Preparation method, product and application of vanadium-based positive electrode material for zinc-ion battery

A zinc-ion battery, cathode material technology, applied in electrode manufacturing, battery electrodes, nanotechnology for materials and surface science, etc., can solve the problems of poor conductivity, unstable layered structure, etc. Rate performance, rich material source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]First weigh 0.1182g ammonium metavanadate, so that it is fully dissolved in 20mL deionized water, and then take 0.94mL ethylenediamine, under the condition of magnetic stirring, it is slowly titrated to the above solution, after stirring evenly, 1M HCl is added dropwise to the above solution, adjusting the pH to 4.0. The above solution was poured into a high-pressure water hot kettle, moved to the oil bath pot, and the magnetic stirring was maintained under the condition of 120 °C oil bath for 6 h, so that the ethylenediamine was fully polymerized. Finally, the collected precipitate was filtered and the precipitate was placed in a vacuum drying box at 80 °C for 12 to 15 hours to obtain vanadium-based cathode material C 2 H 8 N 2 V 7 O 16 。

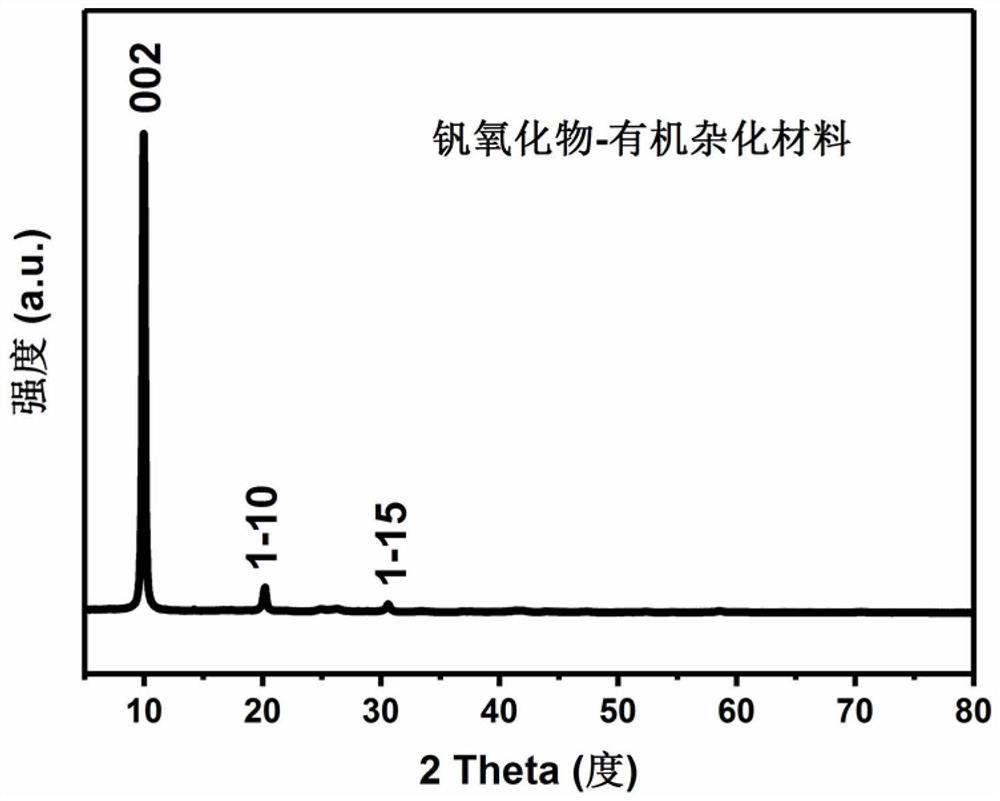

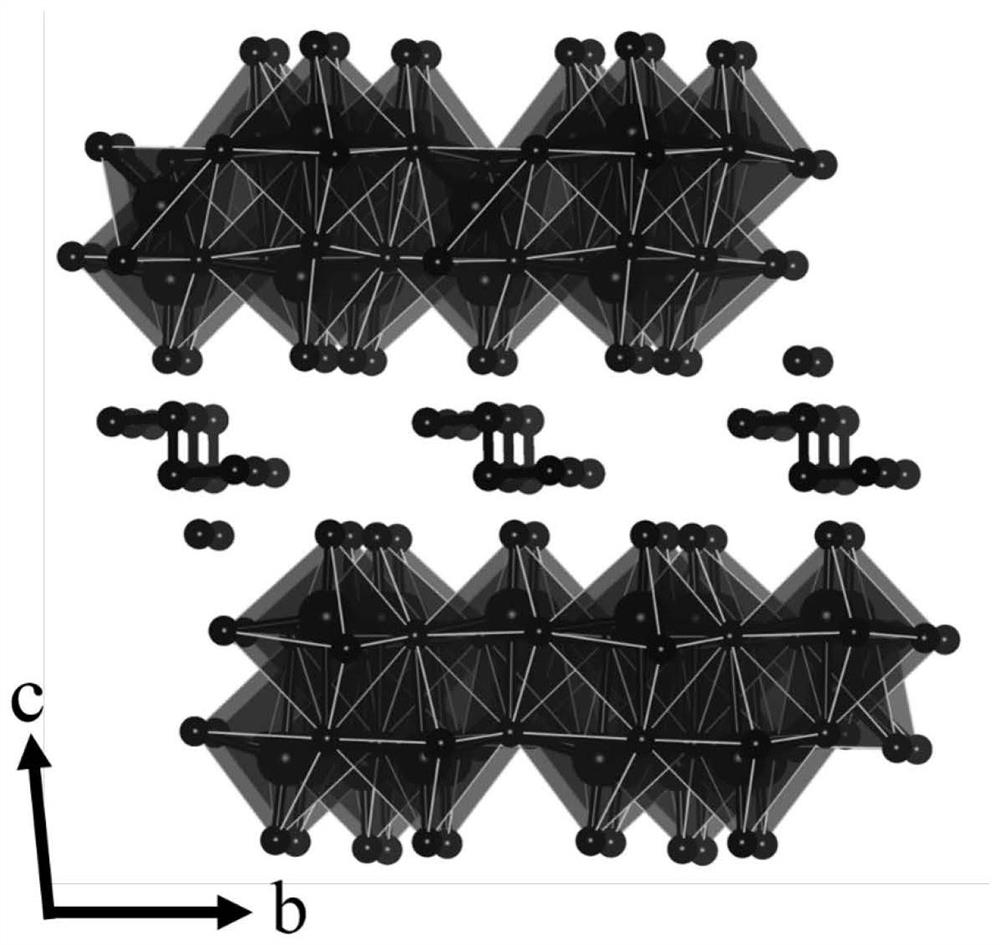

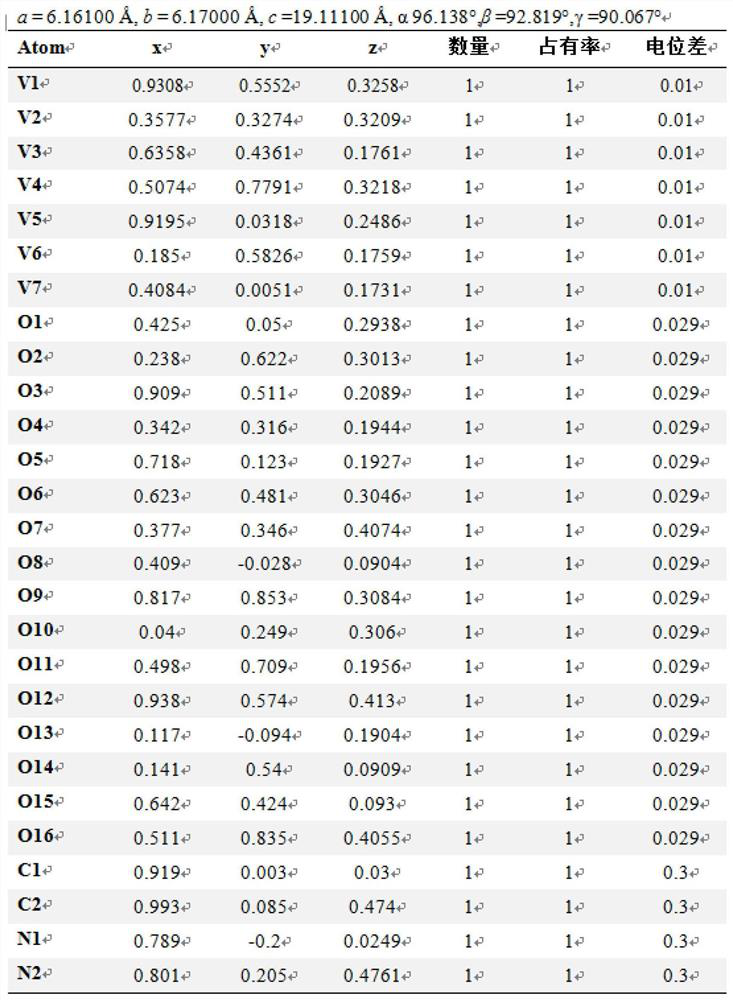

[0030] Vanadium-based cathode material C prepared in the present embodiment 2 H 8 N 2 V 7 O 16 XRD analysis is performed, the results of which are as follows Figure 1 as shown, from Figure 1 It can be seen that the characteristic peaks o...

Embodiment 2

