Recyclable carbon quantum dot nano lubricating oil additive and preparation method thereof

A technology of lubricating oil additives and carbon quantum dots, applied in the directions of additives, chemical recovery, lubricating compositions, etc., can solve problems such as unreported, achieve the effects of improving dispersibility, being beneficial to large-scale production, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

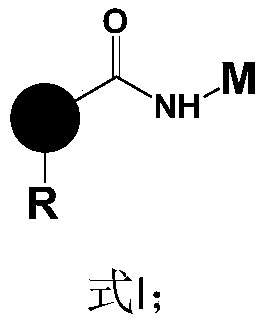

[0054] In a specific embodiment, the preparation method of the additive comprises the following steps:

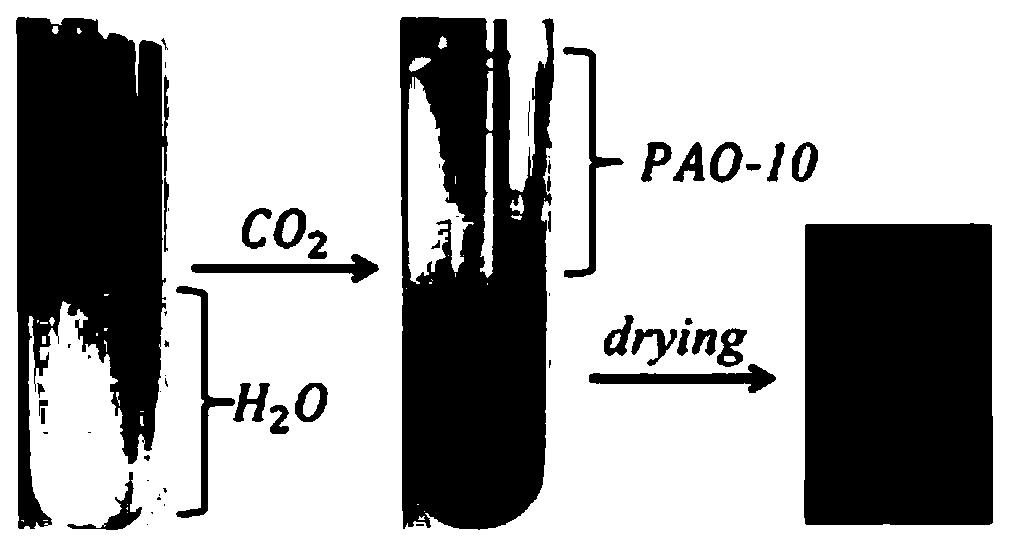

[0055] a. Combine the carbon source with CO 2 The responsive amine and the reaction medium are uniformly mixed to obtain a mixture;

[0056] b. Reflux the mixture at 180-240°C, preferably 220°C, for 2-6 hours, preferably 2-4 hours, to obtain a black dispersion;

[0057] c. Distilling the black dispersion under reduced pressure, removing the reaction medium to obtain a black jelly, washing and drying the black jelly to obtain the target product;

[0058] The carbon source is preferably one or more of citric acid monohydrate, ascorbic acid, and gluconic acid;

[0059] The CO 2 Responsive amines are preferably 2-amino-5-diethylaminopentane, 3-(dibutylamino)propylamine, 1,4-bis(3-aminopropyl)piperazine, (s)-2-(ammonia At least one of methyl)-1-ethylpyrrolidine and N,N-diisopropylethylenediamine; the reaction medium is one of n-hexanol, n-heptanol and n-octanol, preferably ...

Embodiment 1

[0086] A preparation method of recyclable carbon quantum dot nano lubricating oil additive, specifically comprising the following steps:

[0087] (1) Under oil bath conditions, 0.02M C 6 h 8 o 7 ·H 2 O and 0.07M 2-amino-5-diethylaminopentane are mixed, and the molar ratio is 1:3.5, then add 15ml n-octanol, stir and make it mix uniformly, wherein C 6 h 8 o 7 ·H 2 O is a carbon source, and n-octanol is a reaction medium;

[0088] (2) Transfer the mixed solution in step (1) to a 100ml three-necked flask, and reflux for 4h under magnetic stirring and nitrogen protection to obtain a black dispersion. Among them, the nitrogen gas flow rate is 10 -3 m 3 / min, the magnetic stirring rate is 120rpm / min, and the reaction temperature is 220°C.

