Flexural and durable cement-based composite material containing PP fiber

A composite material and cement-based technology, applied in the field of building materials, can solve the problems of poor tolerance, weak bonding force, and disintegration of cement-based composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

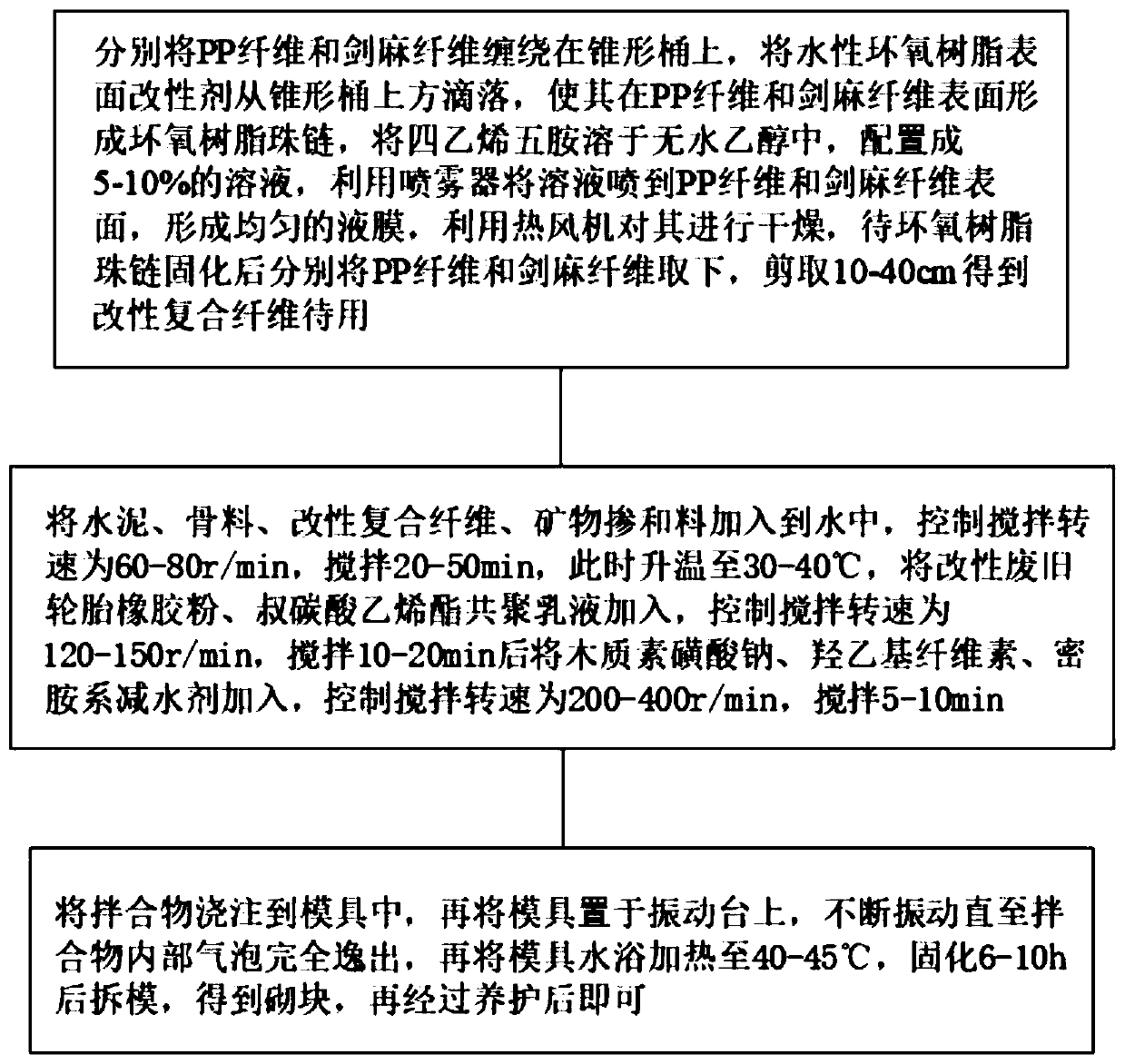

Method used

Image

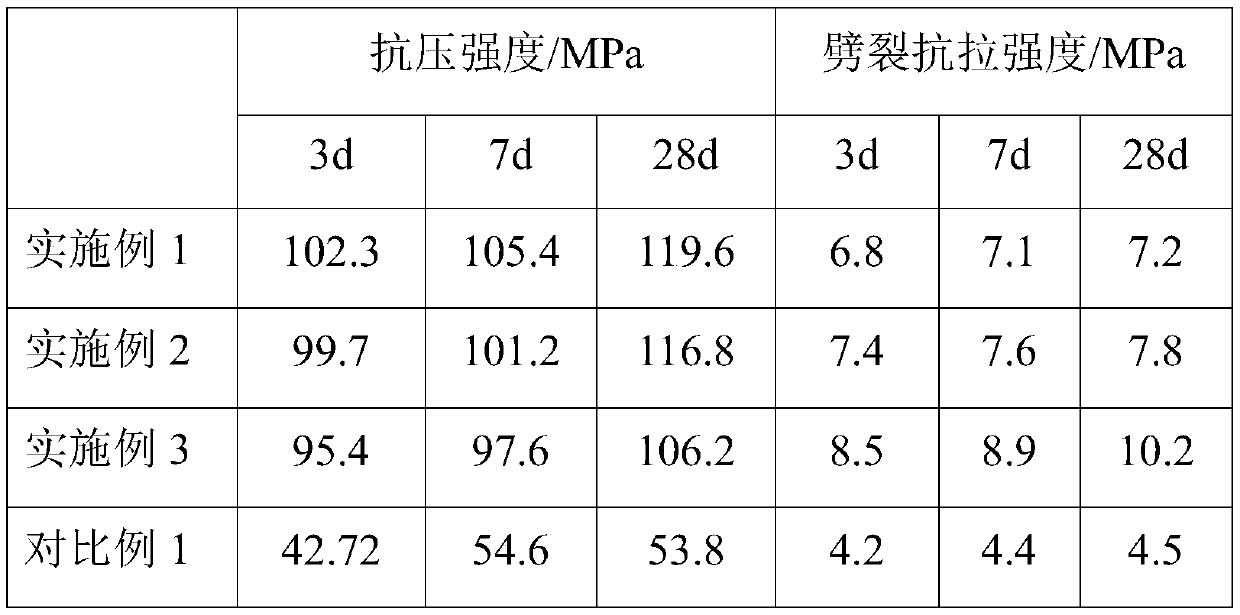

Examples

Embodiment 1

[0027] A kind of anti-bending and durable cement-based composite material containing PP fiber, consisting of the following components by weight:

[0028] 33 parts of cement, 40 parts of aggregate made by mixing river sand with a particle size of 2-5 mm and river sand with a particle size of 0.5-1 mm in a weight ratio of 1:1, 14 parts of PP fiber, 10 parts of sisal fiber, Fly ash, granulated blast furnace slag, and silica fume powder are mixed in a weight ratio of 1:1:1, 20 parts of mineral admixture, 8 parts of modified waste tire rubber powder, 2 parts of sodium lignin sulfonate, hydroxyethyl 4 parts of base cellulose, 0.4 parts of tetraethylenepentamine, 2 parts of melamine-based water reducer, 2 parts of water-based epoxy resin BASF-1455, 15 parts of tertiary vinyl ester copolymer emulsion, and 30 parts of water.

[0029] The preparation method of above-mentioned modified waste tire rubber powder is as follows:

[0030] Add sorbitan monopalmitate and polyvinyl alcohol to w...

Embodiment 2

[0034] A kind of anti-bending and durable cement-based composite material containing PP fiber, consisting of the following components by weight:

