Modified nano cerium oxide, preparation method thereof, modified nano cerium oxide flame-retardant polyformaldehyde and preparation method thereof

A technology of nano-cerium oxide and polyoxymethylene, applied in the fields of modified nano-cerium oxide and its preparation, modified nano-cerium oxide flame-retardant polyoxymethylene and its preparation, can solve the problems of poor dispersion and easy agglomeration of nano-cerium oxide, and achieve Enhanced compatibility, improved dispersibility, and improved flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a modified nano-cerium oxide, including a modifier, nano-cerium oxide, deionized water and ethanol, wherein the modifier is polyethylene glycol, stearic acid, sodium dodecylsulfonate, Any one or a combination of sodium lauryl sulfate, KH550 and KH570, the mass of the modifier is 1% to 7% of the mass of nano cerium oxide.

[0055] Unmodified nano cerium oxide has the characteristics of easy aggregation, hydrophilic and oleophobic, and poor compatibility with polyoxymethylene and other polymers; the modified nano cerium oxide provided in this example has obviously improved its dispersibility after modification, The compatibility with polyoxymethylene is also significantly improved, improving its flame retardant performance against polyoxymethylene.

Embodiment 2

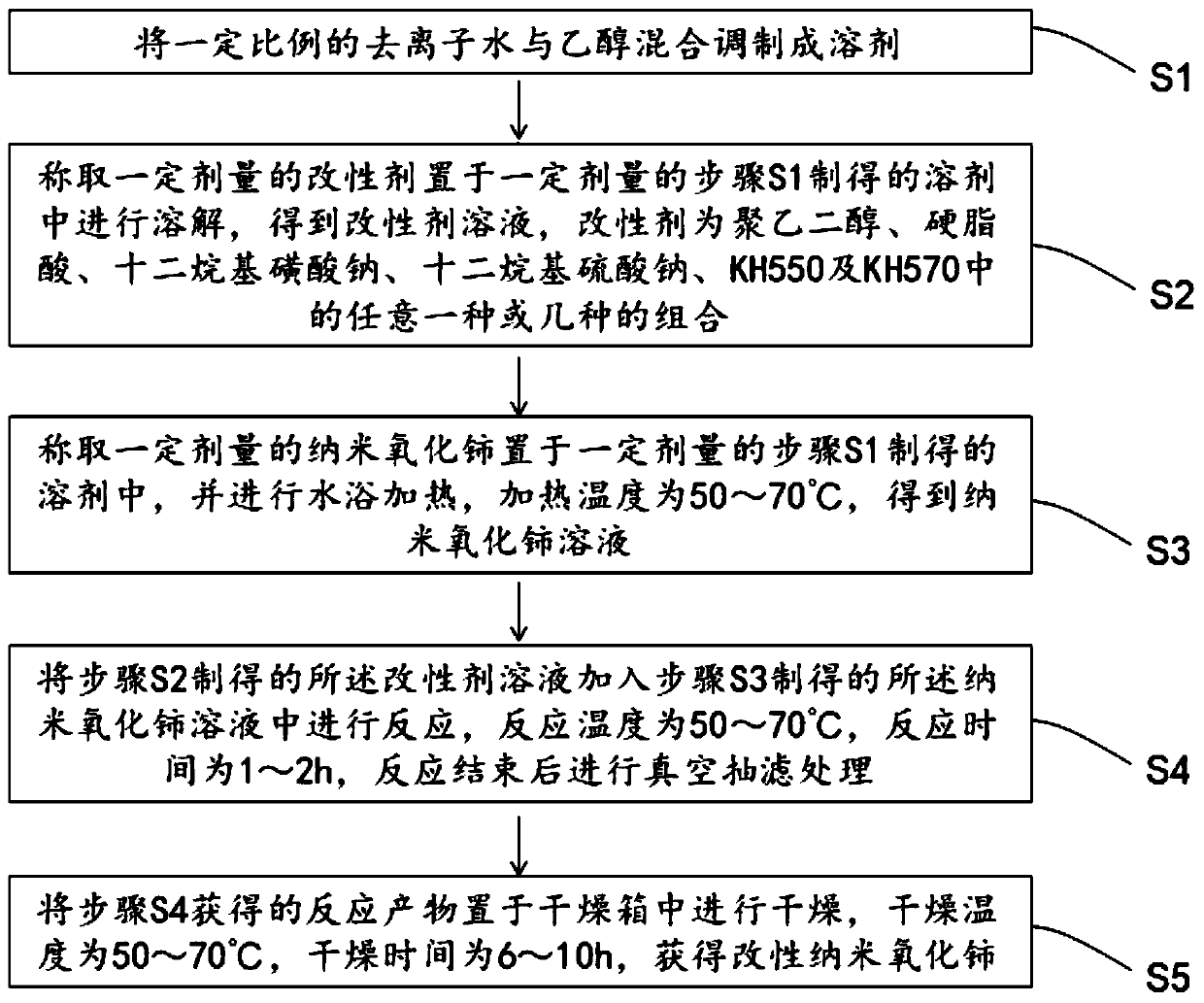

[0057] see figure 1 As shown, the present embodiment provides a preparation method of modified nano-cerium oxide, comprising the following steps:

[0058] S1: Mix a certain proportion of deionized water and ethanol to prepare a solvent. In this embodiment, the ratio of deionized water and ethanol is 1:1 to 2:1;

[0059] S2: Weigh a certain dose of modifier and place it in the solvent prepared in step S1 to dissolve it to obtain a modifier solution. In this embodiment, a high-speed disperser is used to fully stir so that the modifier is fully Dissolving, the modifying agent is any one or a combination of polyethylene glycol, stearic acid, sodium lauryl sulfate, sodium lauryl sulfate, KH550 and KH570;

[0060] S3: Weighing a certain dose of nano-cerium oxide, placing it in a certain dose of the solvent prepared in step S1, and heating it in a water bath to a temperature of 50-70° C. to obtain a nano-cerium oxide solution;

[0061] In this embodiment, a certain dose of nano ce...

