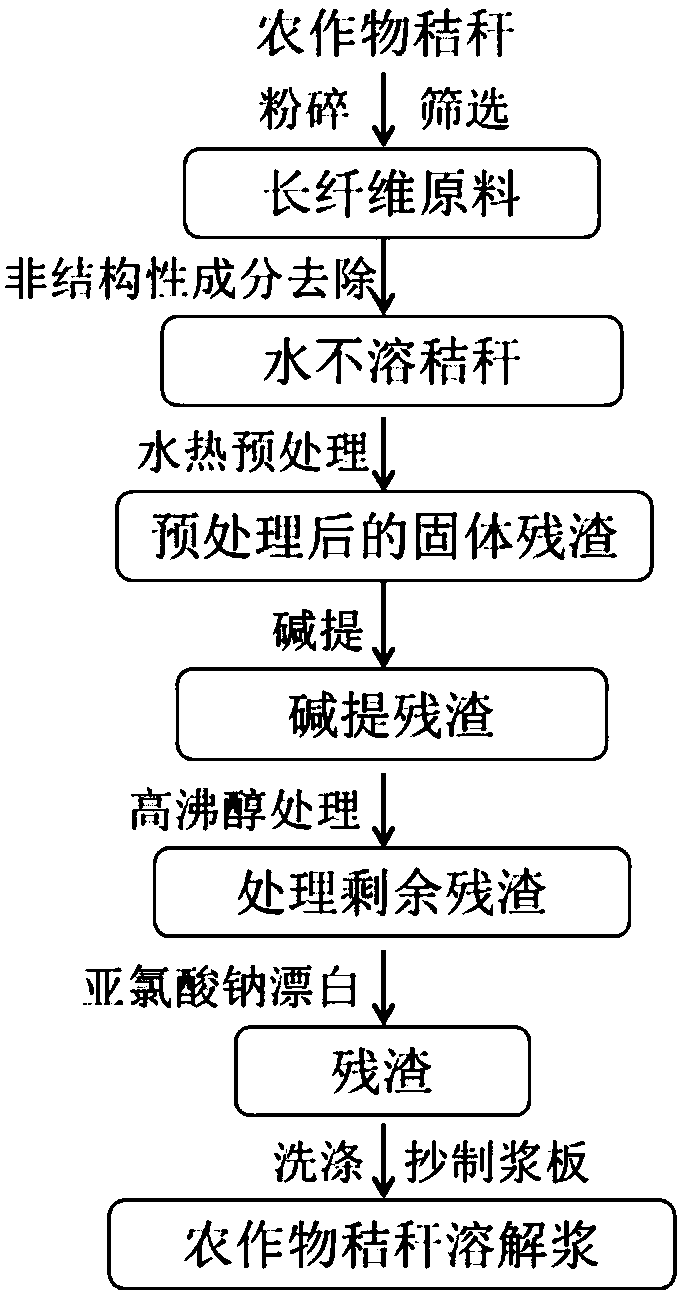

Method for preparing high-quality crop straw dissolved pulp through hydrothermal pretreatment

A technology for crop straw and pretreatment, which is applied in the directions of pulping with inorganic alkalis, pulp bleaching, raw material separation, etc., can solve the problems of economic benefits to be improved, waste of resources, economic benefits, cost reduction, etc., so as to improve the comprehensive utilization efficiency and production efficiency. Process practicability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The corn stalks were air-dried, crushed, and sieved to screen out the long fiber part with a particle size of 3-5 cm; the screened long fiber stalks were mixed with hot water at a solid-to-liquid ratio of 1:15 (g / mL), soaked for 1 h, and The non-structural components in the straw were removed to obtain water-insoluble straw; then the water-insoluble straw and water were placed in a hydrothermal reactor at a solid-to-liquid ratio of 1:5, heated to 150°C, and treated for 1 hour; after hydrothermal pretreatment, the Straw and 5% (w / v) sodium hydroxide solution according to the solid-to-liquid ratio of 1:5, heated to 50°C, and extracted for 1 hour; the alkali-treated straw and 50% (w / v) 1,4-Butanediol was heated to 100°C at a solid-to-liquid ratio of 1:5, and reacted for 1 hour; the above raw materials were mixed with 1% (w / v) sodium chlorite acidic solution (adjusted to pH=3.6 with acetic acid) According to the solid-to-liquid ratio of 1:10, heat to 50°C and bleach for 1 h...

Embodiment 2

[0023] The corn stalks were air-dried, crushed, and sieved to screen out the long fiber part with a particle size of 3-5 cm; the screened long fiber stalks were mixed with hot water at a solid-to-liquid ratio of 1:15 (g / mL), soaked for 1 h, and Remove the non-structural components in the straw to obtain water-insoluble straw; then place the water-insoluble straw and water in a hydrothermal reactor at a solid-to-liquid ratio of 1:15, heat to 200°C, and treat for 0.5h; after hydrothermal pretreatment The straw with a mass fraction of 10% (w / v) sodium hydroxide solution was heated to 90°C at a solid-to-liquid ratio of 1:10, and extracted for 2 hours; the straw after alkali treatment was mixed with a mass fraction of 60% (w / v ) 1,4-butanediol according to the solid-to-liquid ratio of 1:15, heated to 150°C, and reacted for 1 hour; the above raw materials were mixed with a mass fraction of 6% (w / v) sodium chlorite acidic solution (adjusted with acetic acid to pH=3.7 ) at a solid-to-...

Embodiment 3

[0025] The corn stalks were air-dried, crushed, and sieved to screen out the long fiber part with a particle size of 3-5 cm; the screened long fiber stalks were mixed with hot water at a solid-to-liquid ratio of 1:15 (g / mL), soaked for 1 h, and The non-structural components in the straw were removed to obtain water-insoluble straw; then the water-insoluble straw and water were placed in a hydrothermal reactor at a solid-to-liquid ratio of 1:20, heated to 230°C, and treated for 2 hours; after hydrothermal pretreatment, The straw and the mass fraction of 10% (w / v) sodium hydroxide solution according to the solid-to-liquid ratio of 1:20, heated to 90 ° C, extracted for 2 hours; 1,4-Butanediol was heated to 200°C at a solid-to-liquid ratio of 1:20, and reacted for 2 hours; the above raw materials were mixed with 6% (w / v) sodium chlorite acidic solution (adjusted pH=3.8 with acetic acid) According to the solid-to-liquid ratio of 1:20, heat to 80°C, and bleach for 2 hours; the bleac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com