Surface coating for storage battery grid and preparation method of storage battery positive grid for deep circulation

A surface coating, battery technology, applied in battery electrodes, coatings, electrode carriers/current collectors, etc., can solve the problem that the improvement effect of maintenance-free sealed lead-acid batteries is not good enough, and improve charging acceptance and contact deterioration. Slow, prolonged cycle life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Lead-calcium alloy is used to cast the basic grid, and the specific composition is: by mass percentage, 0.08% Ca (calcium), 1.2% Sn (tin), 0.03% Al (aluminum), and the balance is Pb (lead). After the grid is cast, soak in a boric acid solution with a mass percentage of 1%, the solution temperature is 55±10°C, and the soaking time is 6s. Ultrasonic cleaning, using water-based cleaning agent, frequency 50KHz, cleaning temperature 40°C, cleaning time 5min, after cleaning, immerse in a mixed solution of antimony trioxide, tin oxide, bismuth oxide, saturated aqueous sodium silicate solution and sulfuric acid, of which three 1.8% by weight of antimony oxide, 0.2% by weight of tin oxide, 0.02% by weight of bismuth oxide, 6% by weight of saturated sodium silicate aqueous solution, and the balance is dilute sulfuric acid with a density of 1.45g / ml, mixed solution The temperature is 50°C, the immersion plating time is 30s, and high temperature aging is carried out after immersion...

Embodiment 2

[0038] Lead-calcium alloy is used to cast the basic grid, and the specific composition is: by mass percentage, 0.08% Ca (calcium), 1.2% Sn (tin), 0.03% Al (aluminum), and the balance is Pb (lead). After the grid is cast, soak in a boric acid solution with a mass percentage of 1.05%, the solution temperature is 55±10°C, and the soaking time is 3s. Ultrasonic cleaning, using water-based cleaning agent, frequency 90KHz, cleaning temperature 70°C, cleaning time 1min, after cleaning, immerse in a mixed solution of antimony trioxide, tin oxide, bismuth oxide, saturated aqueous sodium silicate solution and sulfuric acid. 0.45% by weight of antimony oxide, 0.05% by weight of tin oxide, 0.1% by weight of bismuth oxide, 4% by weight of saturated sodium silicate aqueous solution, and the balance is dilute sulfuric acid with a density of 1.08g / ml, mixed solution The temperature is 20°C, the immersion plating time is 120s, after immersion plating, high temperature aging is carried out, the...

Embodiment 3

[0046] Conduct the following tests:

