A kind of Prussian blue composite silicon negative electrode material and preparation method thereof

A silicon-based anode material, Prussian blue technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problems of large volume change of Si-based materials, complex preparation methods, harsh preparation conditions, etc. , to achieve the effect of improving structural stability and electronic/ionic conductivity, improving electronic/ionic conductivity, and unique composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

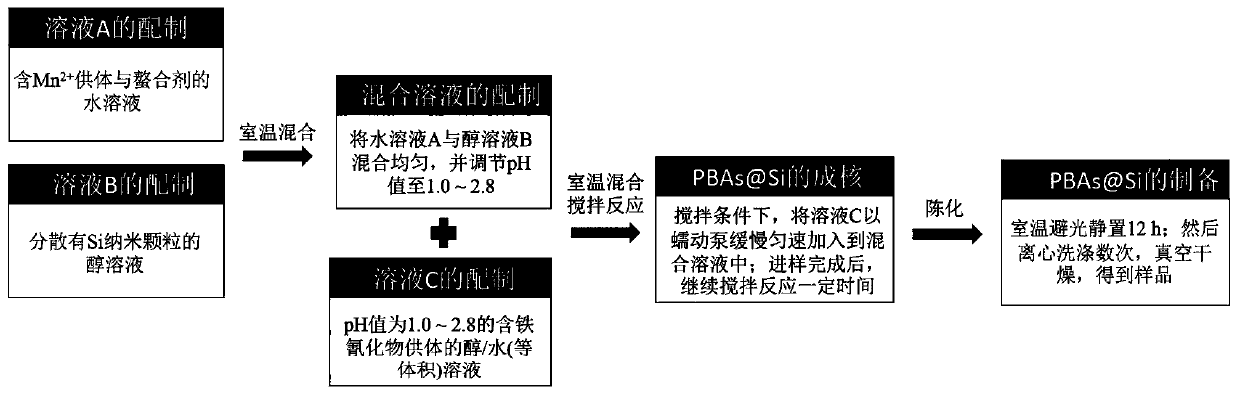

[0030] Production process such as figure 1 shown

[0031] Step 1. Weigh 0.845g of MnSO 4 -1H 2 Add O (0.05mol / L) and 3g of polyvinylpyrrolidone (PVP, Mw=10000Da) to 50ml of aqueous solution, stir at room temperature for 5min to obtain a transparent solution A; weigh 0.3g of silicon nanoparticles (30-50nm) Disperse in 100ml of absolute ethanol, ultrasonically disperse for 40min, so that the silicon nanoparticles are evenly dispersed in the alcohol solution to obtain solution B; weigh 1.614g of Na3 [Fe(CN) 6 ]-10H 2 O (0.03mol / L), was added into 50ml of aqueous solution, stirred at room temperature for 5min, and adjusted to pH 1.5 with HCl solution to obtain transparent solution C.

[0032] Step 2. At room temperature, mix solution A and solution B prepared in step 1 for 5 minutes under stirring at 600 rpm, and adjust the pH value of the solution to 1.5 with HCl to obtain a mixed solution;

[0033] Step 3. Add solution C dropwise to the mixed solution obtained in step 2 wit...

Embodiment 2

[0045] The following operating conditions of embodiment 1 are changed to: containing Mn 2+ The concentration of the donor solution A is 0.03mol / L, the chelating agent is sodium citrate, the pH value is 2.0, the injection time is 6h, and the stirring reaction time is 10min. Constitute the operating conditions of Example 2.

[0046] By the same test method as in Example 1, test the PBAs@Si core-shell nanocomposite particles prepared in Example 2, see Figure 9 , it can be clearly observed that the composite particles are cubic crystals, and the average size of the particles is 180nm, but the size dispersion needs to be improved.

[0047] By carrying out the electrochemical stability test on the PBAs@Si nanocomposite prepared in Example 2, refer to Figure 10 , the initial charge specific capacity of PBAs@Si nanocomposites is 1371.72mAh / g, which is due to the low Si content; after 50 cycles at a current density of 1A / g (1C), the capacity is maintained at 740.36mAh / g g, the cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com