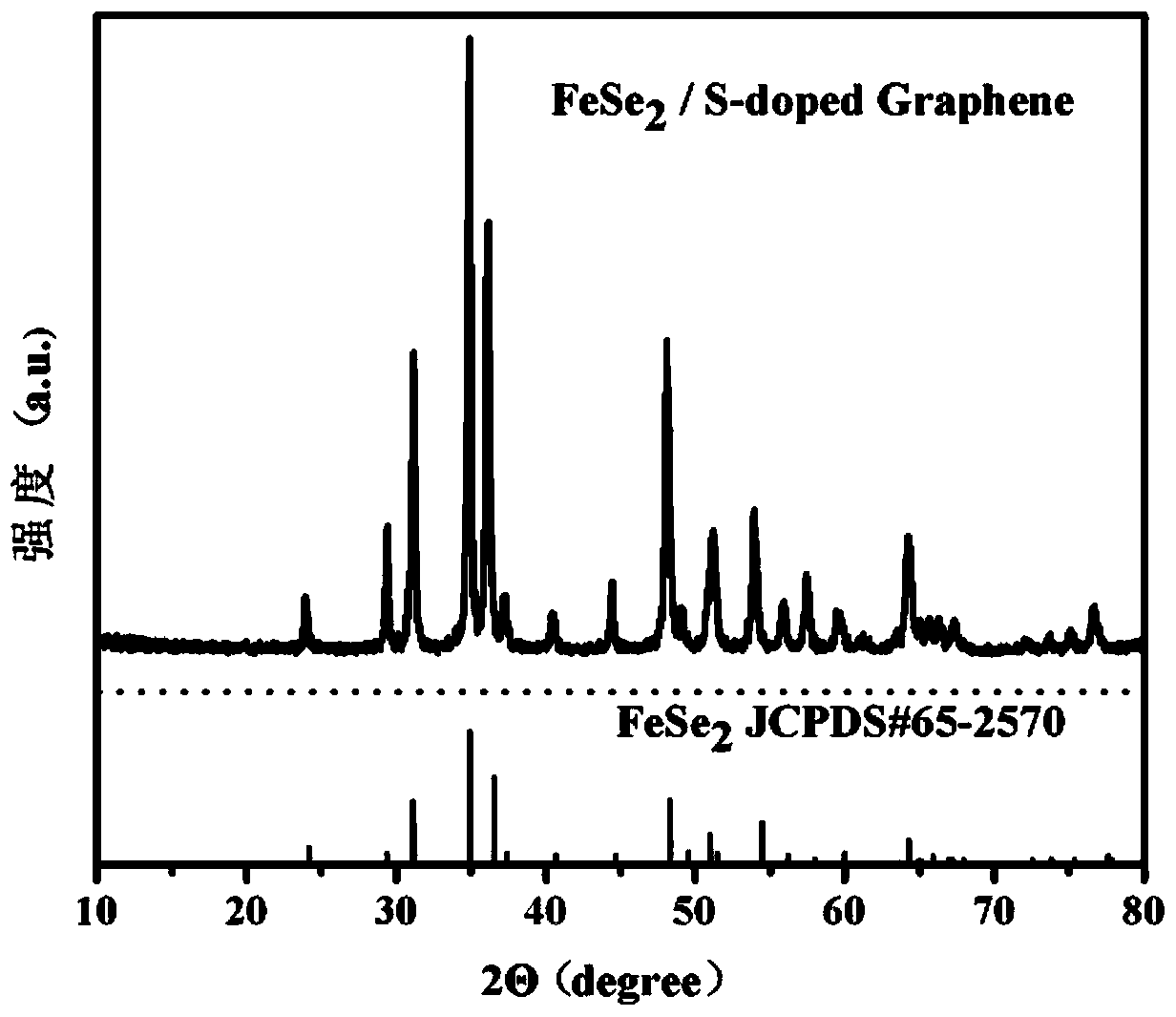

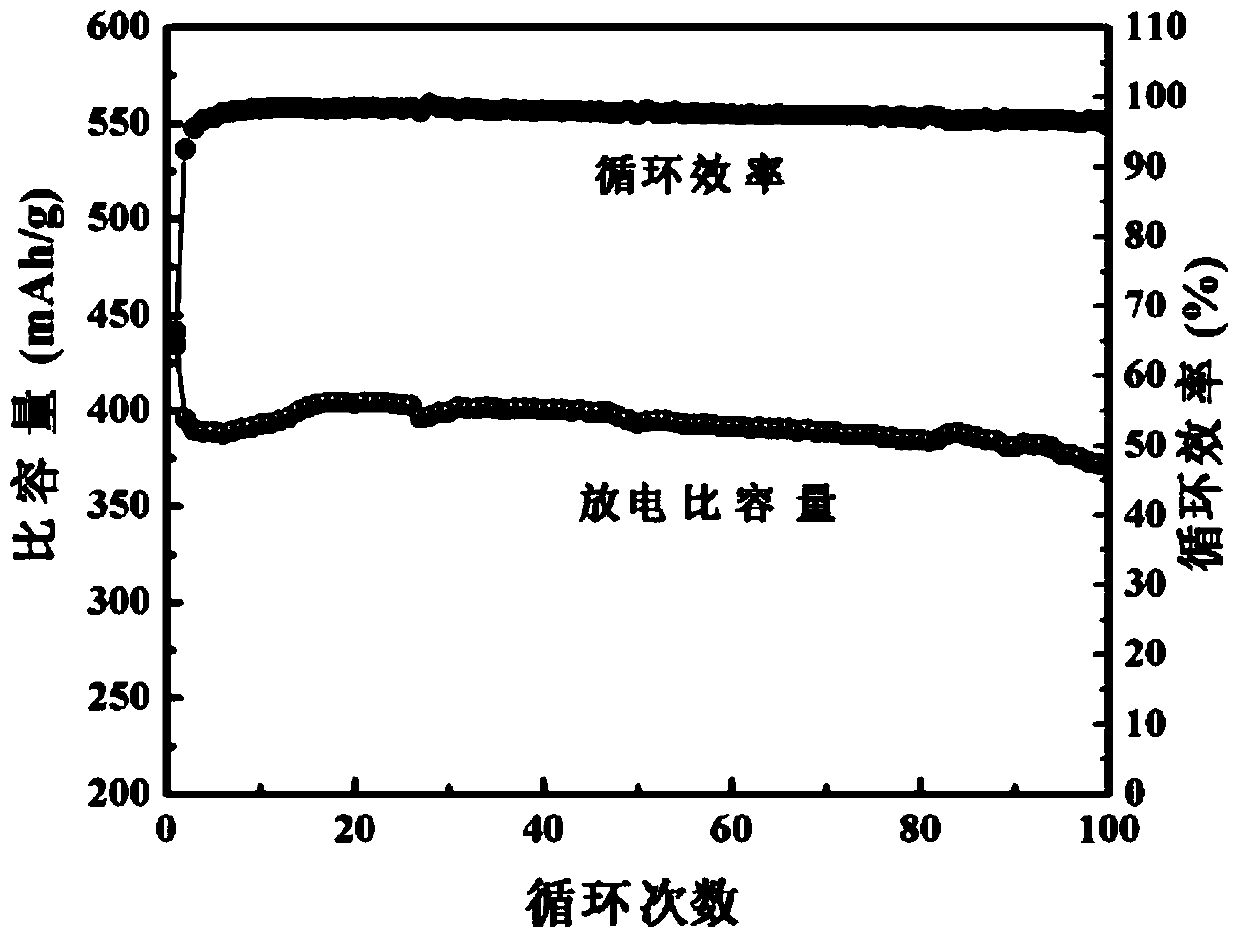

A kind of sodium ion battery iron diselenide/sulfur-doped graphene negative electrode composite material and preparation method thereof

A sulfur-doped graphene, sodium-ion battery technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., to achieve high discharge specific capacity, improve rate performance and cycle stability, and reduce volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] First take by weighing 3g of flaky graphite with a purity of 99.5%, join in the mixed solution containing 350mL mass fraction of concentrated sulfuric acid of 98% and 50mL of mass fraction of phosphoric acid of 85%, add 18g of potassium permanganate in batches for oxidation, and The mixed solution was kept at 0°C under ice bath and stirred for 2h, then heated to 45°C in a water bath and reacted under magnetic stirring for 12h to obtain a mixed solution; then, 400mL of deionized water was slowly added to the mixture under ice bath After the reaction is stable, slowly add 20ml of hydrogen peroxide to remove unreacted potassium permanganate, and then the color of the mixed solution turns bright yellow; finally, the resulting mixed solution is repeatedly washed with a large amount of deionized water, centrifuged and put into a dialysis bag for dialysis A pure graphene oxide solution can be obtained in 5-7 days. The concentration of graphene oxide in the prepared graphene ox...

Embodiment 2

[0055] Measure 56ml of the above-mentioned graphene oxide solution (graphene oxide content is 56×7.5mg / ml=420mg=0.42g) with a graduated cylinder, pour it into a 500ml beaker and stir it magnetically at room temperature. Then weigh 0.42 g of thioacetamide according to the mass ratio