Agricultural nitrogen-containing pollution gas real-time monitoring system and real-time monitoring method

A real-time monitoring system and pollution gas technology, applied in the field of agricultural information, can solve the problems of fast sensitivity decay, high temperature and humidity influence, zero drift, etc., to eliminate the influence of interfering gases, improve sensitivity and accuracy, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

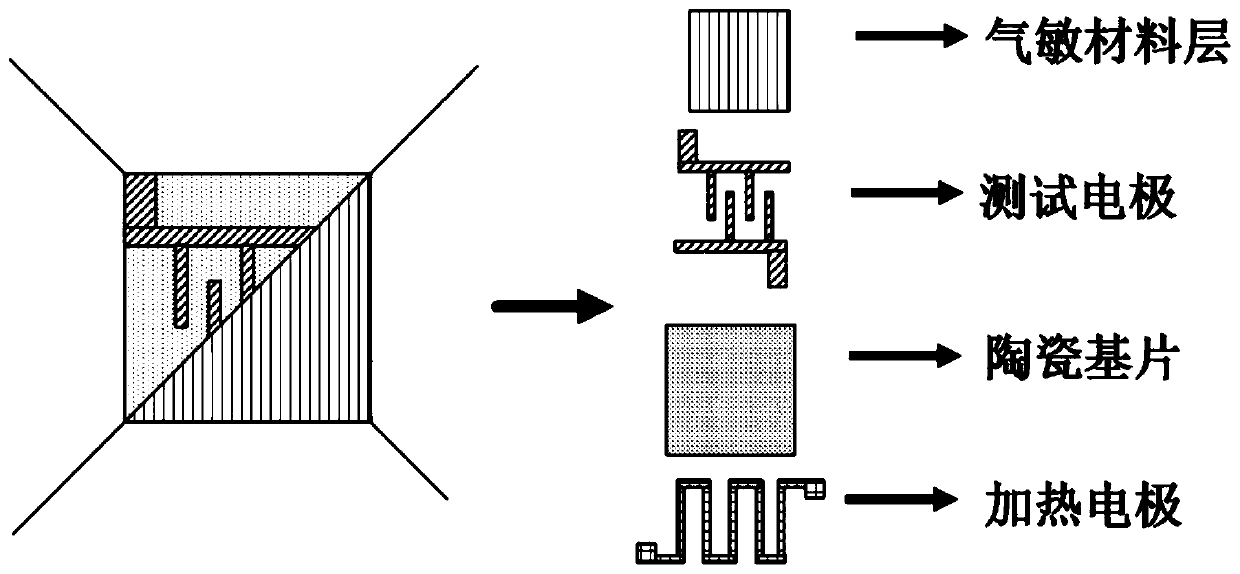

[0059] In the present invention, the obtained second NO 2 The sensor preferably includes a substrate, a heating electrode arranged on the back side of the substrate, a test electrode arranged on the front side of the substrate and a gas-sensitive material layer coated on the front side of the substrate, with a structure such as figure 1 As shown; the substrate is preferably a ceramic substrate; the test electrode is preferably an interdigital electrode; the thickness of the gas-sensitive material layer is preferably 20-40 μm. In the present invention, the second NO 2 The preparation method of the sensor preferably includes the following steps: preparing heating electrodes on the back of the substrate, preparing test electrodes on the front, and then printing the gas-sensitive material on the side of the substrate provided with the interdigitated electrodes by screen printing, and then sintering to obtain Second NO 2 Sensor; the sintering temperature is preferably 500°C, and ...

Embodiment 1

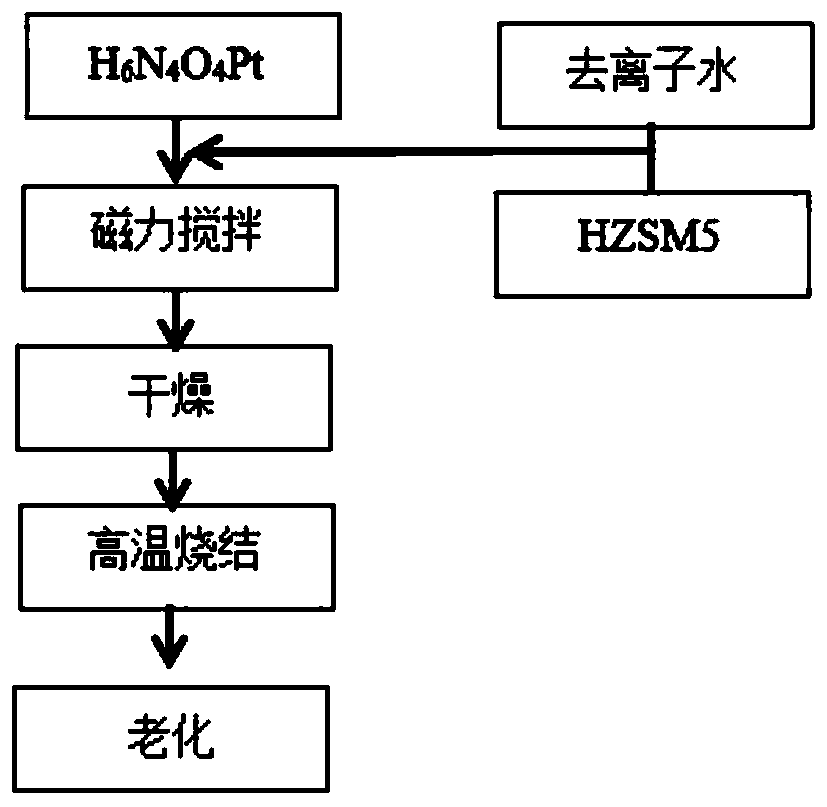

[0078] Using the impregnation method, the HZSM-5 molecular sieve powder is surface-catalyzed with noble metal Pt, thereby preparing the Pt-HZSM5 catalyst. The preparation process is as follows image 3 shown.

[0079] The specific method is:

[0080] (1) Take tetraammine platinum nitrate ([Pt(NH 3 ) 4 ](NO 3 ) 2 , purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), pour it into 10 mL of deionized water, stir at a constant temperature of 50 ° C for 30 min, and obtain a mother liquor with a concentration of 0.005 mol / L;

[0081] (2) HZSM-5 molecular sieve powder (purchased from Nankai University Catalyst Factory) was dispersed in deionized water to obtain a HZSM-5 molecular sieve solution with a concentration of 0.02g / mL; the prepared mother liquor was dropped into the HZSM-5 molecular sieve solution at a constant speed , controlling the loading of Pt in the final obtained catalyst to be 4wt%, and stirring at room temperature for 4h and then drying at 90°C fo...

Embodiment 2

[0085] Using the mother liquor method, the noble metal Pt is used to modify the surface of the nanostructured alumina powder, thereby preparing Pt-Al 2 o 3 Catalyst, the preparation process such as Image 6 shown.

[0086] Specific steps are as follows:

[0087] (1) Weigh ammonium tetraammine platinum nitrate (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.) according to the required ratio, pour it into a mixed solution of 120 μL water and 100 μL glycerin, and oscillate ultrasonically for 40 minutes until it is completely dissolved. Prepare the mother liquor whose concentration is 0.005mol / L;

[0088] (2) Weigh the required amount of nano-scale Al 2 o 3 (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.), after fully grinding for ten minutes, it was added to the mother liquor (controlling the loading of Pt in the final obtained catalyst was 4wt%), continued grinding for ten minutes, and placed in the box after taking it out. Sintered at 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com