Current collector and application thereof

A technology of current collector and metal layer, applied in current collector and its application field, can solve the problems of low connection yield and high contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

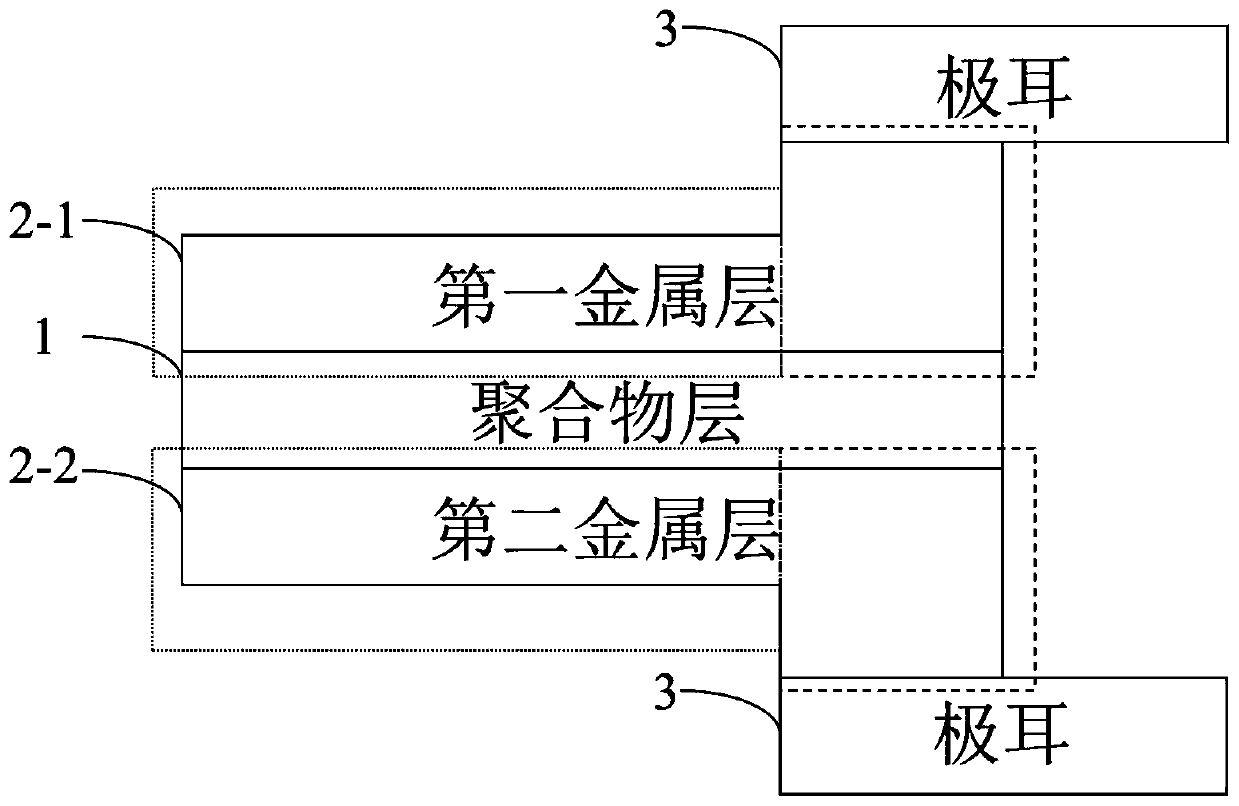

[0049] The current collector structure provided by this embodiment is as figure 1 As shown, the polymer layer is PET, the metal layer is aluminum, the thickness of the polymer PET layer is 6 μm, the thickness of the metal layer in the non-tab connection area is 1 μm, and the thickness of the metal layer in the tab connection area is 1.05 μm. The positive tab is welded on the tab connection area of the metal aluminum layer by ultrasonic welding, the thickness of the positive tab is 0.1mm, and the width is 6mm;

[0050] Use the LK-108A model tensile tester of Likong Instrument Technology Co., Ltd. to clamp the tab with a clamp, and then use the tensile tester to test the pulling force N that the tab is pulled off from the current collector. The width of the tab is D, which can be The tab welding strength F=N / D is calculated, and the result shows that the tab welding strength in this embodiment is 0.6 N / mm.

Embodiment 2

[0052] The current collector structure provided by this embodiment is as figure 1 As shown, the polymer layer is PET, the metal layer is aluminum, the thickness of the polymer PET layer is 6 μm, the thickness of the metal layer in the non-tab connection area is 1 μm, and the thickness of the metal layer in the tab connection area is 1.5 μm. The positive tab is welded on the tab connection area of the metal aluminum layer by ultrasonic welding, the thickness of the positive tab is 0.1mm, and the width is 6mm;

[0053] Using the same welding strength test method as in Example 1, the results show that the tab welding strength in this example is 1.1 N / mm.

Embodiment 3

[0055] The current collector structure provided by this embodiment is as figure 1 As shown, the polymer layer is PET, the metal layer is aluminum, the thickness of the polymer PET layer is 6 μm, the thickness of the metal layer in the non-tab connection area is 1 μm, and the thickness of the metal layer in the tab connection area is 2 μm. The way of welding is to weld the positive tab on the tab connection area of the metal aluminum layer, the thickness of the positive tab is 0.1mm, and the width is 6mm;

[0056] Using the same welding strength test method as in Example 1, the results show that the tab welding strength in this example is 1.6 N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com