Free-form surface spectrometer optical system and design method

An optical system and spectrometer technology, applied in spectrometry/spectrophotometry/monochromator, optical radiometry, using diffractive elements to generate spectra, etc. Unfavorable processing, weak F-number and field of view adaptability, etc., achieve the effect of strong aberration correction ability, strong distortion correction ability, and widening layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

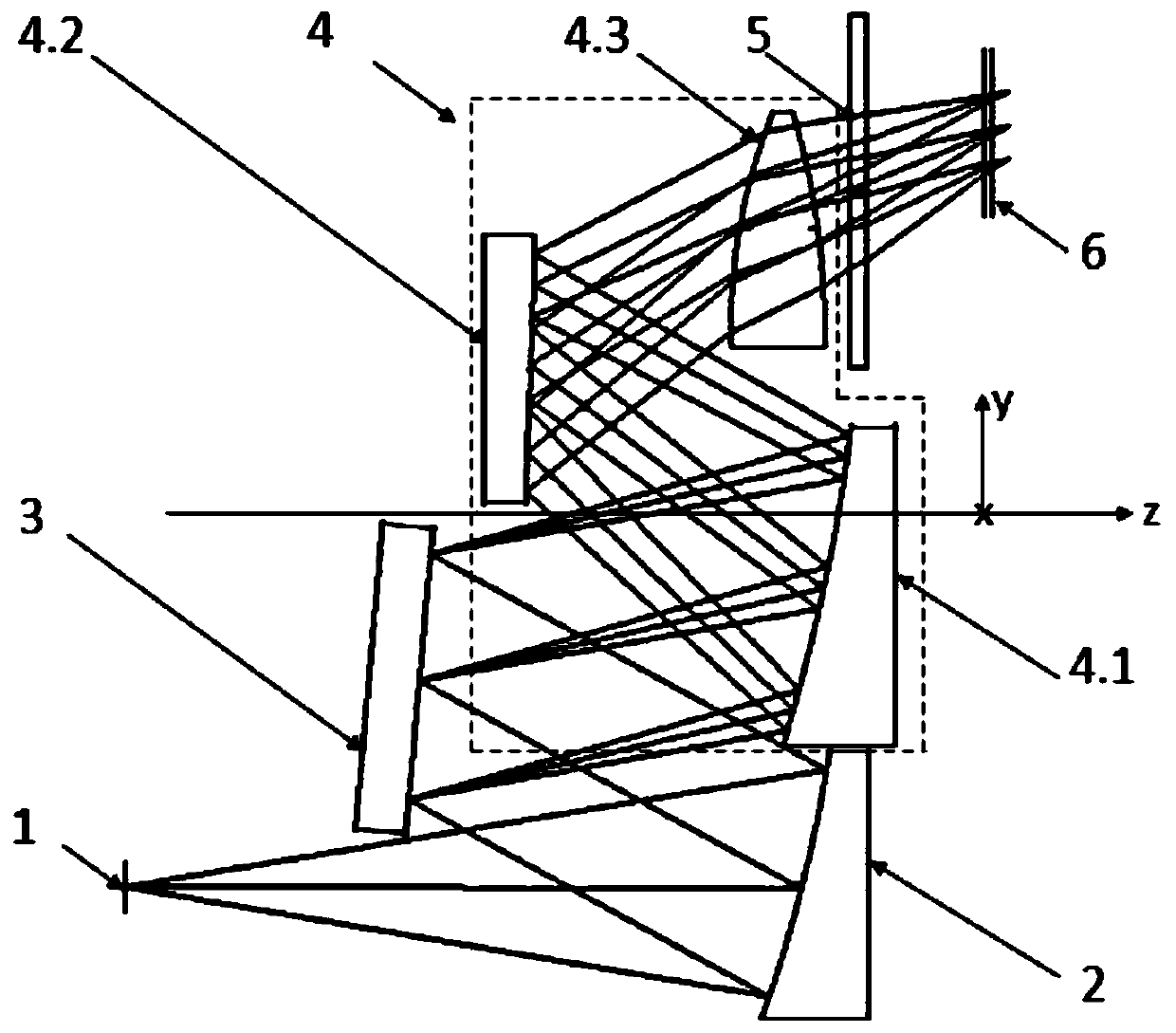

[0014] The following is based on figure 1 , give a better embodiment of the present invention and elaborate:

[0015] To design a short-medium wave infrared free-form surface spectrometer, the size of the detector array used is 512 elements × 320 elements, and the pixel size is 25 μm × 25 μm. The design index requirements are listed in Table 1.

[0016] Table 1

[0017] Spectral range F number Horizontal magnification Slit length Dispersion width 1.0-3.4μm 3.0 -1× 12.8mm 8.0mm

[0018] Design data are listed in Table 2.

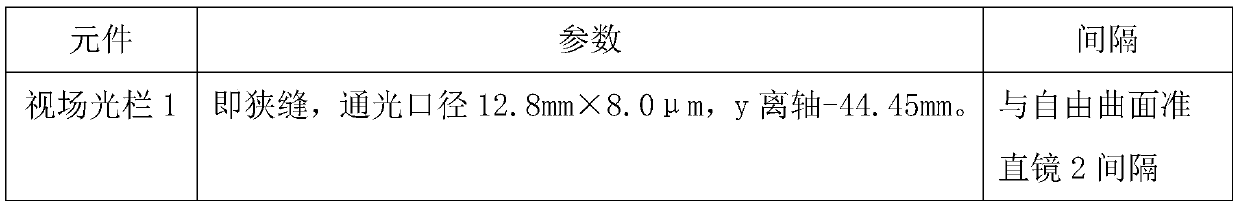

[0019] Table 2

[0020]

[0021]

[0022]

[0023] The design result is: the object space telecentricity of the spectrometer. The spectrometer normalizes 0 field of view, 0.707 field of view and 1 field of view, and the rms diameter of the spot diagram representing wavelengths of 1.0 μm, 2.2 μm and 3.4 μm is less than 5.6 μm, and the pixel size is less than 25 μm. At the Nyquist cut-off frequency of 20pl / mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com