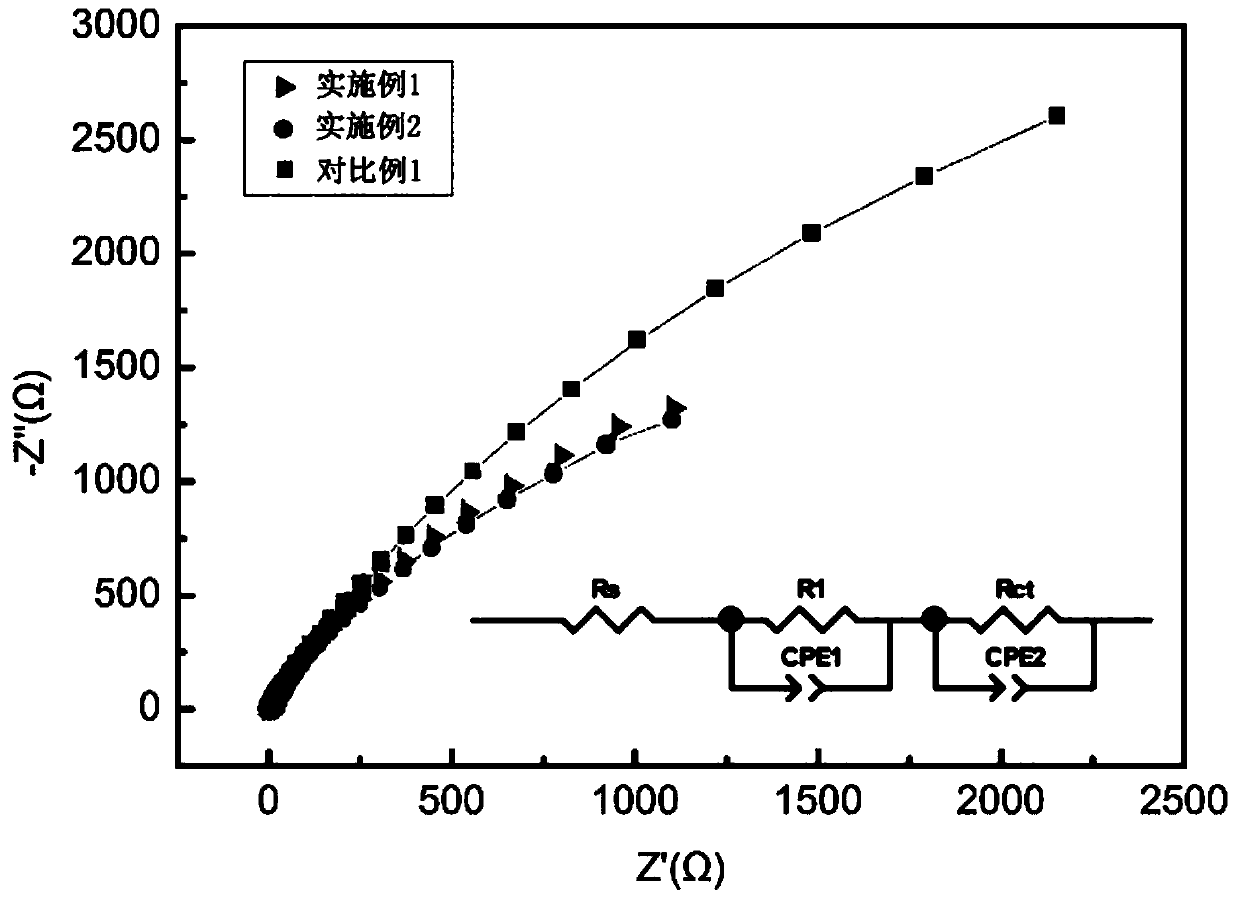

[0047] 1. After the grid is made, use the electrochemical workstation to test the transfer resistance of the finished grid of Example 1, Example 2 and Comparative Example 1. The test results are as follows: figure 1 As shown: the grid transfer resistance of Comparative Example 1 is significantly higher than that of Example 1 and Example 2, which proves that the electrical properties of the grids treated in Examples 1 and 2 are significantly better than those of Comparative Example 1.