[0035] First weigh 0.0697g acetylaceton oxyvanadium, so that it is fully dissolved in 20mL deionized water, and then take 0.63mL of ethylenediamine, under the condition of magnetic stirring, it is slowly titrated into the above solution, stirred evenly, 1.5MHCl is added dropwise to the above solution, adjust the pH to 5.0. The above solution was poured into a high-pressure water hot kettle, moved to the oil bath pot, and the magnetic stirring was maintained under the condition of 140 °C oil bath for 6 h, so that the ethylenediamine was fully polymerized in situ. Finally, the collected precipitate was filtered and the precipitate was placed in a vacuum drying box at 70 °C for 15 hours to obtain vanadium-based cathode material.

[0036] Illuminate C 2 H8 N 2 V 7 O 16 The mass ratio of the material, acetylene black, binder is 7:2:1 to weigh the raw material, after mixing, fully grind and mix well, and then add NMP (NMP and the mass ratio of the binder is 1:0.02326) to make the ground...

Embodiment 3

[0039] First weigh 0.2912g of vanadium pentoxide, so that it is fully dissolved in 20mL deionized water, and then take 1.16mL of ethylenediamine, under the condition of magnetic stirring, it is slowly titrated into the above solution, stirred evenly, 1M HCl is added dropwise to the above solution, adjusted pH to 3.0. The above solution was poured into a high-pressure water hot kettle, moved to the oil bath pot, and the magnetic force was stirred for 4 h under the condition of 160 °C oil bath, so that the ethylenediamine was fully polymerized in situ. Finally, the collected sediment was filtered and the sediment was placed in a vacuum drying box at 90 °C for 12 hours to obtain a vanadium-based material.

[0040] Illuminate C 2 H 8 N 2 V 7 O 16 The mass ratio of the material, acetylene black, binder is 7:2:1 to weigh the raw material, after mixing, fully grind and mix well, and then add NMP (NMP and the mass ratio of the binder is 1:0.02326) to make the ground powder appear slurry, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com