Aluminum oxide and preparation method and application thereof

An alumina and peroxide technology, which is applied in the preparation of alumina/hydroxide, chemical instruments and methods, alumina/aluminum hydroxide, etc., can solve the problem of low specific surface area, small pore size and pore volume of synthetic alumina, etc. problem, to achieve the effect of complete crystal, low surface energy and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

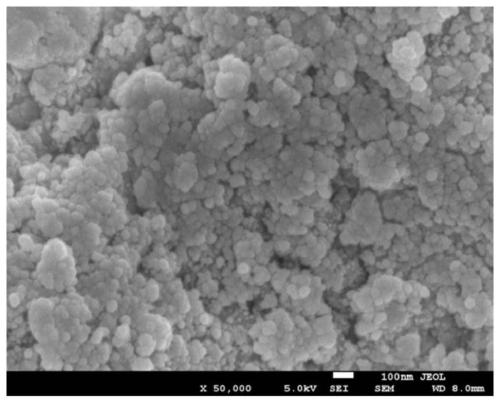

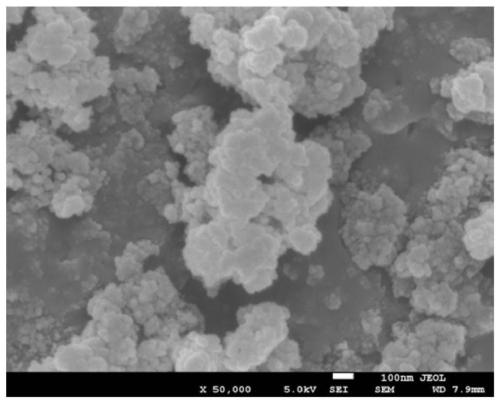

Image

Examples

Embodiment 1

[0106] The present embodiment prepares alumina according to the following method:

[0107] (1) Add 100g of ethylene glycol, 10g of aluminum powder and 0.1g of aluminum chloride into the autoclave, turn on the stirrer and control the rotation speed to 500r / min, the reaction temperature is 95°C, and the reaction is carried out at a pressure of 1.5MPa for 1.5 hours, then Filter through a 1000-mesh filter at 95°C to obtain an aluminum alkoxide solution, in which about 210 g of aluminum ethylene glycol is obtained;

[0108] (2) Add the above-mentioned aluminum alkoxide solution into the autoclave, add 500g of ethylene glycol, raise the temperature to a reaction temperature of 95°C, then add 40g of deionized water into the autoclave, stir while adding it dropwise, and dissolve the deionized water in 15 minutes. After the water is added dropwise, vacuumize to evaporate all the water, age at 120°C for 12 hours, and finally filter and dry to obtain 80g of pseudoboehmite containing 75% ...

Embodiment 2

[0112] The present embodiment prepares alumina according to the following method:

[0113] (1) Add 250g of trimethylolpropane, 20g of aluminum powder and 1.0g of aluminum chloride into the autoclave, turn on the stirrer and control the rotation speed to 1000r / min, the reaction temperature is 100°C, and the reaction is carried out at a pressure of 2.0MPa for 2 hours. , and then filtered at 100°C with a 600-mesh filter to obtain an aluminum alcohol solution, in which about 498g of aluminum methylol propane;

[0114] (2) Add the above-mentioned aluminum alkoxide solution into the autoclave, add 700g of trimethylolpropane, heat up to the reaction temperature of 100°C, then add 100g of deionized water into the reaction kettle, stir while adding it dropwise, and put the After the addition of deionized water was completed, all the water was evaporated by vacuuming, aged at 150°C for 36 hours, and finally filtered and dried to obtain 200g of pseudoboehmite containing 80% trimethylolpr...

Embodiment 3

[0118] The present embodiment prepares alumina according to the following method:

[0119] (1) Add 200g of dipropylene glycol, 15g of aluminum powder and 1.5g of mercuric iodide into the autoclave, turn on the stirrer and control the rotating speed to be 1200r / min, the reaction temperature is 200°C, and the reaction is carried out under a pressure of 5.0MPa for 1 hour, Then, at 150° C., a 1200-mesh filter screen was used to filter to obtain an aluminum alcohol solution, wherein aluminum dipropylene glycol was 395 g;

[0120] (2) Add the above-mentioned aluminum alcohol solution into the autoclave, add 500g of dipropylene glycol, heat up to the reaction temperature of 95°C, then add 150g of deionized water into the reaction kettle, stir while adding it dropwise, and remove the deionized water in 60 minutes. After the ionic water was added dropwise, all the water was evaporated under vacuum, aged at 200°C for 24 hours, and finally filtered and dried to obtain 180g of pseudo-boeh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com