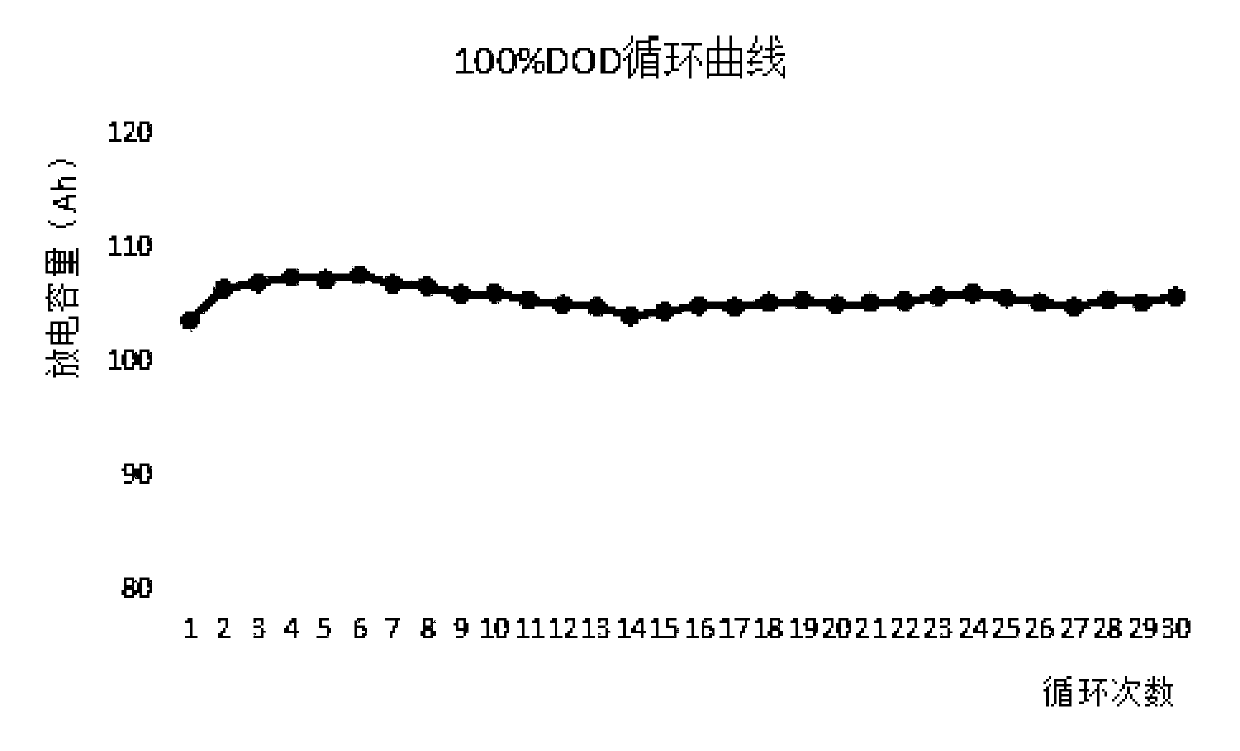

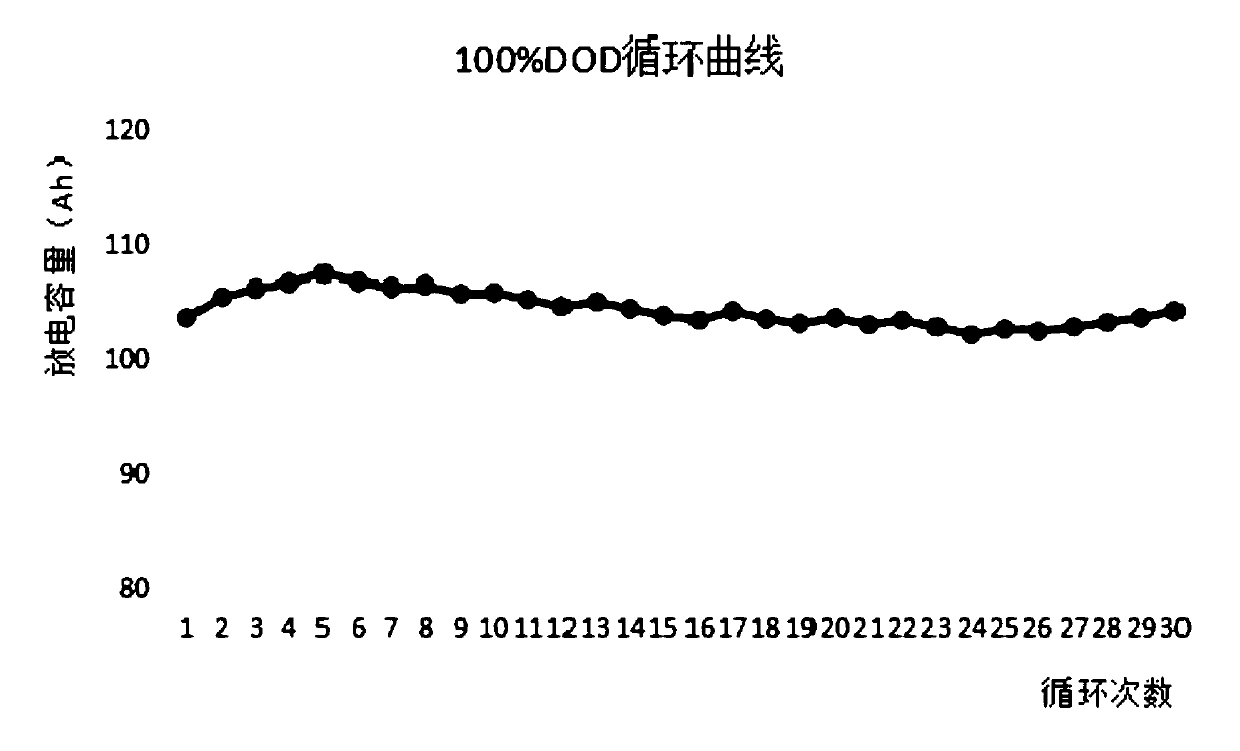

[0048] 2. Use the same lead paste, curing and drying process to make a positive plate of the same specification by using the same lead paste, curing and drying process to make a total of 5 kinds of finished grids in Examples 1 and 2, and Comparative Examples 1 to 3, and combine them with the same negative plate to make a 12V100Ah sample battery of the same specification. Carry out 30 times of 100% DOD cycle test, the specific test method: in the environment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com