Ardealite pretreatment method and application thereof

A phosphogypsum and pretreatment technology, applied in the field of building materials, can solve the problems of low degree of resource utilization of phosphogypsum, poor product performance, poor mechanical properties, etc., and achieves easy control of setting time, large-scale treatment, and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Phosphogypsum pretreatment:

[0060] 10,000 grams of bulk phosphogypsum is screened out through a 70-mesh sieve; the obtained phosphogypsum is placed in a ball mill (Wuxi Jianyi Instrument Machinery Co., Ltd., SM-500TEST MILL) for grinding, and ground to 70-90 mesh; The ground phosphogypsum is irradiated in a microwave field (Guangzhou Wancheng Microwave Equipment Co., Ltd., CNWB), microwave technical parameters: 2.45GHz, power 560W in a microwave field, heating rate 70°C / min, time 5min; Calcining the phosphogypsum after microwave irradiation at 150° C. for 70 minutes; aging the calcined phosphogypsum in an environment with a humidity RH of 0-30%, when the crystal water content of the obtained gypsum is 4.5-5% by weight, type AIII When the content of the anhydrite is 1-3% by weight, the aging treatment is stopped; the pH value of the phosphogypsum after the aging treatment is tested to be 5.6.

[0061] Preparation of phosphogypsum plasterboard:

[0062] Weigh 1000g of...

Embodiment 2

[0076] The pretreatment process of phosphogypsum is the same as that in Example 1, and the treated phosphogypsum is used to prepare self-leveling floor mortar.

[0077] 100 parts by weight of pretreated phosphogypsum, 15 parts by weight of 40-70 mesh fine river sand, 15 parts by weight of 70-140 mesh fine river sand, 8 parts by weight of cement, polycarboxylate water reducer 0.2 parts by weight, efficient gypsum base retarder Retardan P 0.03 parts by weight, 2 parts by weight of 5010N and 0.03 parts by weight of stabilizer Starvis 3040F were mixed evenly to obtain phosphogypsum self-leveling mortar, which was then mixed with 24 parts by weight of water to obtain phosphogypsum self-leveling slurry.

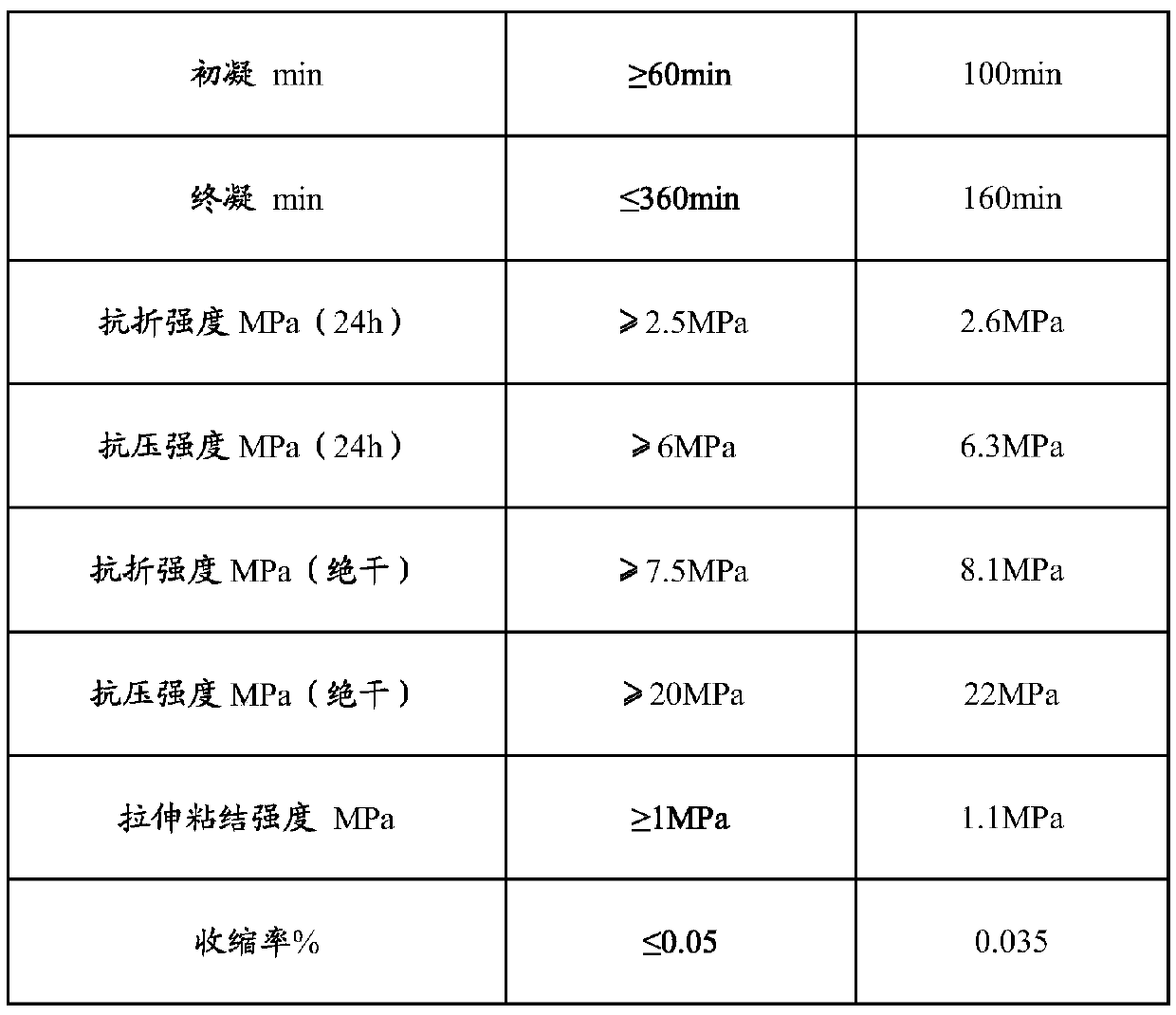

[0078] The performance test was carried out according to the industry standard JC / T 1023-2007 "Gypsum-based self-leveling mortar", and the results are shown in Table 2.

[0079] Table 2 Performance of phosphogypsum self-leveling floor mortar

[0080]

[0081]

[0082] It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com