Preparation method of polyamine type efficient desizing agent

A desizing agent and polyamine-type technology, which is applied in the field of preparation of polyamine-type high-efficiency desizing agents, can solve the problems of size coagulation, etc., and achieve the effects of reducing burden, good scale inhibition effect, and preventing re-staining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

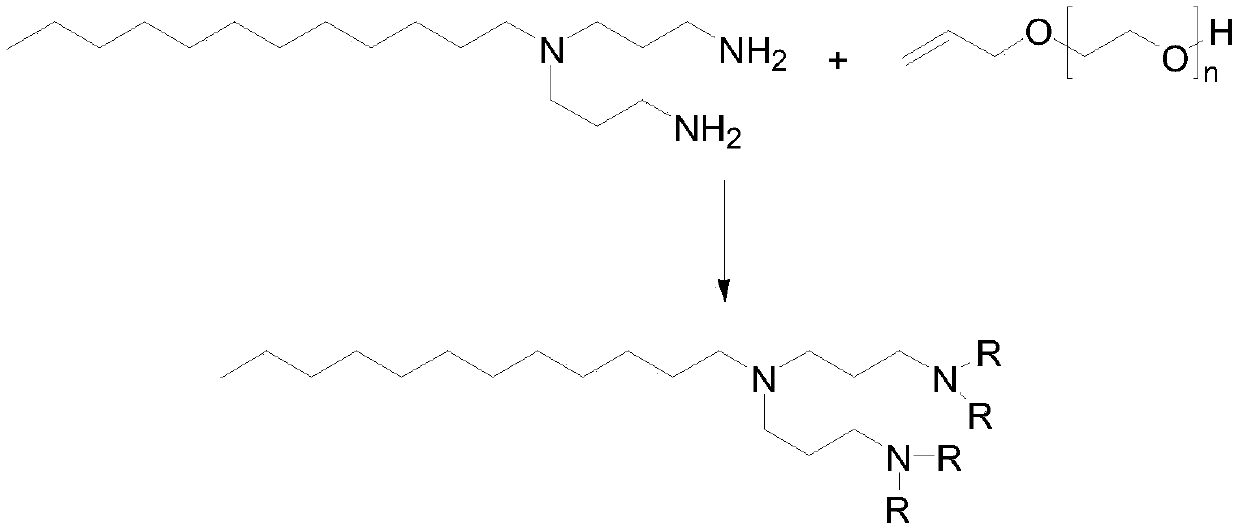

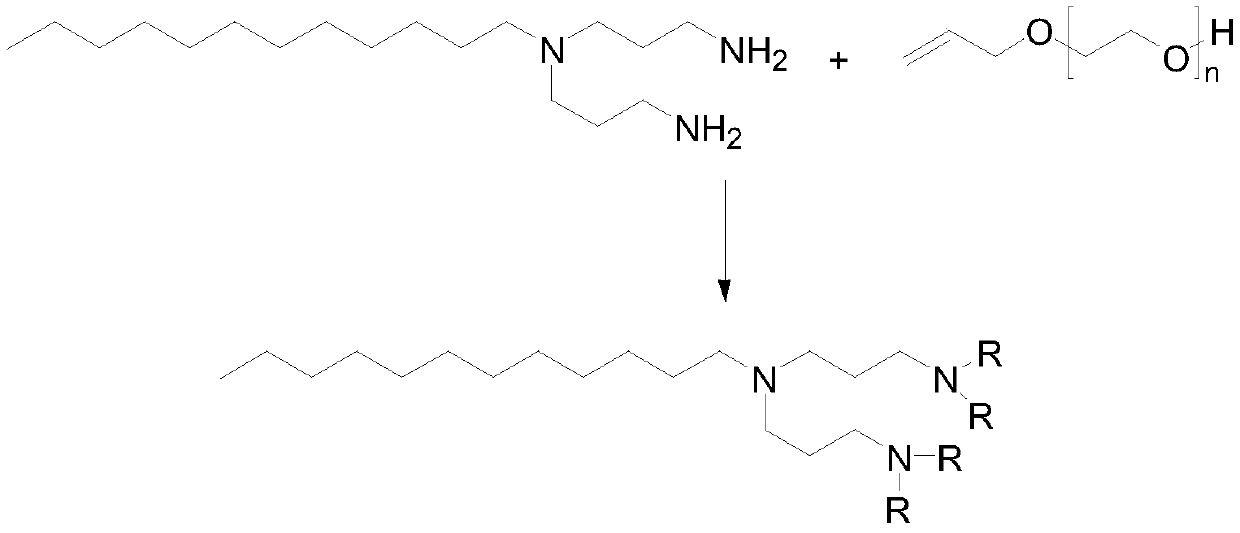

[0015] Example 1: Add 300 parts of laurylamine dipropylenediamine, 450 parts of allyl polyethylene glycol with a number average molecular weight of 350, and 150 parts of isopropanol into a reaction vessel, heat up to 65°C and keep it warm for 4 hours After that, the temperature was raised to 85°C, the vacuum was turned on, and the temperature was kept at -0.08MPa for 1 hour, and the temperature was lowered to below 50°C to discharge to obtain laurylamine dipropylenediamine polyoxyethylene ether.

[0016] 8 parts of sodium polyaspartate, 20 parts of laurylamine dipropylene diamine polyoxyethylene ether, 2 parts of sodium gluconate, and 70 parts of water to obtain a polyamine type high-efficiency desizing agent.

Embodiment 2

[0017] Example 2: 300 parts of laurylamine dipropylene diamine, 400 parts of allyl polyethylene glycol with a number average molecular weight of 500, and 140 parts of ethanol were added to the reaction vessel, and the temperature was raised to 70°C for 6 hours of heat preservation reaction. Raise the temperature to 80°C, turn on the vacuum, keep the temperature at -0.08MPa for 1.5 hours, cool down to below 50°C, and discharge to obtain laurylamine dipropylenediamine polyoxyethylene ether.

