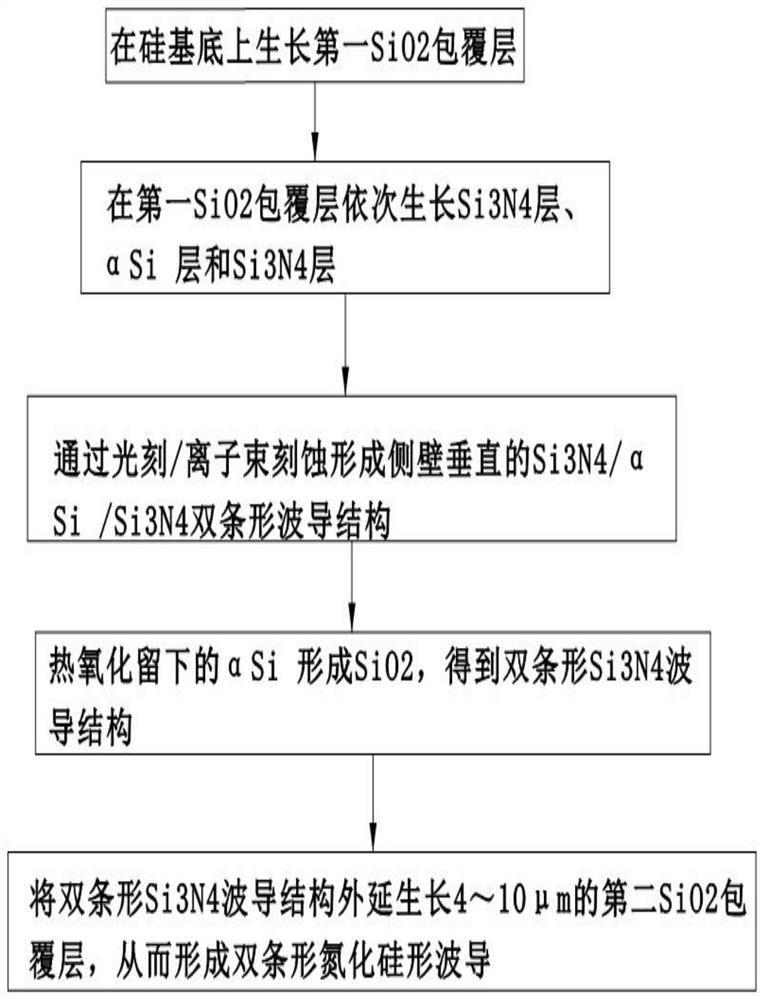

A double-strip silicon nitride waveguide and its preparation method

A technology of silicon nitride wave and silicon nitride, applied in the direction of optical waveguide light guide, light guide, instrument, etc., can solve the problem of low verticality, achieve the effect of improving verticality, avoiding process errors, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

