A kind of titanium nitride coated nickel titanate composite material and its preparation method and application

A composite material, nickel titanate technology, applied in the field of electrochemical energy storage, can solve the problems affecting the potential advantages of electrode materials, low electronic/ionic conductivity, etc., achieve broad industrial application prospects, improve electronic/ionic conductivity, improve Effect of rate performance and cycle stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

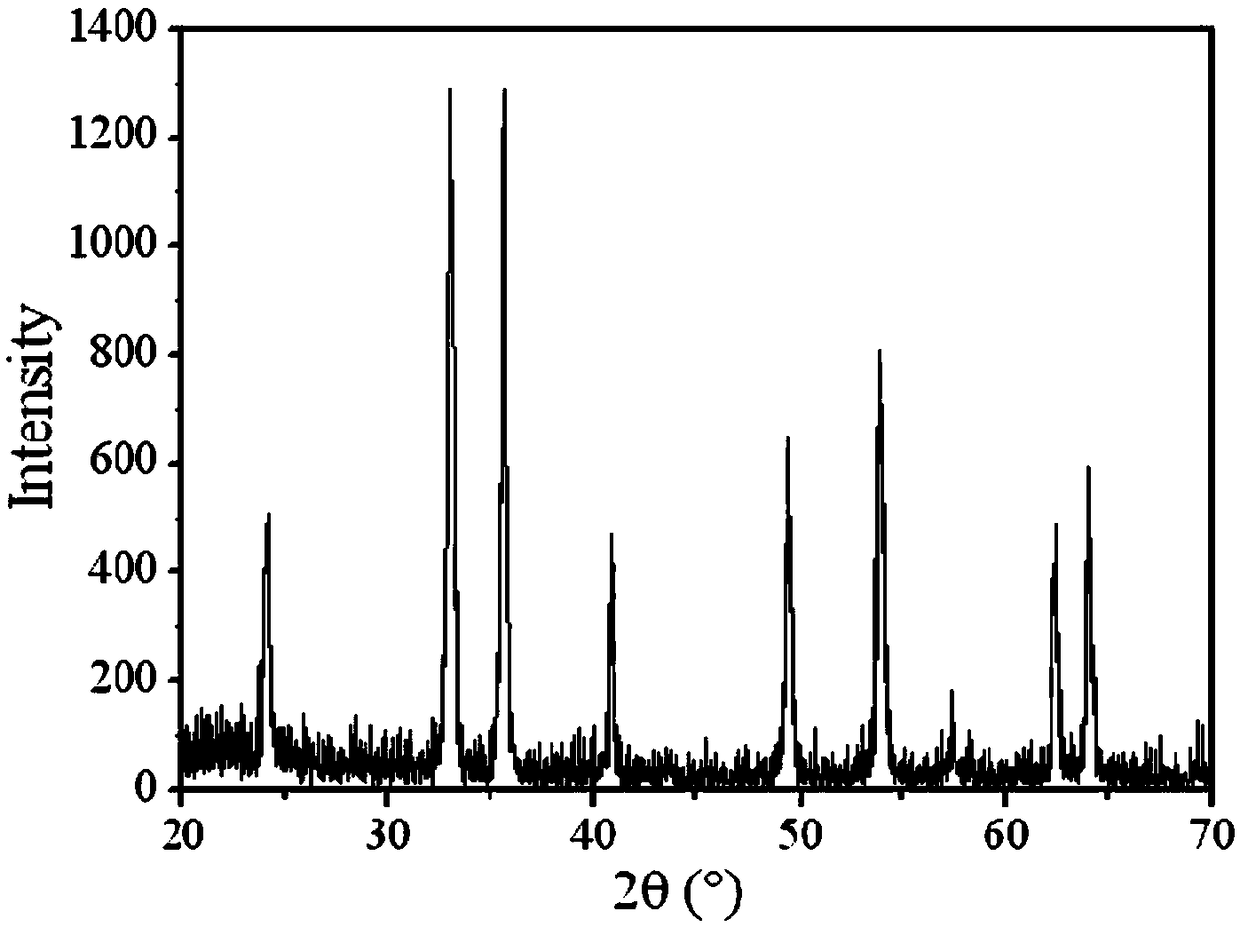

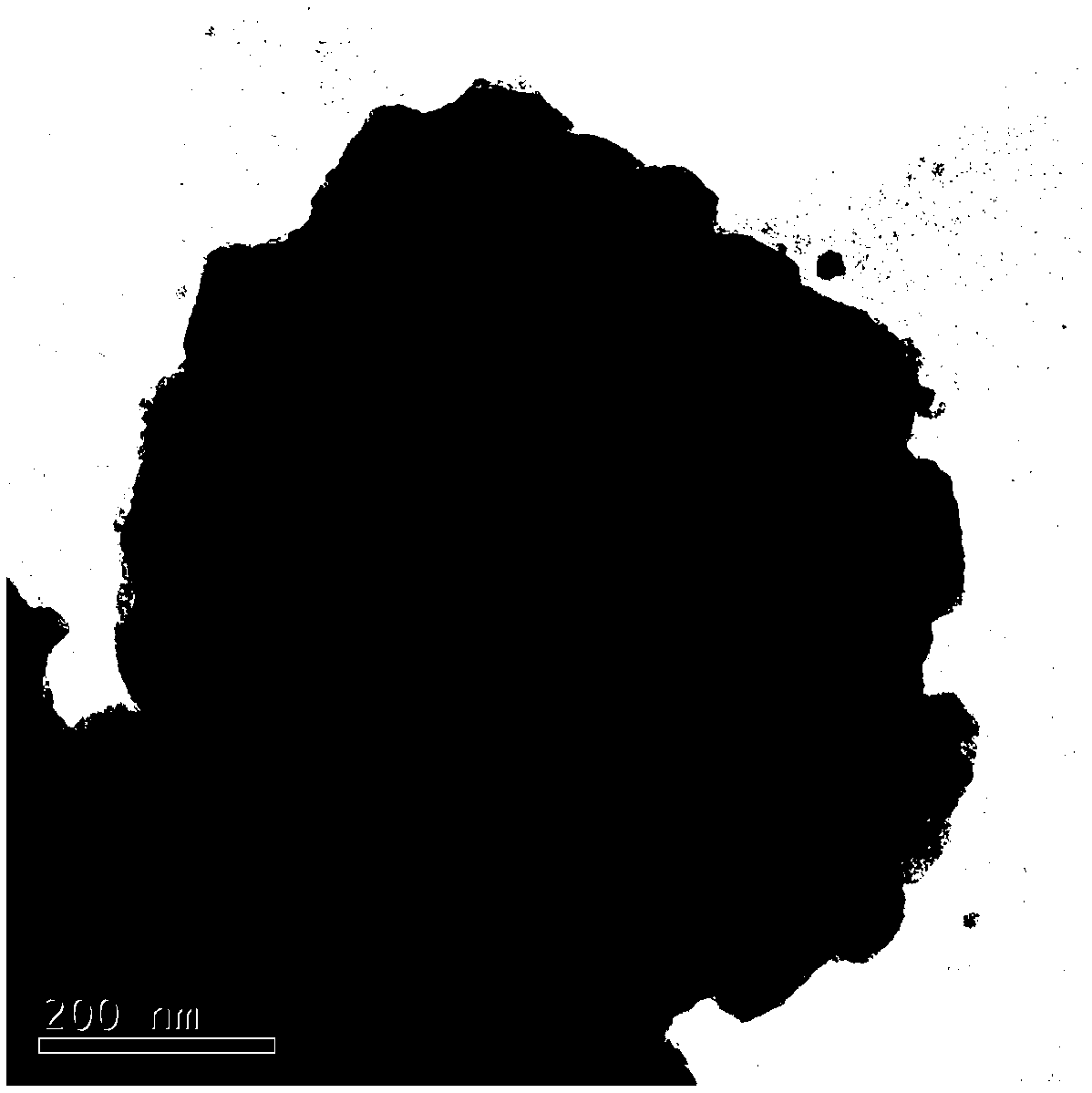

[0043] First, weigh 1.7g of tetrabutyl titanate and 1.45g of nickel nitrate hexahydrate to fully dissolve them in 200ml of ethylene glycol, then add 0.3g of citric acid to the above solution, and after stirring evenly, mix the solution Moved to a high-temperature reactor for solvothermal reaction at 180°C for 20h. The product obtained from the solvothermal reaction was repeatedly washed with water and ethanol, then suction-filtered, then placed at 80° C., and vacuum-dried for 10 hours to obtain spherical nickel titanate nanoparticles.

[0044] Then, take 0.2 g of the above-mentioned nickel titanate, add 1.5 g of tetrabutyl titanate solution, and mix the two evenly under ultrasonic conditions, then add 15 ml of deionized water dropwise to the solution, and after the two are evenly mixed, After standing, washing and drying, titanium dioxide coated nickel titanate composite material (TiO 2 @NiTiO 3 ).

[0045] Finally, take 0.2g of the above TiO 2 @NiTiO 3 Composite material...

Embodiment 2

