Hydrophilic polystyrene macroporous resin for streptomycin sulfate extraction and synthesis method thereof

A polystyrene resin, streptomycin sulfate technology, applied in chemical instruments and methods, other chemical processes, preparation of sugar derivatives, etc., can solve problems such as toxic side effects, hearing loss in patients, and restrictions on the application of streptomycin, etc. Achieve stable quality, excellent performance and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of synthetic method of hydrophilic polystyrene macroporous resin for streptomycin sulfate extraction, comprising the following steps:

[0029] S1, synthetic polystyrene resin macroporous white ball;

[0030] Water phase: Dissolve carboxymethyl cellulose, gelatin, and methylene blue in water at room temperature as the water phase;

[0031] Oil phase: The polymerized monomers are styrene and divinylbenzene, of which divinylbenzene accounts for 6% to 8% by mass, and the rest is styrene. After mixing the monomer and porogen, it becomes the oil phase. The porogen For 200# gasoline and white oil.

[0032] The mass ratio of 200# gasoline to white oil (1~3):5, and the mass ratio of porogen to monomer (0.5~1.0):1.

[0033] In the reactor with the water phase, heat the water phase to 55°C, add the oil phase to the reactor, the volume ratio of the water phase and the oil phase is (2-4):1, and disperse the oil phase into the water by stirring In the...

