

[0031] Turn on the ultrafast laser to weld the ceramic material, and the selected ceramic material is alumina ceramic. Use acetone, absolute ethanol, and deionized water in sequence to ultrasonically clean the surface of the alumina ceramic to be welded to remove surface impurities and oil, and dry it with a hair dryer. figure 1 On the movable working platform 7, by adjusting the pad iron 6, the pressure plate 5 is controlled to be parallel to the platform, and the bolt 4 is used to compress to realize the fixing of the ceramic 3 and the ceramic 8. Adjust laser parameters: laser power 36W, pulse width 300fs, repetition frequency 1MHz, adjust lens 3 so that the spot diameter is 0.1mm, scan speed 10mm / s, repeat 2 times for welding. figure 2 It is the effect picture of welding, and it can be seen that a vertical weld seam is formed.

[0032] Adopting the ultra-fast welding method of ceramics in the present invention can be applied to structural ceramics such as alumina ceramics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com