[0089] (3) carry out decompression distillation to black dispersion liquid in step (2), after removing the n-octanol as reaction medium, obtain black colloid;

[0090] (4) Under the assistance of ultrasound, wash the black jelly in step...

Embodiment 2-5

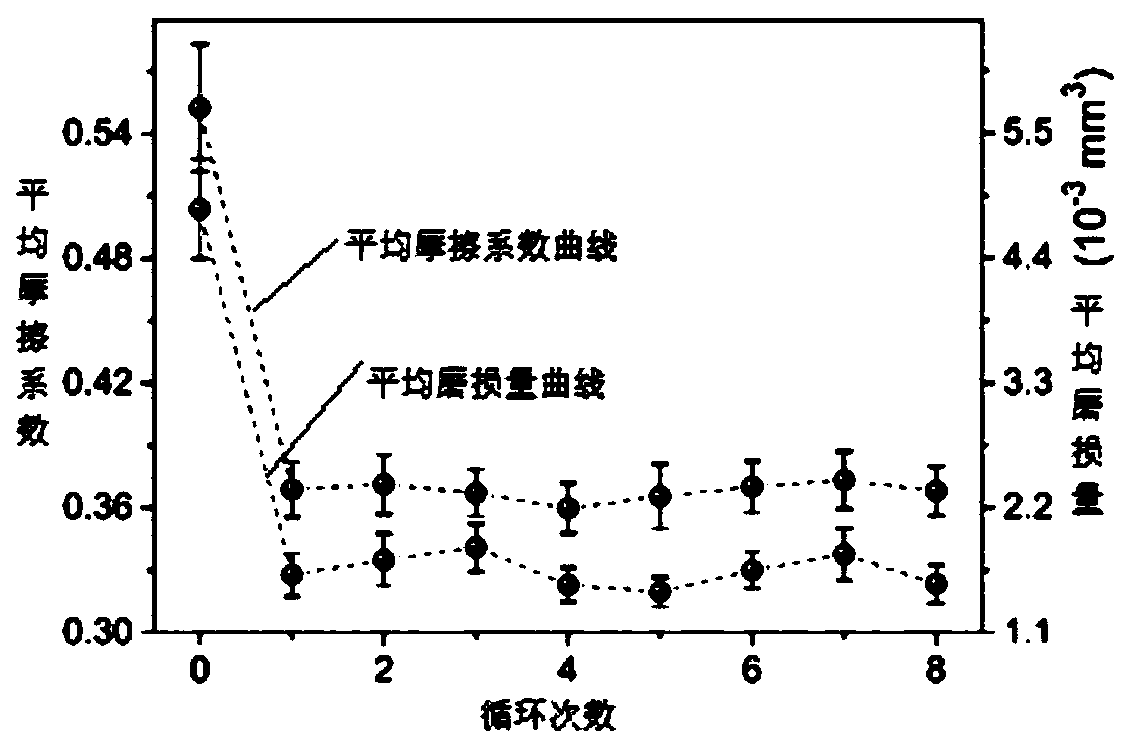

[0107] Based on the amidation reaction, a recyclable carbon quantum dot nano-lubricating oil additive was prepared by a one-step pyrolysis method, and C 6 h 8 o 7 ·H 2 O as the carbon source, n-octanol as the reaction medium, 3-(dibutylamino)propylamine, 1,4-bis(3-aminopropyl)piperazine, (s)-2-(aminomethyl)-1 -Ethylpyrrolidine and N,N-diisopropylethylenediamine respectively replace 2-amino-5-diethylaminopentane as functional reagents, the corresponding addition amount and molar ratio remain unchanged, and the corresponding experimental scheme refers to Embodiment 1, the R of the product that embodiment 2-5 obtains is hydroxyl, carboxyl and carbonyl, epoxy group. The corresponding experimental parameters and experimental results are shown in Table 1:

[0108] Table 1 embodiment 2-5 experimental parameters and experimental results

[0109]

[0110]

[0111] As can be seen from the results in Table 1, 3-(dibutylamino)propylamine, 1,4-bis(3-aminopropyl)piperazine, (s)-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com