Low-cost chromium-containing Q460MC steel plate and production method thereof

A production method and low-cost technology, applied in the field of steel rolling, can solve problems such as unfavorable green development and increased production costs, and achieve the effects of reducing production costs, improving weldability, and improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

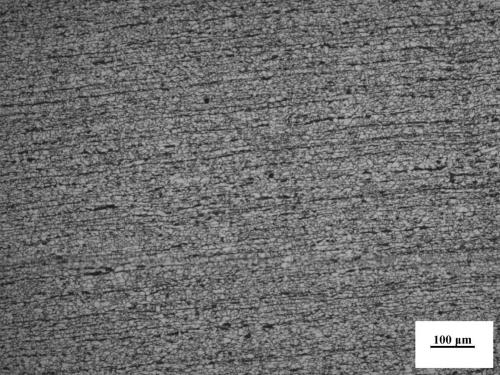

Embodiment 1

[0053] A low-cost chromium-containing Q460MC steel plate, the chemical composition and weight percentage of each component are: C: 0.08%-0.11%, Si: 0.10%-0.20%, Mn: 1.30%-1.60%, P: ≤0.020 %, S: ≤0.005%, Als: 0.015%~0.035%, Nb: 0.030%~0.040%, Cr: 0.15%~0.25%, Ti: 0.010%~0.020%, and the rest are Fe and unavoidable impurities;

[0054] In step A, the slag thickness is 42mm, the oxygen concentration in the converter is 363ppm, and the tapping time is 4min;

[0055] In step B, the retention time of white slag is 16 minutes, and the time of soft argon blowing is 9 minutes;

[0056] In step D, the temperature in the heating section is 1200°C, the temperature in the soaking section is 1130°C, and the heating time is 3.5h;

[0057] In step E, the rough rolling start temperature is 1050°C, the rough rolling finish temperature is 965°C, the rolling pass is 10 passes, the rough rolling final pass pressure ratio is 21%, and the minimum intermediate billet thickness is 50mm;

[0058] In s...

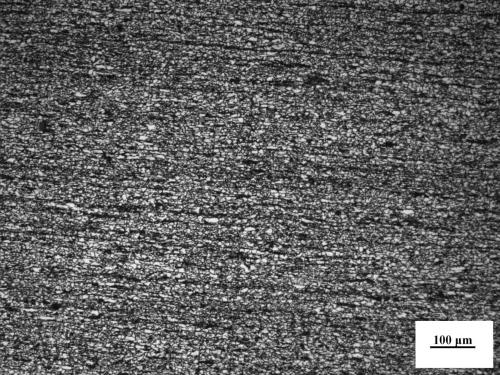

Embodiment 2

[0068] A low-cost chromium-containing Q460MC steel plate, the chemical composition and weight percentage of each component are: C: 0.08%-0.11%, Si: 0.10%-0.20%, Mn: 1.30%-1.60%, P: ≤0.020 %, S: ≤0.005%, Als: 0.015%~0.035%, Nb: 0.030%~0.040%, Cr: 0.15%~0.25%, Ti: 0.010%~0.020%, and the rest are Fe and unavoidable impurities;

[0069] In step A, the slag thickness is 40mm, the oxygen concentration in the converter is 457ppm, and the tapping time is 4min;

[0070] In step B, the retention time of white slag is 18 minutes, and the time of soft argon blowing is 9 minutes;

[0071] In step D, the temperature in the heating section is 1250°C, the temperature in the soaking section is 1180°C, and the heating time is 3.0h;

[0072] In step E, the starting temperature of rough rolling is 1075°C, the finishing temperature of rough rolling is 985°C, the rolling pass is 10 passes, the pressure ratio of the final pass of rough rolling is 20%, and the minimum thickness of the intermediate b...

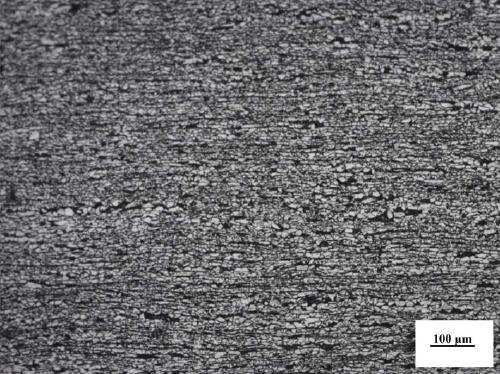

Embodiment 3

[0083] A low-cost chromium-containing Q460MC steel plate, the chemical composition and weight percentage of each component are: C: 0.08%-0.11%, Si: 0.10%-0.20%, Mn: 1.30%-1.60%, P: ≤0.020 %, S: ≤0.005%, Als: 0.015%~0.035%, Nb: 0.030%~0.040%, Cr: 0.15%~0.25%, Ti: 0.010%~0.020%, and the rest are Fe and unavoidable impurities;

[0084] In step A, the slag thickness is 40mm, the oxygen concentration in the converter is 423ppm, and the tapping time is 4min;

[0085] In step B, the retention time of white slag is 16 minutes, and the time of soft argon blowing is 10 minutes;

[0086] In step D, the temperature in the heating section is 1250°C, the temperature in the soaking section is 1160°C, and the heating time is 3.2h;

[0087] In step E, the rough rolling start temperature is 1100°C, the rough rolling finish temperature is 990°C, the rolling pass is 8 passes, the rough rolling final pass pressure ratio is 24%, and the minimum intermediate billet thickness is 80mm;

[0088] In s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com