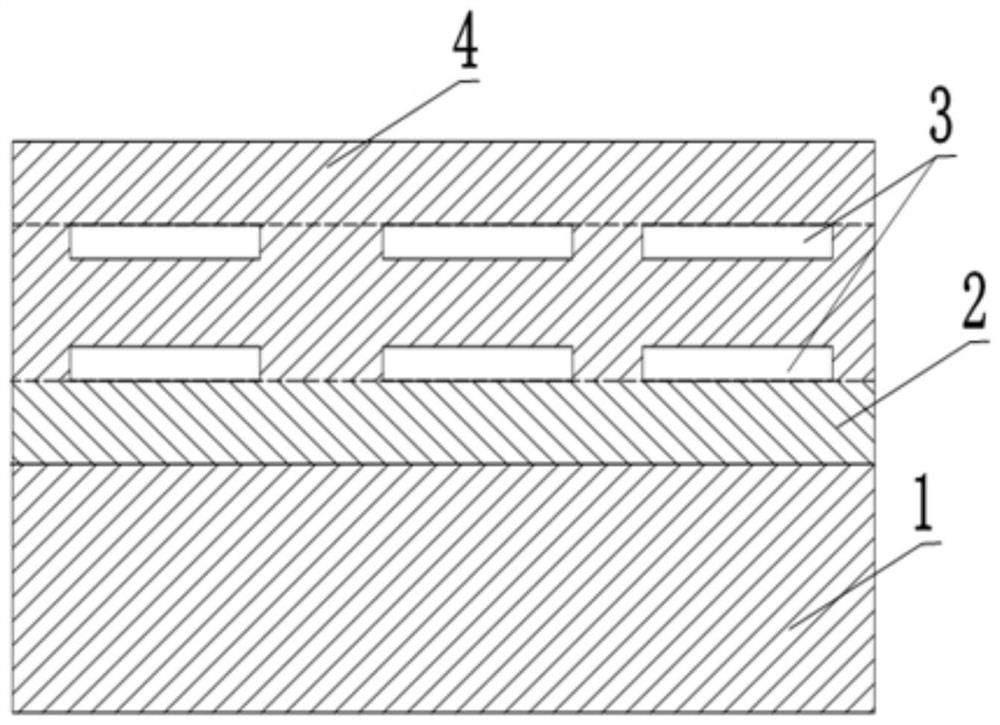

[0059] A dual strip silicon nitride waveguide comprising:

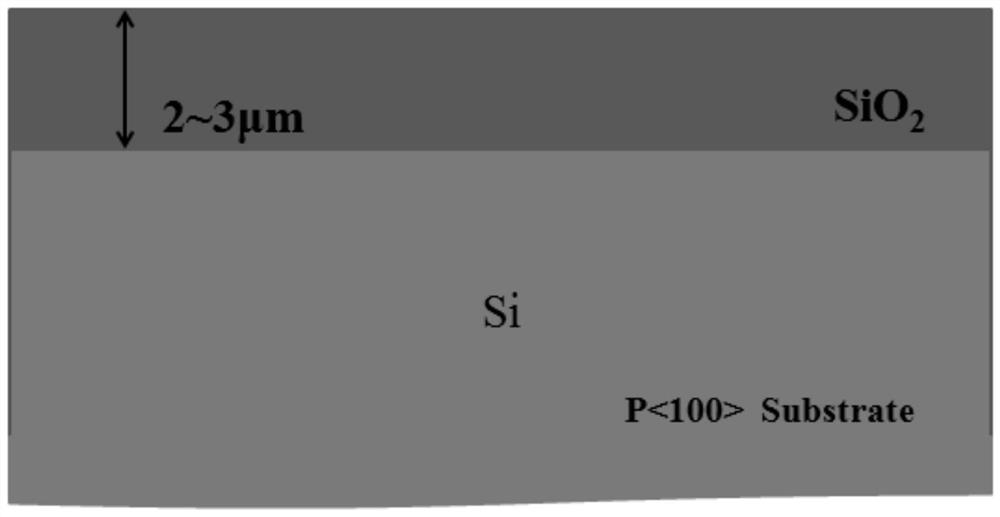

[0060] Silicon substrate 1;

[0061] The first SiO uniformly covered on the upper surface of the silicon substrate 2 cladding layer 2; the first SiO 2 The thickness of the cladding layer is 2-3 μm;

[0062] Located on the first SiO 2 Bistripe Si on the upper surface of the cladding 3 N 4 waveguide structure 3; the double-strip Si 3 N 4 Each Si of the waveguide structure 3 N 4 The thickness of the waveguide structure is 100-250nm; the double strip Si 3 N 4 The sidewall of the waveguide structure is perpendicular to the silicon substrate, and the double-striped Si 3 N 4 The upper and lower two Si of the waveguide structure 3 N 4 The corresponding sidewalls of the waveguide structure are aligned with each other; the double-strip Si 3 N 4 The waveguide structure is a vertically symmetrical structure with a pitch of 400nm-1.5μm.

[0063] The double bar Si 3 N 4 The waveguide structure is covered by a sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com