[0035] 50 parts of cement, 30 parts of aggregate mixed with river sand with a particle size of 2-5 mm and river sand with a particle size of 0.5-1 mm in a weight ratio of 1:1, 12 parts of PP fiber, 7 parts of sisal fiber, Granulated blast furnace slag and shell powder are mixed at a weight ratio of 1:1, 16 parts of mineral admixture, 6 parts of modified waste tire rubber powder, 1.2 parts of sodium lignosulfonate, 3 parts of hydroxyethyl cellulose, four parts 0.4 parts of ethylene pentamine, 2 parts of melamine-based water reducer, 4 parts of water-based epoxy resin BASF-1422, 12 parts of vinyl tertiary carbonate copolymer emulsion, and 25 parts of water.

[0036] The preparation method of above-mentioned modified waste tire rubber powder is as follows:

[0037] Add sorbitan monopalmitate and polyvinyl alcohol to water 100 times its ...

Embodiment 3

[0041] A kind of anti-bending and durable cement-based composite material containing PP fiber, consisting of the following components by weight:

[0042] 40 parts of cement, 35 parts of aggregate made by mixing river sand with a particle size of 2-5 mm and river sand with a particle size of 0.5-1 mm in a weight ratio of 1:1, 10 parts of PP fiber, 5 parts of sisal fiber, 12 parts of steel slag powder, 6 parts of modified waste tire rubber powder, 1 part of sodium lignosulfonate, 3 parts of hydroxyethyl cellulose, 0.8 parts of tetraethylenepentamine, 3 parts of melamine-based water reducer, water-based epoxy resin 4 parts of BASF-1455, 12 parts of vinyl tertiary carbonate copolymer emulsion, 25 parts of water.

[0043] The preparation method of above-mentioned modified waste tire rubber powder is as follows:

[0044] Add sorbitan monopalmitate and polyvinyl alcohol to water 100 times its total weight at a weight ratio of 1:1, stir in a water bath at 50°C for 15 minutes, add was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com