A kind of preparation method of tungsten disulfide/carbon nanotube negative electrode composite material for sodium ion battery

A technology of carbon nanotubes and tungsten disulfide, which is applied in the field of sodium ion battery anode materials and its preparation, can solve the problems of reducing the cycle stability of electrode materials, low electronic/ion conductivity, and reducing rate performance, etc., and achieve high specific capacity , good repeatability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

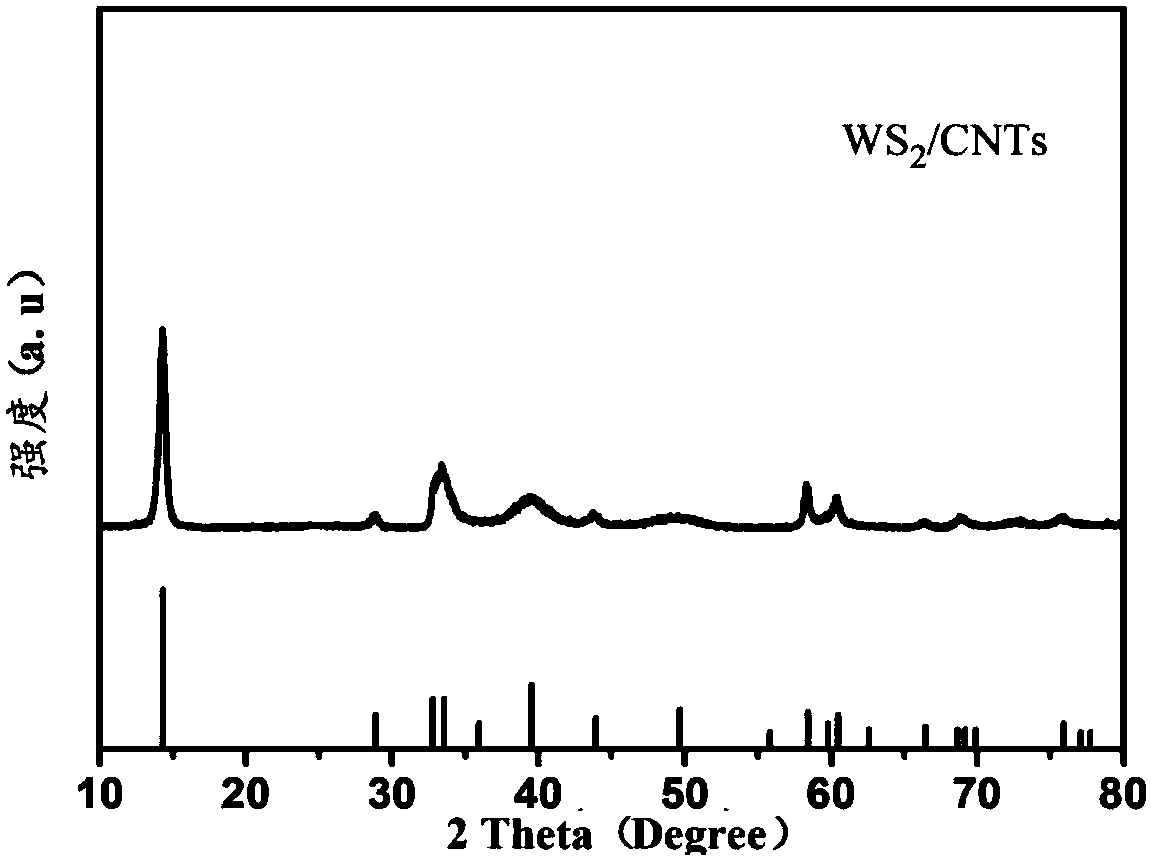

[0034]First, take 2g of ammonium phosphotungstate and place it in the upwind zone of the dual-temperature zone tube furnace, take 0.2g of carbon nanotubes and place it in the downwind zone, control the flow rate of the inert gas to 50 sccm, and the downwind zone will rise to 50°C at a rate of 10°C / min , when the temperature rises to the rated temperature, the upwind area rises to 900 °C at a rate of 10 °C / min, and the temperature is kept for 120 min. The product in the downwind area is the tungsten oxide / carbon nanotube composite material. Take 0.5g of tungsten oxide / carbon nanotube composite material and 2.5g of sulfur powder, add 200ml of octylamine-alcohol mixture with a volume ratio of 1:1, ultrasonicate for 5h, and then place it in a 60ml hydrothermal reaction kettle at 250℃ Undertake the hydrothermal reaction for 24 hours, and then the hydrothermal reaction product is suction filtered, washed, and vacuum-dried to obtain a high-purity tungsten disulfide / carbon nanotube com...

Embodiment 2

[0042] First, take 3g of ammonium phosphotungstate and place it in the upwind area of the dual temperature zone tube furnace, take 0.2g of carbon nanotubes and place it in the downwind area, control the flow rate of the inert gas to 50 sccm, and the downwind area will rise to 50°C at a rate of 10°C / min , when the temperature rises to the rated temperature, the upwind area rises to 900 °C at a rate of 10 °C / min, and the temperature is kept for 120 min. The product in the downwind area is the tungsten oxide / carbon nanotube composite material. Take 0.5g of tungsten oxide / carbon nanotube composite material and 4g of sulfur powder, add 200ml of octylamine-alcohol mixture with a volume ratio of 1:1, ultrasonicate for 5h, then place it in a 60ml hydrothermal reaction kettle, and heat it under the condition of 250℃. After thermal reaction for 24 hours, the hydrothermal reaction product was suction-filtered, washed, and vacuum-dried to obtain a high-purity tungsten disulfide / carbon na...

Embodiment 3

[0045] First, take 4g of ammonium phosphotungstate and place it in the upwind area of the dual temperature zone tube furnace, take 0.2g of carbon nanotubes and place it in the downwind area, control the flow rate of the inert gas to 50 sccm, and the downwind area will rise to 50°C at a rate of 10°C / min , when the temperature rises to the rated temperature, the upwind area rises to 900 °C at a rate of 10 °C / min, and the temperature is kept for 120 min. The product in the downwind area is the tungsten oxide / carbon nanotube composite material. Take 0.5g of tungsten oxide / carbon nanotube composite material and 5g of sulfur powder, add 200ml of octylamine-alcohol mixture with a volume ratio of 1:1, ultrasonicate for 5h, and then place it in a 60ml hydrothermal reaction kettle. After thermal reaction for 24 hours, the hydrothermal reaction product was suction-filtered, washed, and vacuum-dried to obtain a high-purity tungsten disulfide / carbon nanotube composite material. Take 0.5g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com