Embodiment 1

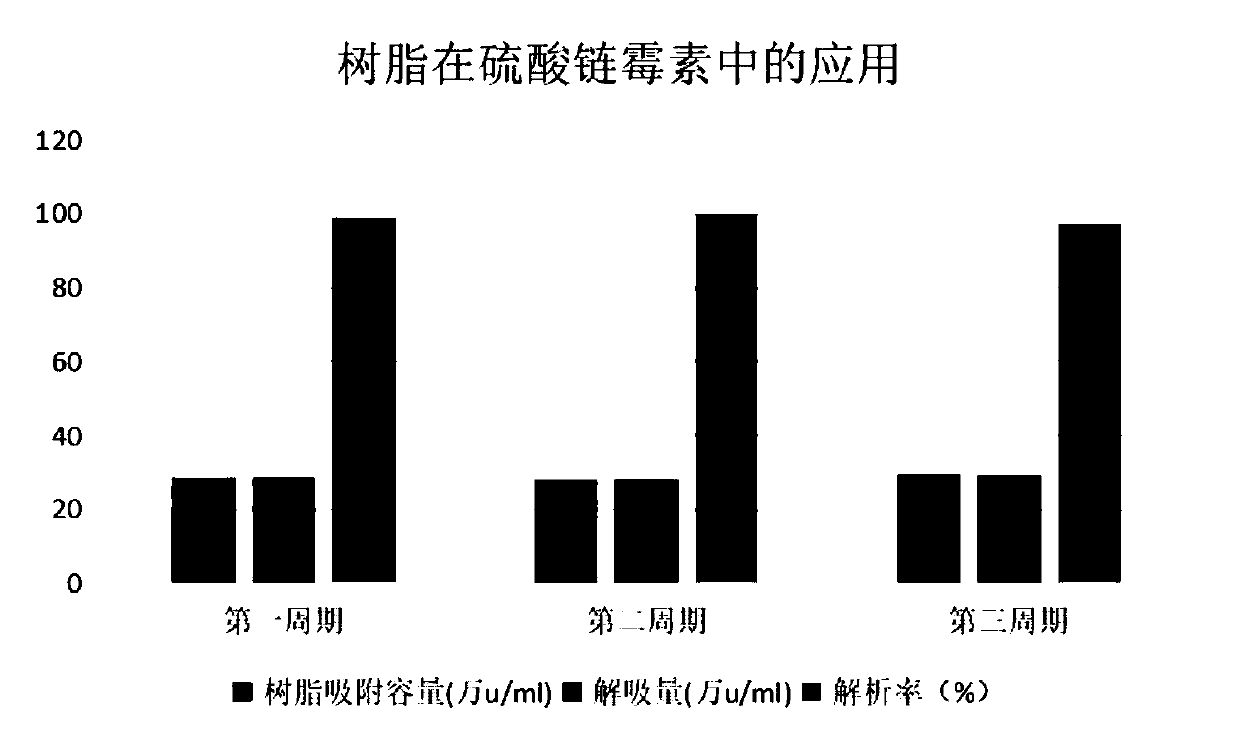

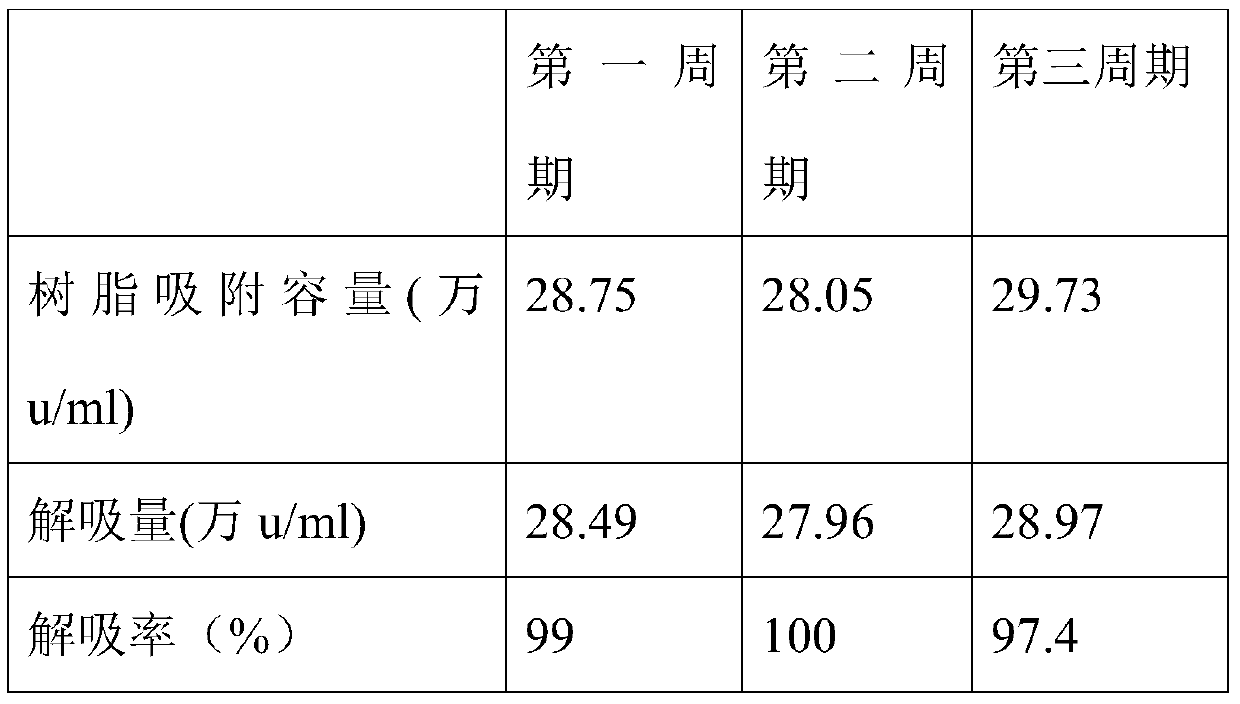

[0043] Hydrophilic polystyrene macroporous resin for streptomycin sulfate extraction and synthesis method

[0044] (1) Synthetic polystyrene resin macroporous white ball

[0045] Water phase: Dissolve carboxymethyl cellulose, gelatin, and methylene blue in water at room temperature as the water phase;

[0046] Oil phase: Polymerized monomers are styrene and divinylbenzene, of which divinylbenzene accounts for 7%, and the rest is styrene. After mixing the monomer and porogen, it becomes the oil phase, and the porogen is 200# gasoline And white oil, the mass ratio of 200# gasoline to white oil is 1:5, and the mass ratio of porogen to monomer is 0.5:1.

[0047] In the reactor with the water phase, heat the water phase to 55°C, add the oil phase to the reactor, the volume ratio of the water phase and the oil phase is 3.5:1, disperse the oil phase into the water phase by stirring, and control The particle size is 0.3-0.8mm, heat up to 70-80°C, react for 3 hours, continue to heat ...

Embodiment 2

[0055] Hydrophilic polystyrene macroporous resin for streptomycin sulfate extraction and synthesis method

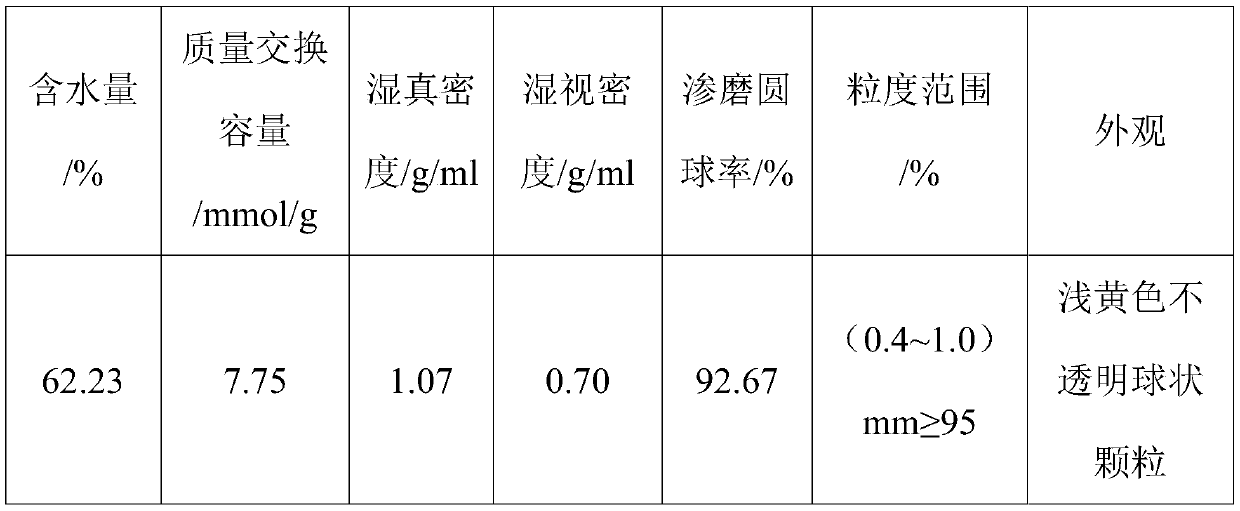

[0056] The degree of crosslinking of the synthetic polystyrene resin macroporous white spheres was adjusted to 8%, and other processes were as in Example 1.

[0057] The detection performance indicators are as follows

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| cation exchange capacity (mol) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com