Bending-resistant high-flexibility drag chain cable and production method thereof

A technology of drag chain cable and production method, which is applied to bendable cables, insulated cables, bendable conductors, etc., can solve the problems of cracks on the surface of the protection outer layer, poor bending resistance, insufficient strength, etc., and is not easy to wrinkle. , Good wear resistance and good bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

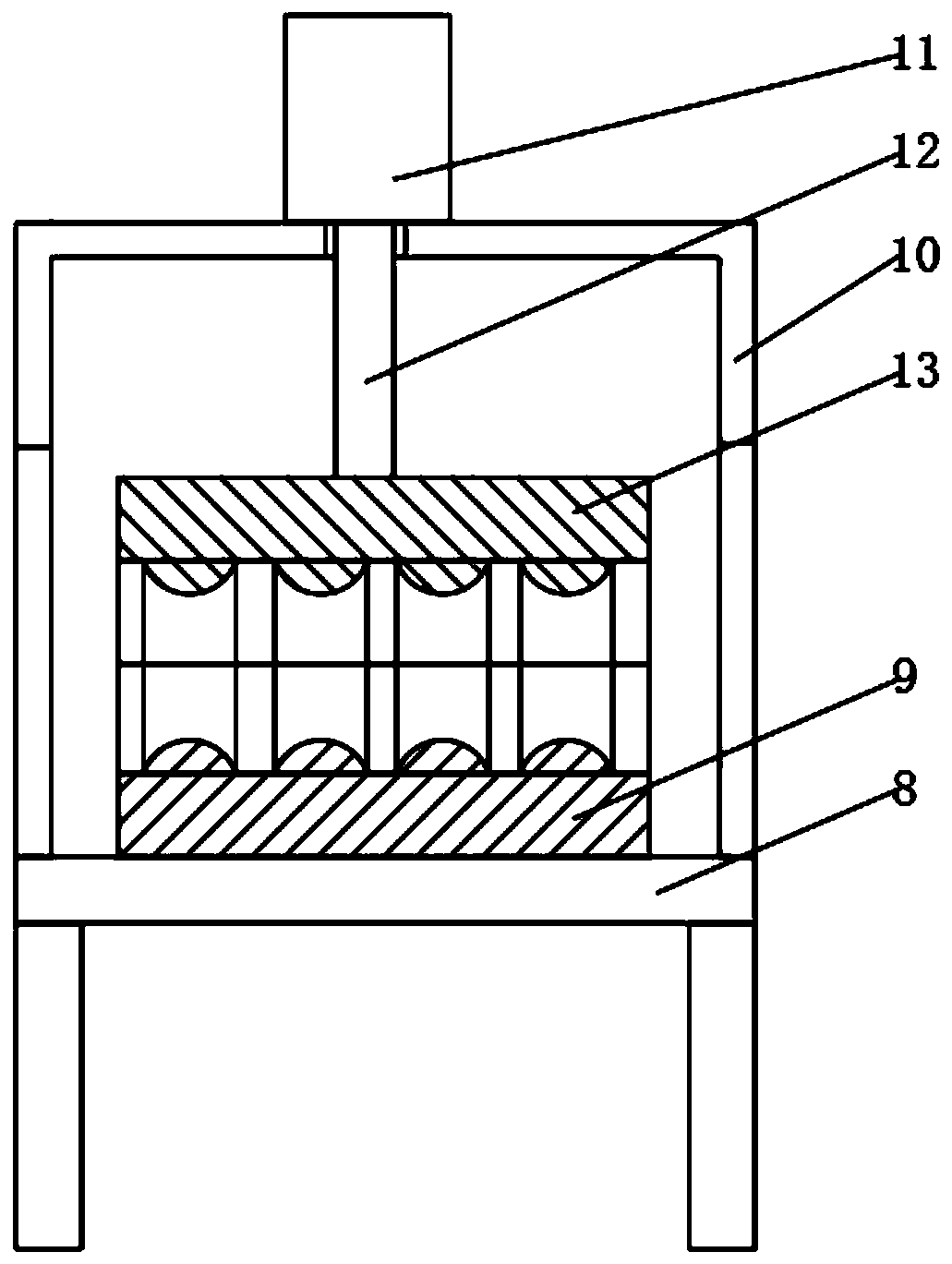

Image

Examples

Embodiment 1

[0033] As embodiment 1 of the present invention: a kind of production method of bending resistance high flexible towline cable, comprises the following steps:

[0034] The first step is to extrude the wire core raw material in the first extruder, add the water blocking paste raw material into the barrel of the water blocking paste machine and mix it. After the raw material is mixed, it will stick to the water blocking paste machine guide wheel to block water Paste, and make the wire core 1 and nylon wire 4 coated with the core layer 2 pass through the die head of the water blocking paste machine, and then adhere the water blocking paste to the guide wheel of the water blocking paste machine to realize the water blocking of the wire core 1 processing, and forming a water blocking layer 3;

[0035] In the second step, the water-blocking processed cables are input into the second extruder, and rubber is filled on the extruder, and the rubber is extruded to form a protective inner...

Embodiment 2

[0042] As embodiment 2 of the present invention: a kind of production method of bending resistance high flexible towline cable, comprises the following steps:

[0043]The first step is to extrude the wire core raw material in the first extruder, add the water blocking paste raw material into the barrel of the water blocking paste machine and mix it. After the raw material is mixed, it will stick to the water blocking paste machine guide wheel to block water Paste, and make the wire core 1 and nylon wire 4 coated with the core layer 2 pass through the die head of the water blocking paste machine, and then adhere the water blocking paste to the guide wheel of the water blocking paste machine to realize the water blocking of the wire core 1 processing, and forming a water blocking layer 3;

[0044] In the second step, the water-blocking processed cables are input into the second extruder, and rubber is filled on the extruder, and the rubber is extruded to form a protective inner ...

Embodiment 3

[0051] As embodiment 3 of the present invention: a kind of production method of bending resistance high flexible towline cable, comprises the following steps:

[0052] The first step is to extrude the wire core raw material in the first extruder, add the water blocking paste raw material into the barrel of the water blocking paste machine and mix it. After the raw material is mixed, it will stick to the water blocking paste machine guide wheel to block water Paste, and make the wire core 1 and nylon wire 4 coated with the core layer 2 pass through the die head of the water blocking paste machine, and then adhere the water blocking paste to the guide wheel of the water blocking paste machine to realize the water blocking of the wire core 1 processing, and forming a water blocking layer 3;

[0053] In the second step, the water-blocking processed cables are input into the second extruder, and rubber is filled on the extruder, and the rubber is extruded to form a protective inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com