of sulfur source and graphene oxide 1:1, add in batches to the graphene oxide solution being stirred, and continue stirring after the thioacetamide and graphene oxide solution are fully mixed After 15 hours, a sulfur-containing graphene oxide solution can be obtained.

[0056] According to the molar ratio of selenium source and iron source is 2:1, and the molar ratio of iron source and citric acid (CA) is 1:5, respectively weigh ferrous ammonium sulfate hexahydrate 2.352g, selenium dioxide 1.332g, citric acid (CA) ) 6g, and successively added to 100ml deionized water, after ultrasonic 0.5h dispersed evenly, slowly added the mixed solution into the above-mentioned sulfur-containing graphene oxide sol...

Embodiment 3

[0059] Measure 56ml of the above-mentioned graphene oxide solution (graphene oxide content is 56×7.5mg / ml=420mg=0.42g) with a graduated cylinder, pour it into a 500ml beaker and stir it magnetically at room temperature. Then weigh 0.42 g of thioacetamide according to the mass ratio of sulfur source and graphene oxide 1:1, add in batches to the graphene oxide solution being stirred, and continue stirring after the thioacetamide and graphene oxide solution are fully mixed After 15 hours, a sulfur-containing graphene oxide solution can be obtained.

[0060] According to the molar ratio of selenium source and iron source is 2:1, and the molar ratio of iron source and citric acid (CA) is 1:15, respectively weigh ferrous ammonium sulfate hexahydrate 2.352g, selenium dioxide 1.332g, citric acid (CA) ) 18g, and successively added to 100ml deionized water, after ultrasonic 0.5h dispersed uniformly, slowly added the mixed solution into the above-mentioned sulfur-containing graphene oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com