A kind of ceramic film and preparation method thereof

A technology of ceramic membrane and particle suspension, which is applied in the field of membrane materials, can solve the problems of insufficient wear resistance and high brittleness, and achieve the effects of good integrity, low permeability resistance, and continuous and uniform membrane layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

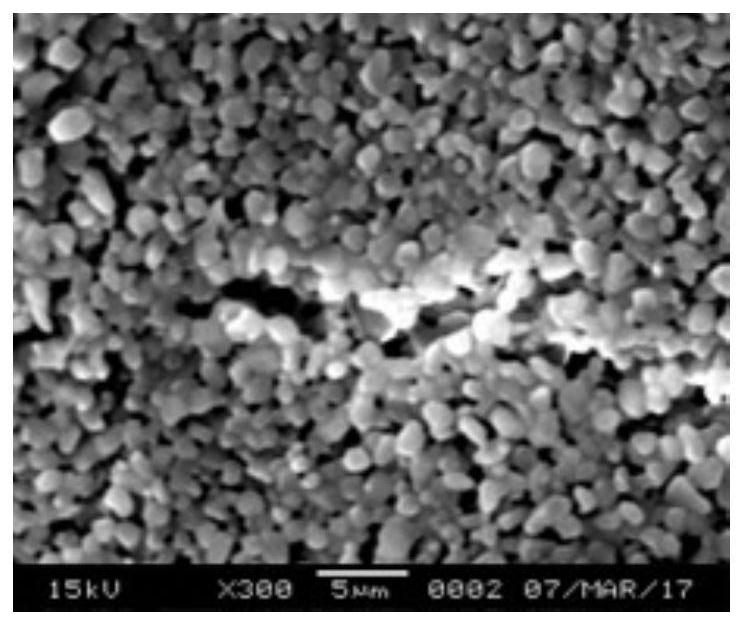

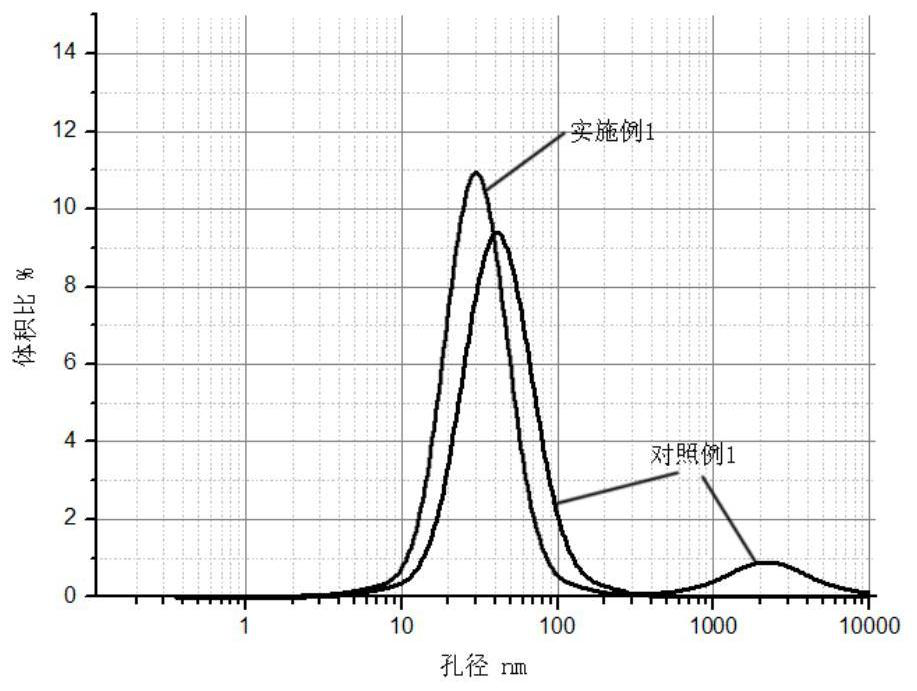

Image

Examples

Embodiment 1

[0050] Preparation of mixed sols:

[0051] The nitrates of aluminum, zirconium, and yttrium were prepared as mixed sols according to the combination of aluminum nitrate + zirconium nitrate, yttrium nitrate + zirconium nitrate, and the mass ratio of aluminum to zirconium oxide was (4:1) (referring to the sol in the two sols zirconium oxide weight), the mass fraction of yttrium oxide is 4% of the zirconium oxide weight (referring to the zirconium oxide weight sum in the two sols) for the preparation of raw materials, the first sol is aluminum Zirconium sol, the second sol is yttrium-zirconium sol, which is hydrolyzed into sols with ammonia water respectively, and then mixed. The temperature of the hydrolysis process is controlled at 60 ° C, and the pH is controlled during the dripping of ammonia water to 9;

[0052] Preparation of sol of composite nanopowder:

[0053] After obtaining the mixed sol, adding the alumina powder with an average particle diameter of 200nm and the tit...

Embodiment 2

[0055] Preparation of mixed sols:

[0056] The nitrates of aluminum, zirconium, and cerium were prepared as mixed sols according to the combination of aluminum nitrate + zirconium nitrate, yttrium nitrate + zirconium nitrate, and the mass ratio of aluminum to zirconium oxide was (3:1) (referring to the sol in the two sols zirconium oxide weight), the mass fraction of yttrium oxide is 5% of the zirconium oxide weight (referring to the zirconium oxide weight sum in the two sols) for the preparation of raw materials, the first sol is aluminum Zirconium sol, the second sol is yttrium-zirconium sol, which is hydrolyzed into sols with ammonia water respectively, and then mixed. The temperature of the hydrolysis process is controlled at 60 ° C, and the pH is controlled during the dripping of ammonia water to 9.5;

[0057] Preparation of sol of composite nanopowder:

[0058] After obtaining the mixed sol, add alumina powder with an average particle size of 100nm and titanium oxide po...

Embodiment 3

[0060] Preparation of mixed sols:

[0061] The nitrates of aluminum, zirconium, and cerium were prepared as mixed sols according to the combination of aluminum nitrate + zirconium nitrate, yttrium nitrate + zirconium nitrate, and the mass ratio of aluminum to zirconium oxide was (1:1) (referring to the sol in the two sols zirconium oxide weight), the mass fraction of yttrium oxide is 6% of the zirconium oxide weight (referring to the zirconium oxide weight sum in the two sols) for the preparation of raw materials, the first sol is aluminum Zirconium sol, the second sol is yttrium-zirconium sol, which is hydrolyzed into sols with ammonia water respectively, and then mixed. The temperature of the hydrolysis process is controlled at 60 ° C, and the pH is controlled during the dripping of ammonia water to 9.5;

[0062] Preparation of sol of composite nanopowder:

[0063] After obtaining the mixed sol, add alumina powder with an average particle size of 100nm and titanium oxide po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com