[0053] First, weigh 1.7g of tetrabutyl titanate and 1.45g of nickel nitrate hexahydrate, and dissolve them fully in 200ml of glycerin solution, then add 0.3g of citric acid into the above solution, and after stirring evenly, mix the The solution was moved to a high-temperature reactor for solvothermal reaction at 180° C. for 20 h. The product obtained from the solvothermal reaction was repeatedly washed with water and ethanol, then suction-filtered, then placed at 80° C., and vacuum-dried for 10 hours to obtain spherical nickel titanate nanoparticles.

[0054] Then, take 0.2 g of the above-mentioned nickel titanate, add 1.5 g of tetrabutyl titanate solution, and mix the two evenly under ultrasonic conditions, then add 15 ml of deionized water dropwise to the solution, and after the two are evenly mixed, After standing, washing and drying, titanium dioxide coated nickel titanate composite material (TiO 2 @NiTiO 3 ).

[0055] Finally, take 0.2g of the above TiO 2 @NiTiO 3 C...

Embodiment 3

[0058] First, weigh 1.7g of tetrabutyl titanate and 1.45g of nickel nitrate hexahydrate, and dissolve them fully in 200ml of ethylene glycol solution, then add 0.2g of citric acid into the above solution, and after stirring evenly, mix the The solution was moved to a high-temperature reactor for solvothermal reaction at 180° C. for 20 h. The product obtained from the solvothermal reaction was repeatedly washed with water and ethanol, then suction-filtered, then placed at 80° C., and vacuum-dried for 10 hours to obtain spherical nickel titanate nanoparticles.

[0059] Then, take 0.2 g of the above-mentioned nickel titanate, add 1.5 g of tetrabutyl titanate solution, and mix the two evenly under ultrasonic conditions, then add 15 ml of deionized water dropwise to the solution, and after the two are evenly mixed, After standing, washing and drying, titanium dioxide coated nickel titanate composite material (TiO 2 @NiTiO 3 ).

[0060] Finally, take 0.2g of the above TiO 2 @NiT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com