Method for Improving Spline Accuracy of Torsion Bar Shaft and Its Products

A shaft spline and torsion bar technology, which is applied in the processing field of the spline at the end of the torsion bar shaft, achieves the effects of convenient operation, improved coaxiality, and improved straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

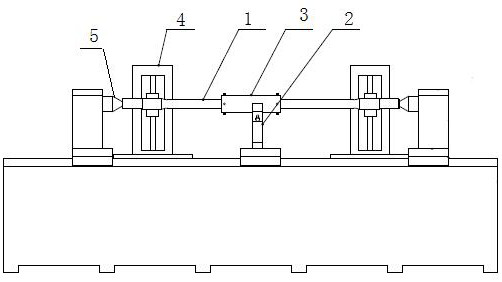

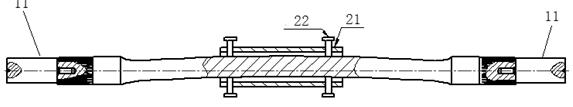

[0027] Combine below Figure 1 to Figure 2 Embodiments of the present invention are described in detail.

[0028] The method for improving the spline accuracy of the torsion bar shaft is characterized in that the torque is transmitted to the middle section of the torsion bar shaft 1 to drive the torsion bar shaft 1 to rotate, and the splines at both ends of the torsion bar shaft are synchronously processed by a hobbing cutter of a double-headed gear machine tool , by fine-tuning the coaxiality and circular runout at both ends of the torsion bar shaft 1 and improving the straightness and stiffness of the torsion bar shaft 1 before processing, the machining accuracy of the splines at both ends of the torsion bar shaft 1 is improved, and the number of splines at both ends of the torsion bar shaft 1 is reduced. The deviation of the splines, thereby improving the precision series of the splines at both ends of the torsion bar shaft 1.

[0029] In the method for improving the splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com