Flame-retardant and fire-resistant silicone rubber material and preparation method and application thereof

A flame retardant, refractory, silicone rubber technology, applied in the field of refractory materials, can solve unsafe, unenvironmental protection and other problems, achieve good mechanical properties, good flame retardant effect, and improve the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

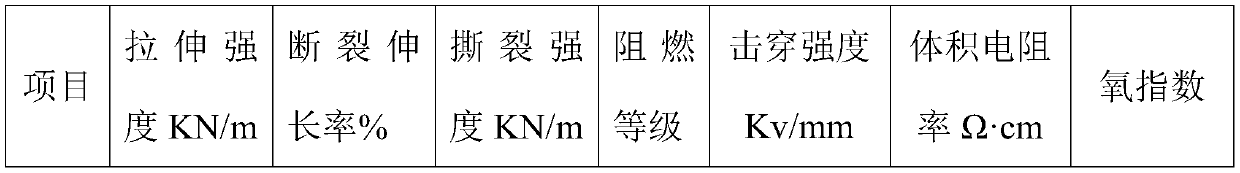

Image

Examples

preparation example Construction

[0044] In addition, the present invention also provides a kind of preparation method of flame-retardant refractory silicone rubber material as described above, and this preparation method comprises the steps:

[0045] Step S1. kneading the silicone rubber in a kneader, the kneading temperature is less than or equal to 110°C;

[0046] Step S2. Add the organosiloxane into a kneader and knead evenly, and knead at room temperature for 10 to 20 minutes to form a lump material;

[0047] Step S3. Add the reinforcing filler into a kneader and knead evenly, and knead at room temperature for 10-20 minutes to form a doughy material;

[0048] Step S4. Add the flame retardant to a kneader and knead evenly, and knead at room temperature for 10 to 20 minutes to form a doughy material;

[0049] Step S5. Add the refractory filler into a kneader and knead evenly, and knead at room temperature for 10 to 20 minutes to form a doughy material;

[0050] Step S6. Add the other additives into a knea...

Embodiment 1

[0058] In the present embodiment, each part by weight is composed as follows: 100 parts by weight of silicone rubber; 39 parts by weight of organosiloxane; 40 parts by weight of reinforcing filler white carbon black, 10 parts by weight of silicon micropowder; 150 parts by weight of flame retardant magnesium hydroxide Parts, 5 parts by weight of piperazine, 100 parts by weight of polyphosphate, 40 parts by weight of hypopolyphosphate, 5 parts by weight of platinum flame retardant; 100 parts by weight of refractory filler mineral silicate, 30 parts by weight of metal oxide glass powder, 100 parts by weight of boric acid Parts by weight, 50 parts by weight of vermiculite powder; auxiliary agent is 151 2 parts by weight of coupling agent, 2 parts by weight of coupling agent 171 ; 10 parts by weight of stearic acid.

[0059] The above-mentioned raw materials formed in parts by weight are operated according to steps S1 to S10 disclosed in the preparation method of the above-mentioned...

Embodiment 2

[0074] In the present embodiment, the components by weight are as follows: 100 parts by weight of silicone rubber; 15 parts by weight of organosiloxane; 30 parts by weight of reinforcing filler white carbon black, 20 parts by weight of diatomaceous earth; 50 parts by weight of flame retardant magnesium hydroxide Parts by weight, 5 parts by weight of piperazine, 10 parts by weight of thiophosphate, 150 parts by weight of hypopolyphosphate; 50 parts by weight of refractory filler mineral silicate, 30 parts by weight of metal oxide glass powder, 60 parts by weight of boric acid, 20 parts by weight of vermiculite powder parts by weight; auxiliary agent is coupling agent 151 2 parts by weight, coupling agent 171 2 parts by weight; zinc stearate 5 parts by weight.

[0075] The raw materials composed of the above-mentioned parts by weight are operated according to the steps S1 to S10 disclosed in the preparation method of the above-mentioned flame-retardant and refractory silicone rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com