Chuck structure and semiconductor manufacturing apparatus including the same

A technology for manufacturing equipment and semiconductors, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as interference, and achieve the effect of preventing process errors and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

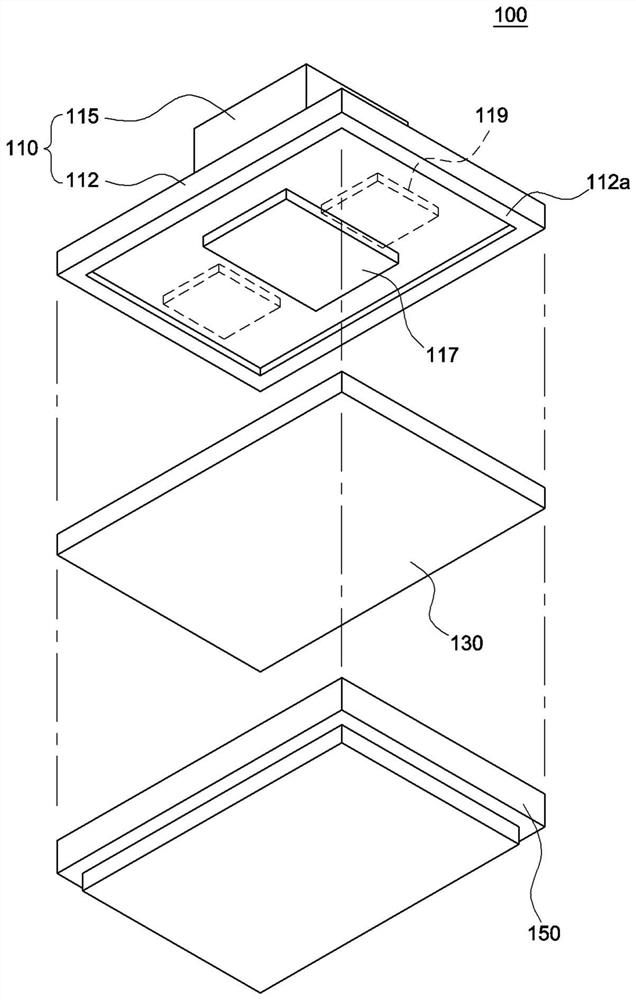

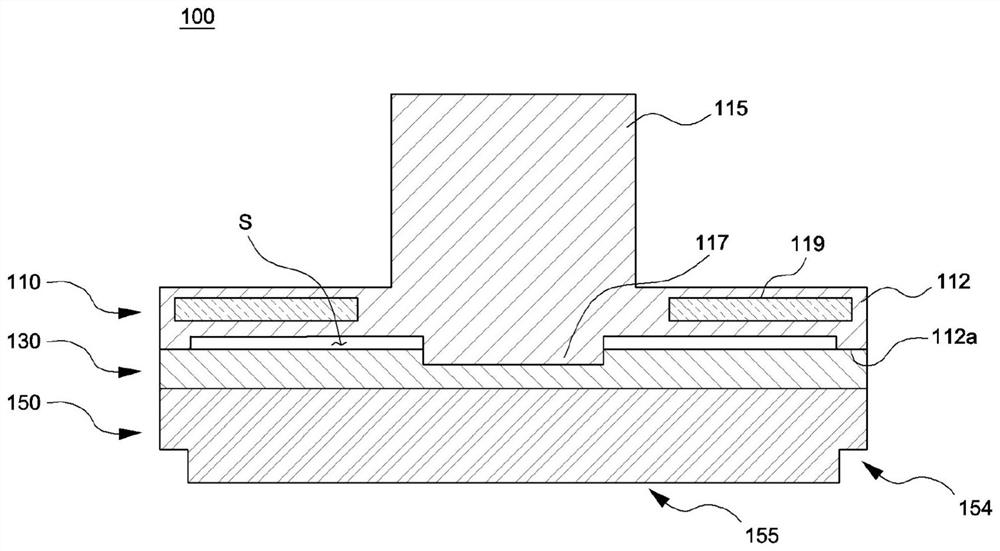

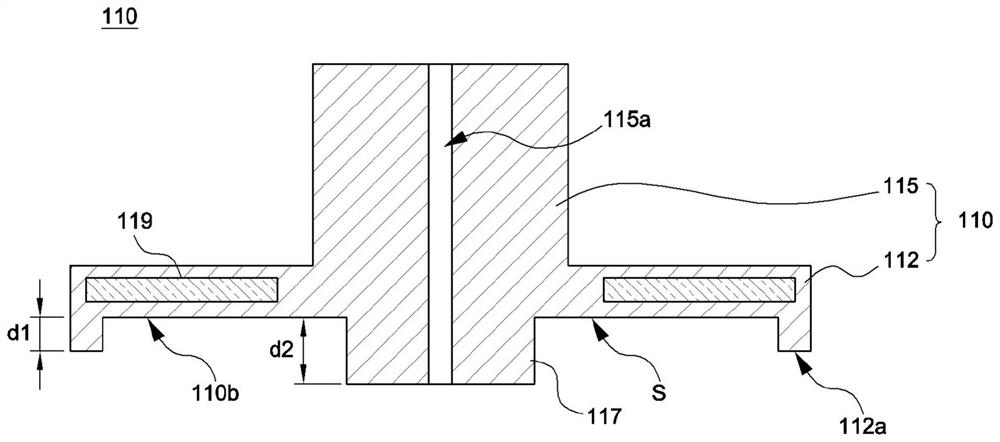

[0024] Various embodiments of the invention will be described in more detail with reference to the accompanying drawings. The Figures are schematic illustrations of various embodiments and intermediate structures. Likewise, variations in the configuration and shape of the illustrations as a result, for example, of manufacturing techniques and / or tolerances are contemplated. Accordingly, the described embodiments should not be construed as limited to the specific configurations and shapes shown herein but may include deviations in configurations and shapes without departing from the spirit and scope of the present invention as defined in the appended claims.

[0025] The invention is described herein with reference to cross-sectional and / or plan illustrations of embodiments of the invention. However, the embodiments of the present invention should not be construed as limiting the concept of the present invention. While a few embodiments of the present invention will be shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com