Graphene oxide waste conversion and recovery device and method thereof

A technology of a recovery device and a recovery method, applied in the field of graphene oxide waste conversion and recovery devices, can solve the problems of large cleaning water consumption, high slurry viscosity, difficult solid content, etc., and achieves improved processing efficiency, simple operation method, and accelerated reduction. effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

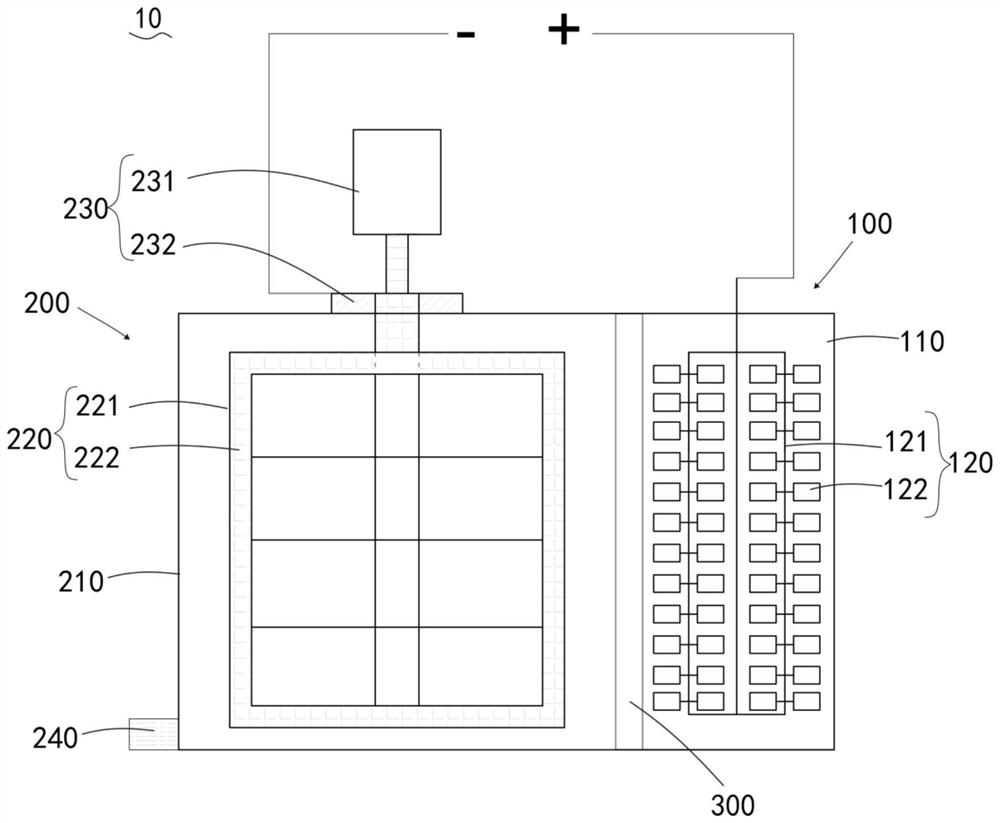

[0071] The present embodiment provides a graphene oxide waste conversion and recovery method. Use the graphene oxide waste conversion and recovery method of the above-mentioned graphene oxide waste conversion and recovery device 10, comprising the steps:

[0072]Step 1: Add graphene oxide slurry to the cathode reaction chamber 210 , and add water to the anode reaction chamber 110 . The height of adding water into the anode reaction chamber 110 does not exceed 2 / 3 of the height of the inner wall of the anode reaction chamber 110 . When the graphene oxide slurry is solid, the graphene oxide waste is soaked for 3-12 hours before being added to the cathode reaction chamber 210 .

[0073] Step 2: Control the second electrode 220 to rotate at a speed of 50 rpm.

[0074] Step 3: Connect the first electrode 120 to the positive pole of the power supply, connect the second electrode 220 to the cathode of the power supply, and use a direct current with a voltage of 0.5-3V to carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com