Double-strip-shaped silicon nitride waveguide and preparation method thereof

A technology of silicon nitride wave and silicon nitride, which is applied in the field of double-strip silicon nitride waveguide and its preparation, can solve the problem of low verticality, achieve the effects of improving verticality, avoiding process errors, and reducing absorption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

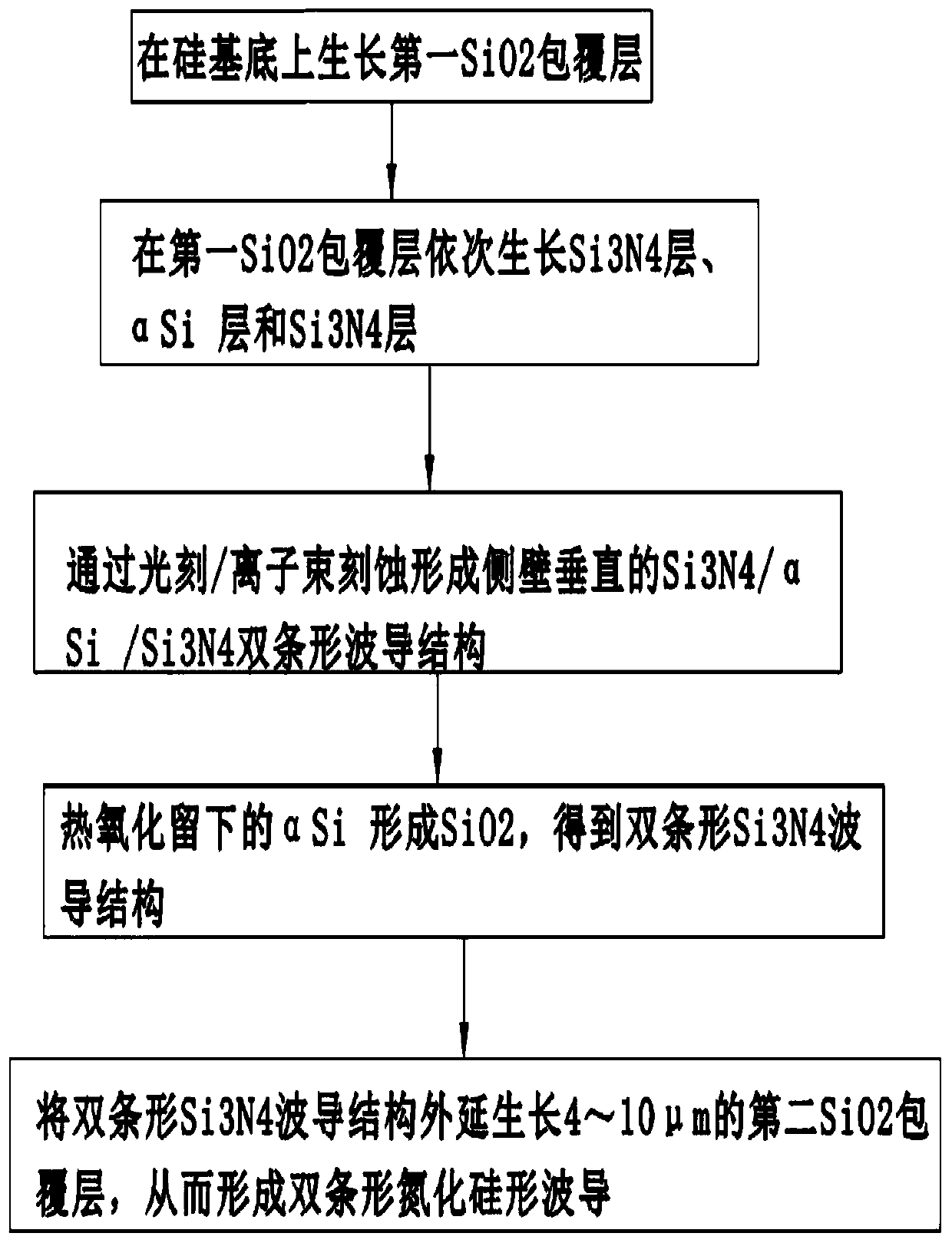

Method used

Image

Examples

Embodiment 1

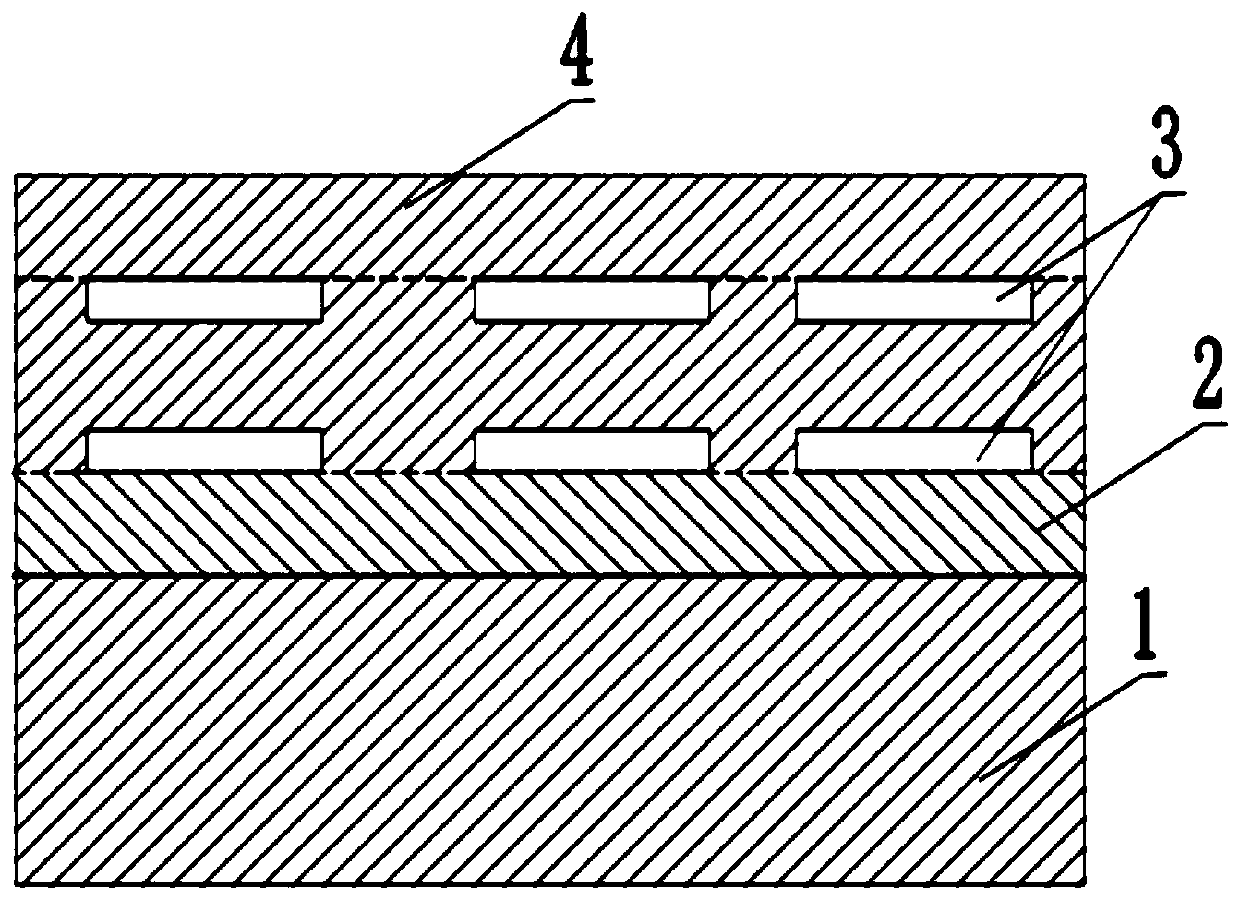

[0059] A dual strip silicon nitride waveguide comprising:

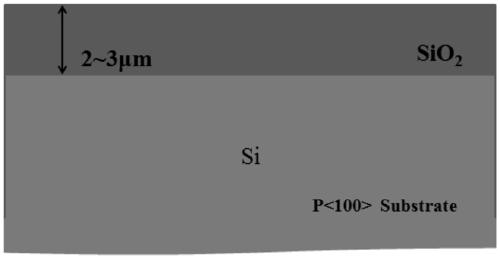

[0060] Silicon substrate 1;

[0061] The first SiO uniformly covered on the upper surface of the silicon substrate 2 cladding layer 2; the first SiO 2 The thickness of the cladding layer is 2-3 μm;

[0062] Located on the first SiO 2 Bistripe Si on the upper surface of the cladding 3 N 4 waveguide structure 3; the double-strip Si 3 N 4 Each Si of the waveguide structure 3 N 4 The thickness of the waveguide structure is 100-250nm; the double strip Si 3 N 4 The sidewall of the waveguide structure is perpendicular to the silicon substrate, and the double-striped Si 3 N 4 The upper and lower two Si of the waveguide structure 3 N 4 The corresponding sidewalls of the waveguide structure are aligned with each other; the double-strip Si 3 N 4 The waveguide structure is a vertically symmetrical structure with a pitch of 400nm-1.5μm.

[0063] The double bar Si 3 N 4 The waveguide structure is covered by a sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com