Polyaniline-based ammonia gas sensor with moisture resistance and productionmethod thereof

An ammonia gas sensor, polyaniline-based technology, applied in instruments, material resistance, scientific instruments, etc., to achieve the effects of small size, strong practicability and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

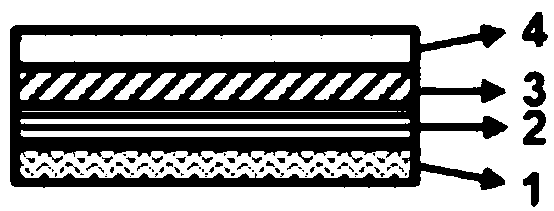

[0034] This embodiment provides a polyaniline-based ammonia sensor with moisture resistance, including a substrate 1, an interdigital electrode 2, a hygroscopic film 3 arranged on the surface of the interdigital electrode 2, and a hygroscopic film formed on the surface of the hygroscopic film 3. Polyaniline film4.

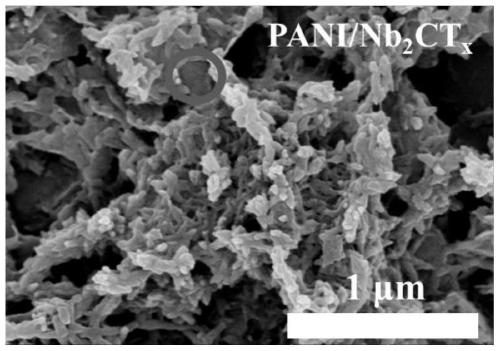

[0035] Wherein, the hygroscopic film 3 is a material with hygroscopic properties and a large specific surface area, and the hygroscopic film 3 is selected from MXene materials, graphene oxide or two-dimensional transition metal sulfides.

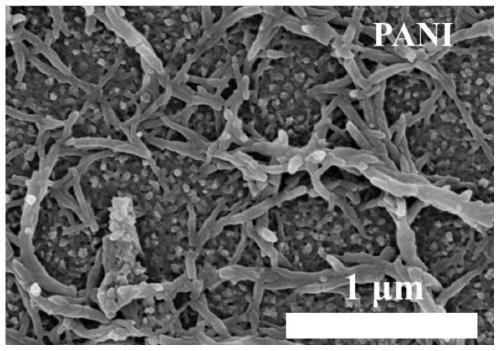

[0036] The polyaniline film 4 is formed by polymerizing on the surface of the hygroscopic film 3 by means of chemical oxidation polymerization. The polyaniline film 4 itself has porosity, and the size and density of the grids in its spatial grid structure can be controlled by adjusting polymerization parameters (such as temperature, concentration, etc.).

[0037] The substrate 1 is selected from polyimide film (PI), polyethylene...

Embodiment 2

[0040] This embodiment provides a method for preparing a polyaniline-based ammonia gas sensor with moisture resistance, comprising the following steps:

[0041] (1) Cut the flexible PI substrate into a suitable size, wash it with deionized water, acetone, ethanol, and deionized water, dry it naturally, and prepare gold interdigitated electrodes on the surface of the substrate by thermal evaporation.

[0042] (2) Niobium carbide (Nb 2 CT x ) film, wherein the preparation process of the niobium carbide dispersion is as follows: 1g carbon aluminum niobium (Nb 2 AlC) is added in the hydrofluoric acid solution of 40wt%, then ultrasonic 48h in the water-bath environment of 50 ℃, after the deionized water washes, the precipitate is soaked in 25wt% tetrapropylammonium hydroxide (TPAOH) for 72h, finally After washing and drying with deionized water, it was dispersed in N-methylpyrrolidone (NMP) solvent.

[0043] (3) Soak the devices prepared in process (2) in 1% polydiallyldimethyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com