A rh refining method for reducing the temperature drop of molten steel and cooling steel in a vacuum chamber

A vacuum chamber and cold steel technology, applied in the field of iron and steel metallurgy, can solve the problems of large temperature drop of molten steel, carburization of molten steel, large volume, etc., to reduce the temperature drop of molten steel, increase the temperature of refractory materials, and increase the decarburization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

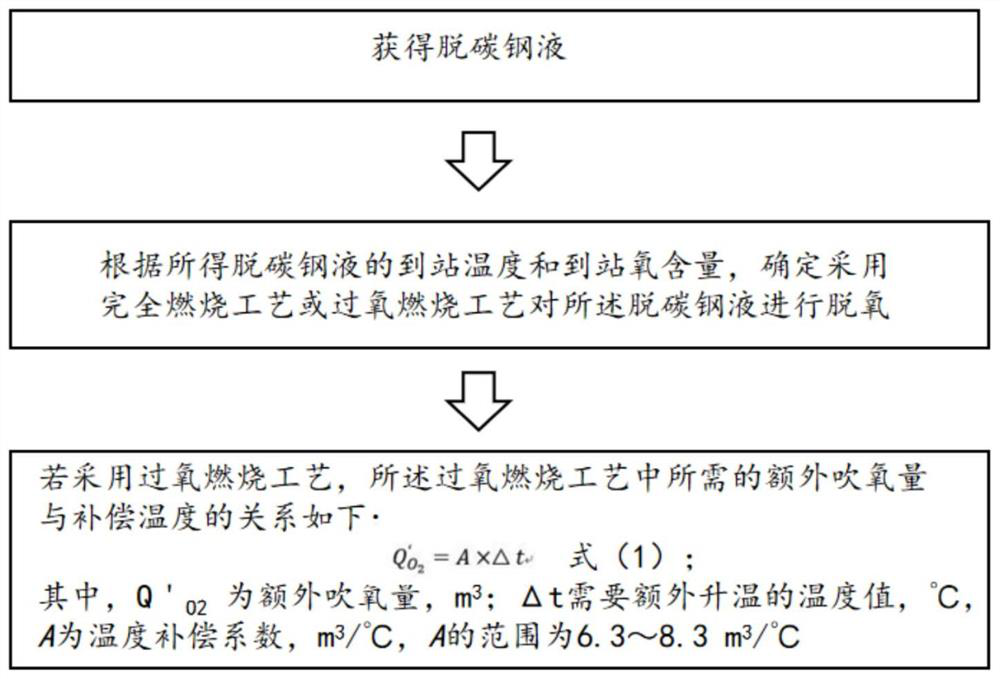

Method used

Image

Examples

Embodiment 1

[0069] The carbon content of the steel product smelted in this embodiment is ≤0.003%, the converter adopts a low-temperature tapping process, the tapping temperature is 1649°C, and the tapping amount is 218t;

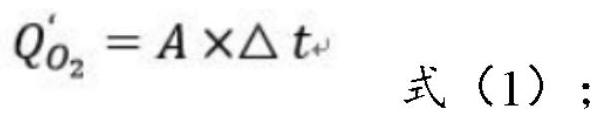

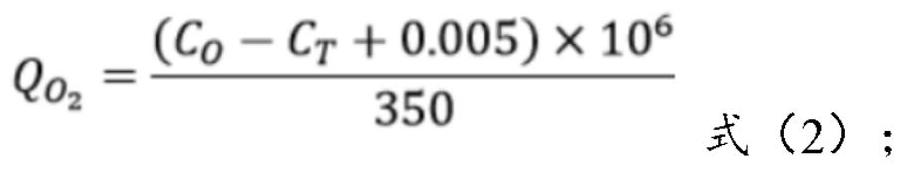

[0070] After the ladle enters the station, the temperature at the station is 1602°C, the carbon at the station is 0.03%, the oxygen at the station is 376ppm, and the carbon content at the end of RH is 0.0015%. Forced decarburization is used for decarburization by blowing oxygen. According to the formula, the amount of oxygen blowing is 68m 3 During the forced decarburization period, the position of the top gun is dynamically controlled from 7.5-6.5-5.5-4.5m from high to low. The oxygen blowing volume of each gun position is 17m 3 , the circulating argon flow control is less than 2200NL / min;

[0071] After the forced decarburization and oxygen blowing, the lowest gun position of 4.5m remains unchanged, and oxygen and gas are injected for combustion. The gas medium is cok...

Embodiment 2

[0075] The carbon content of the steel product smelted in this embodiment is ≤0.003%, the converter adopts a low-temperature tapping process, the tapping temperature is 1641°C, and the tapping amount is 221t;

[0076] After the ladle enters the station, the temperature at the station is 1594°C, the carbon at the station is 0.033%, the oxygen at the station is 289ppm, and the carbon content at the end of RH is 0.0015%. Forced decarburization and oxygen blowing are used for decarburization. According to the formula, the amount of oxygen blowing is 76m 3 During the forced decarburization period, the position of the top gun is dynamically controlled from 7.5-6.5-5.5-4.5m from high to low, and the oxygen blowing volume of each gun position is 19m 3 , the circulating argon flow control is less than 2200NL / min;

[0077] After the forced decarburization and oxygen blowing, the lowest gun position of 4.5m remains unchanged, and oxygen and gas are injected for combustion. The gas medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com