Embodiment 3

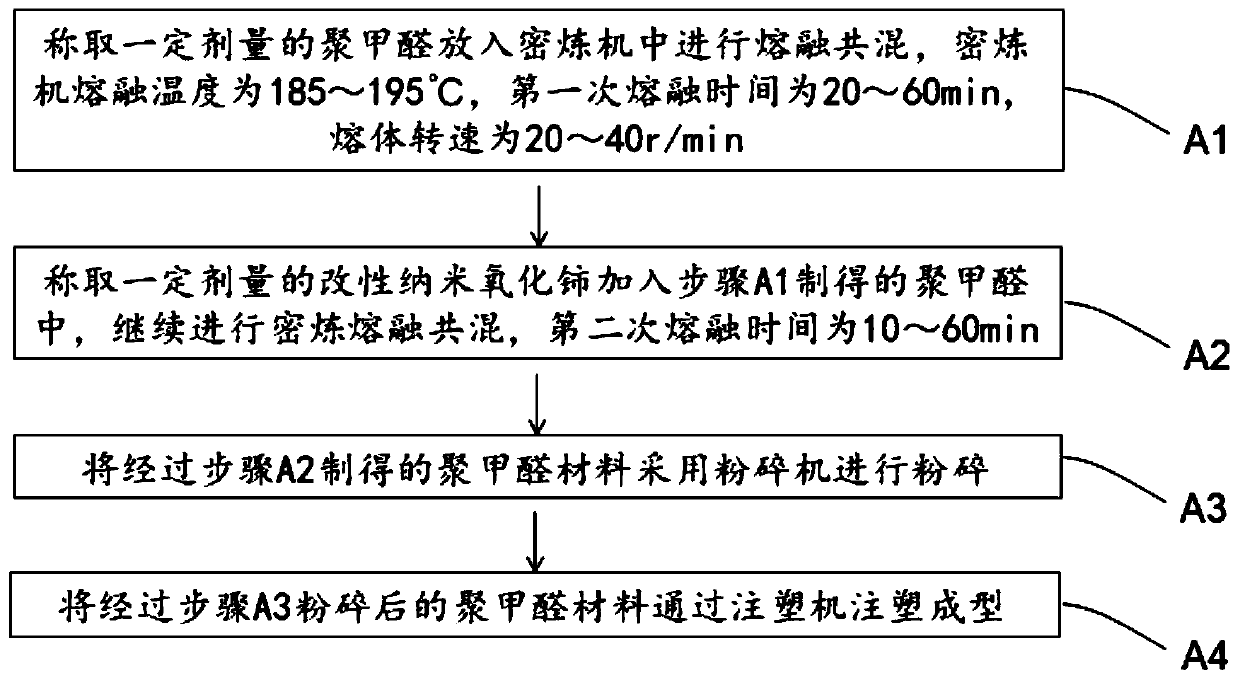

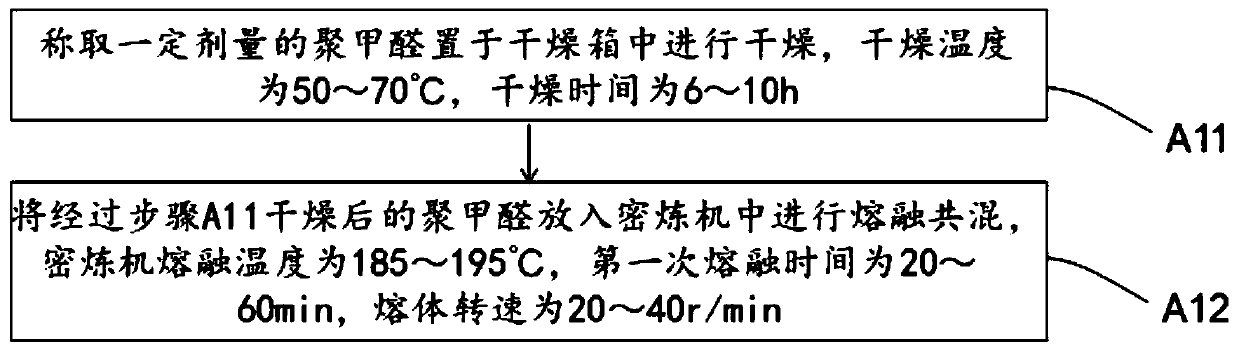

[0066] This embodiment provides a modified nano-cerium oxide flame-retardant polyoxymethylene, including the modified nano-cerium oxide and polyoxymethylene described in Example 1, and the quality of the modified nano-cerium oxide is 0.5% to 10% of the mass of polyoxymethylene . In this example, the flame retardancy of polyoxymethylene was significantly improved by adding modified nano-cerium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com