Multielement hard coating and electromagnetic enhancement magnetron sputtering preparation process thereof

A hard coating and magnetron sputtering technology, which is applied in metal material coating process, coating, sputtering plating, etc., can solve the problem of poor bonding force, stress accumulation, and low ionization rate of magnetron sputtering particles To achieve the effect of increasing the plasma density, lengthening the motion stroke, and improving the ionization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Multi-component Hard AlCrWSiN Coating with Single Composite Functional Layer

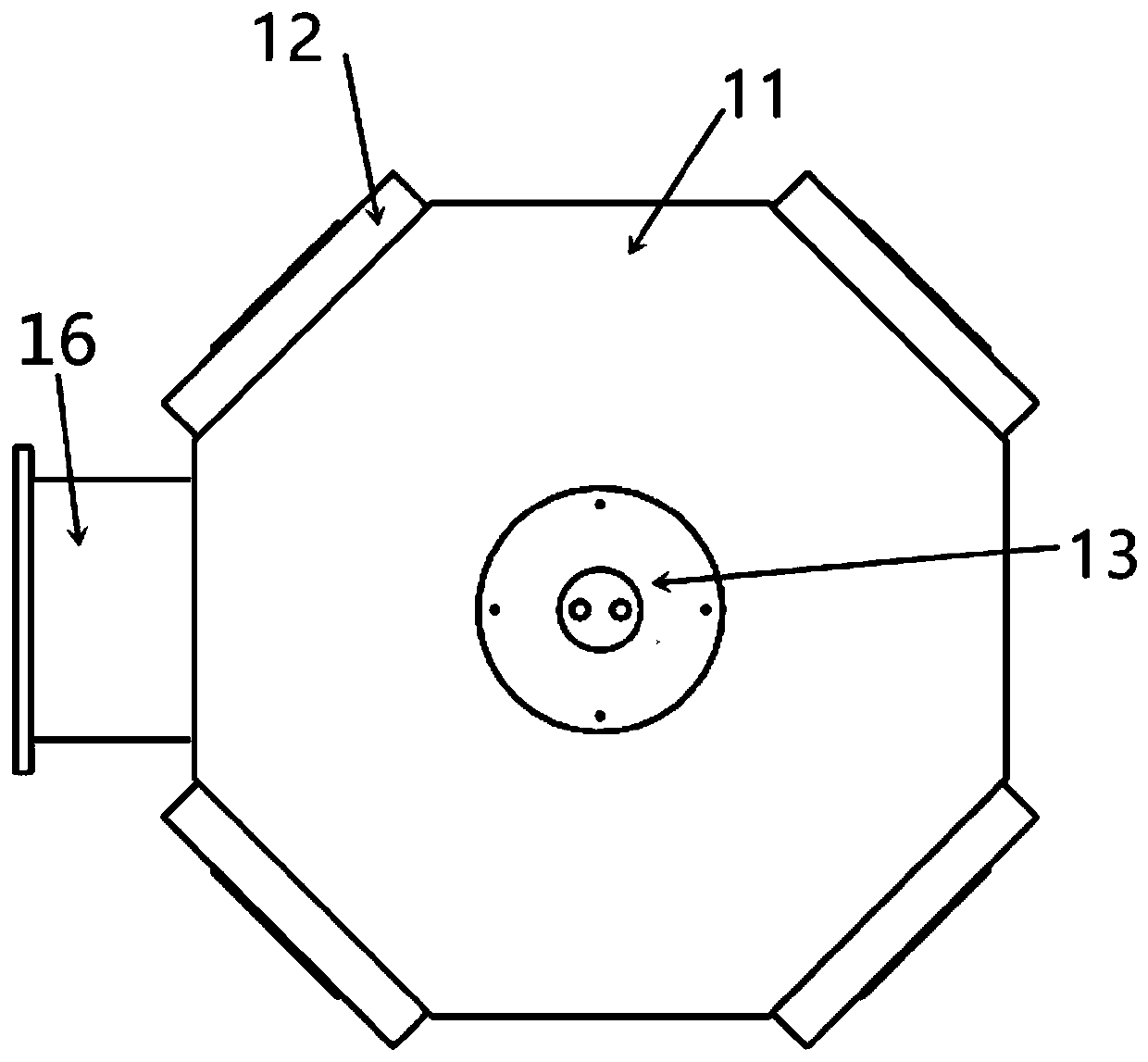

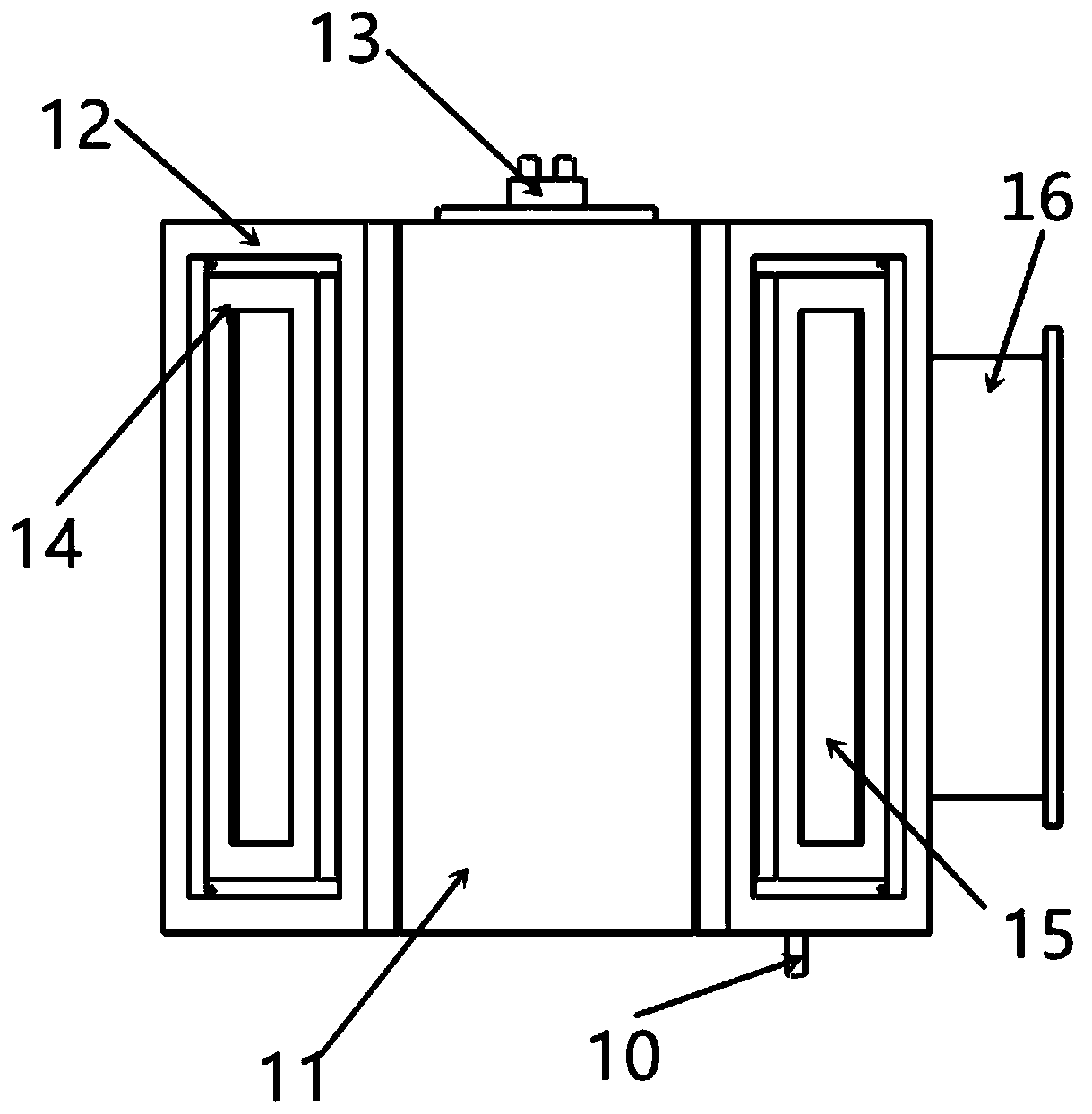

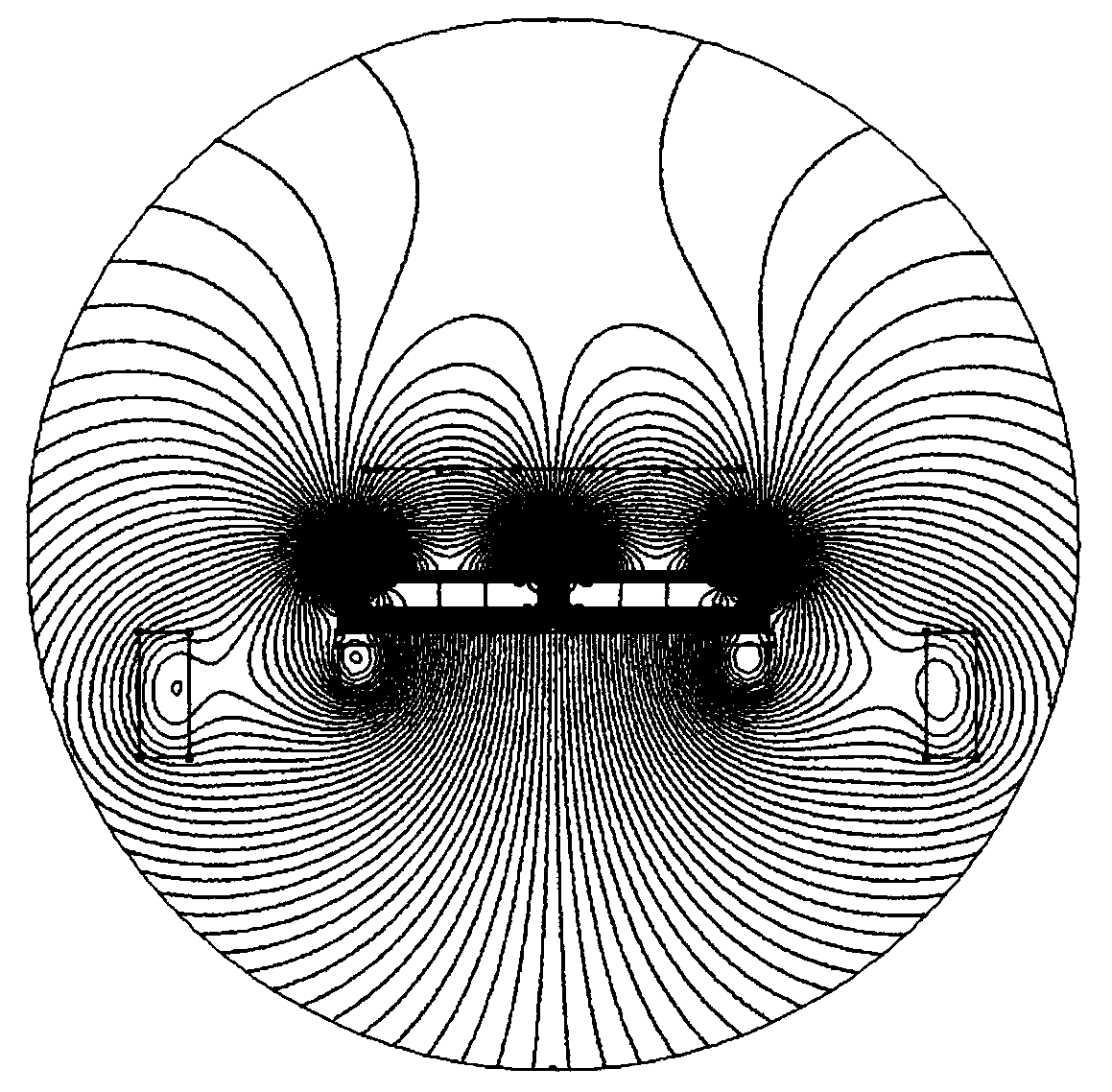

[0055] The coating equipment configuration of the multi-component hard coating of the single-layer composite coating functional layer is as follows. The