[0018] 6 parts of sodium polyaspartate, 20 parts of laurylamine dipropylenediamine polyoxyethylene ether, 4 parts of sodium gluconate, and 70 parts of water to obtain a polyamine type high-efficiency desizing agent.

Embodiment 3

[0019] Example 3: Add 300 parts of laurylamine dipropylenediamine, 600 parts of allyl polyethylene glycol with a number average molecular weight of 600, and 180 parts of isopropanol into the reaction vessel, heat it up to 70°C and keep it warm for 6 hours. , the temperature was raised to 85°C, the vacuum was turned on, the temperature was kept at -0.09MPa for 1.5 hours, the temperature was lowered to below 50°C, and the material was discharged to obtain laurylamine dipropylenediamine polyoxyethylene ether.

[0020] 6 parts of sodium polyaspartate, 25 parts of laurylamine dipropylene diamine polyoxyethylene ether, 4 parts of sodium gluconate, and 80 parts of water to obtain a polyamine type high-efficiency desizing agent.

[0021] 1. Experimental method:

[0022] (1) Fabric:

[0023] 300T polyester woven fabric, the warp and weft deniers are both 44.4dtex, and the warp and weft densities are 185 threads / 2.54cm and 115 threads / 2.54cm respectively.

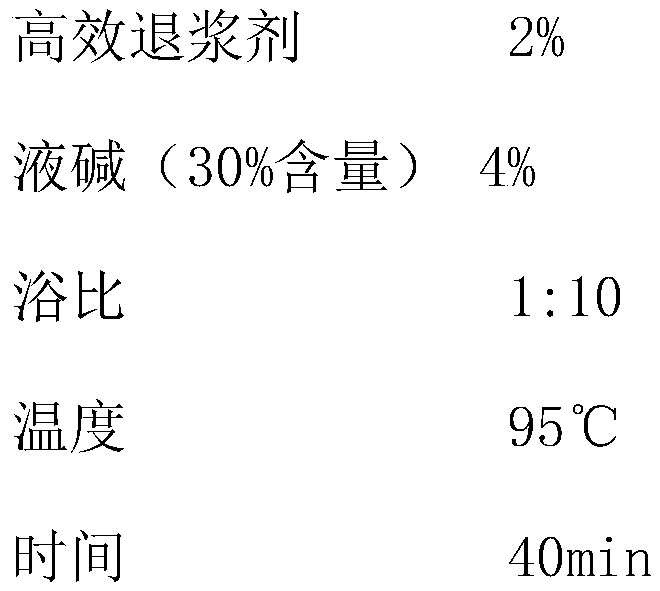

[0024] (2) Desizing process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com