Epoxy resin liquid mixture and its uv delayed curing solid film

A technology of epoxy resin and novolac epoxy resin, which is applied in the direction of epoxy resin glue, novolak epoxy resin adhesive, adhesive, etc., can solve the problem of no bonding reliability and good UV delay epoxy structural adhesive film and other problems, achieve high bonding reliability, realize bonding reliability, and facilitate die-cutting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

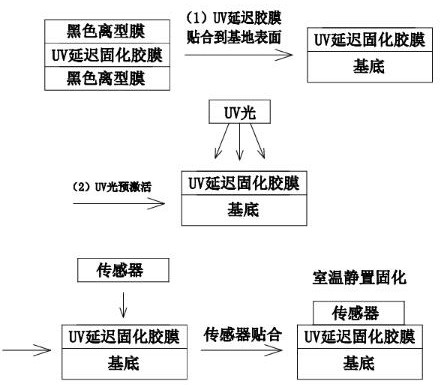

Image

Examples

Embodiment 1

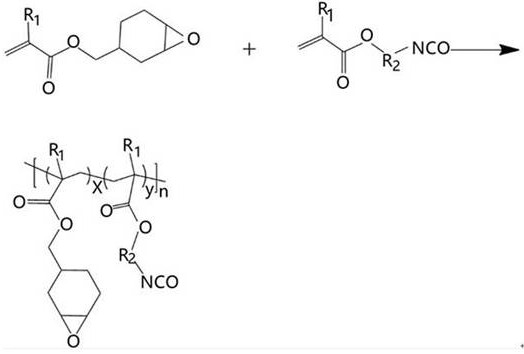

[0031] (1) Preparation of isocyanic acid modified cycloaliphatic epoxy resin:

[0032] The synthetic route of described isocyanic acid modified cycloaliphatic epoxy resin is shown in the following formula:

[0033]

[0034] Among them, R 1 for H, R 2 for -(CH 2 ) m -, x is 20, y is 5, n is 20, m is 1;

[0035] Add alicyclic epoxy acrylic monomers with double bonds and acrylic monomers with isocyanic acid into solvent B, add initiator A, react at a temperature of 40°C for 2 hours, then add a polymerization inhibitor, After purification, a solid isocyanate-modified cycloaliphatic epoxy resin can be obtained.

[0036] The alicyclic epoxy acrylic monomer with a double bond is 3,4-epoxycyclohexyl methacrylate; the acrylic monomer with isocyanate is isocyanoethyl methacrylate; The initiator A is benzoyl peroxide; the solvent B is cyclohexanone; and the polymerization inhibitor is 2,4,6-trinitrophenol (TNP).

[0037] (2) Preparation of epoxy resin liquid mixture:

[0038]M...

Embodiment 2

[0045] (1) Preparation of isocyanic acid modified cycloaliphatic epoxy resin:

[0046] The synthetic route of isocyanic acid modified cycloaliphatic epoxy resin is shown in the following formula:

[0047]

[0048] Among them, R 1 for CH 3 -, R 2 for - (CH 2 -O-CH 2 )m-, x is 100, y is 100, n is 200, m is 10;

[0049] Add alicyclic epoxy acrylic monomers with double bonds and acrylic monomers with isocyanic acid into solvent B, add initiator A, react at a temperature of 40°C for 2 hours, then add a polymerization inhibitor, Solid isocyanic acid modified cycloaliphatic epoxy resin can be obtained after purification;

[0050] The acrylic monomer of the alicyclic epoxy with double bond is 3,4-epoxycyclohexylmethyl methacrylate; the acrylic monomer with isocyanate is 2-(2-isocyanate Acid ethoxy) ethyl methacrylate; The initiator A is azobisisoheptanonitrile; The solvent B is dioxane, and the polymerization inhibitor is 1,4-benzoquinone (BQ) .

[0051] (2) Preparation of...

Embodiment 3

[0059] (1) Preparation of isocyanic acid modified cycloaliphatic epoxy resin:

[0060] The synthetic route of isocyanic acid modified cycloaliphatic epoxy resin is shown in the following formula:

[0061]

[0062] where R 1 for CH 3 -, R 2 for - (CH 2 -O-CH 2 ) m -, x is 50, y is 60, n is 100, m is 8;

[0063] Add alicyclic epoxy acrylic monomers with double bonds and acrylic monomers with isocyanic acid into solvent B, add initiator A, react at a temperature of 60°C for 4 hours, then add a polymerization inhibitor, Solid isocyanic acid modified cycloaliphatic epoxy resin can be obtained after purification;

[0064] The alicyclic epoxy acrylic monomer with a double bond is 3,4-epoxycyclohexylmethyl methacrylate; the acrylic monomer with isocyanate is isocyanoethyl acrylate; The initiator A is dimethyl azobisisobutyrate; the solvent B is chloroform; and the polymerization inhibitor is β-phenylnaphthylamine.

[0065] (2) Preparation of epoxy resin liquid mixture:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com