electromagnetically enhanced magnetron sputtering cathode 15 used is four groups, of which two groups are equipped with alloy AlCr targets, two groups are equipped with AlCrWSi targets, and four groups The magnetron sputtering cathode 15 is equipped with electromagnetic enhancement coils 12, 14, and the cylindrical central anode 13 is assembled at the center of the top surface of the cavity. During the glow discharge process, electrons will be subjected to the electric field of the anode under the action of the annular closed magnetic field. During the movement of the electrons, they will collide with the process gas and sputtering particles, thereby ionizing the gas and sputtering particles. In this process, the closed magnetic field will gre...

Embodiment 2

[0075] Multi-layer hard coating of multi-layer composite functional layer

[0076] The coating equipment configuration of the multi-component hard coating of the multi-layer composite functional layer is as follows. The electromagnetically enhanced magnetron sputtering cathodes used are four groups, of which two groups are equipped with metal AlCr targets, two groups are equipped with TiSi targets, and four groups of magnetron sputtering cathodes are equipped with The emitter cathode is equipped with an electromagnetic enhancement coil, and the central anode is installed at the center of the upper end of the cavity. During the glow discharge process, electrons will be attracted to the water-cooled anode by the electric field of the anode under the action of the annular closed magnetic field. During the movement, it will collide with the process gas and sputtering particles, thereby ionizing. In this process, the annular closed magnetic field will greatly increase the free path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com