Medical waste staged treatment device and method

A technology for medical waste and grading treatment, applied in water/sewage multi-stage treatment, filtration treatment, special treatment targets, etc., can solve the problems of long time insulation and pressure preservation, long overall process, complicated treatment procedures, etc., and achieve volume reduction. , strengthen the drying effect, strengthen the effect of the screening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

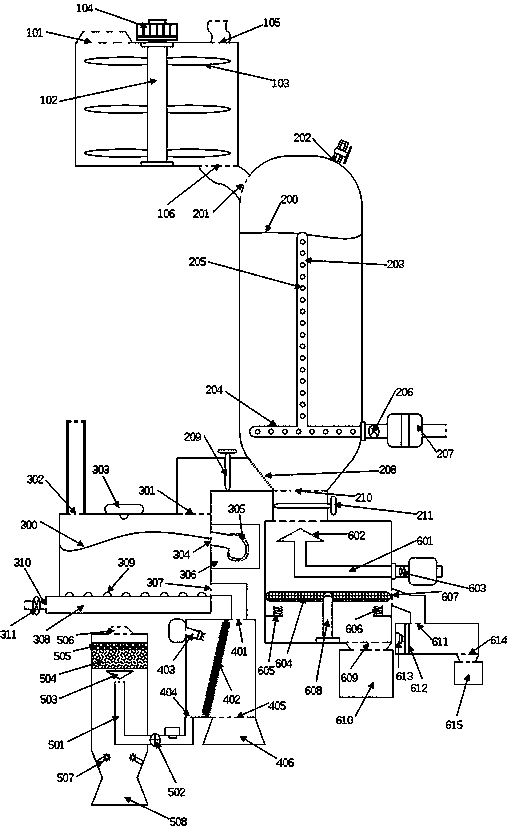

[0036] Further explanation in conjunction with accompanying drawings: figure 1 It is a structural diagram of the internal view of the medical waste classification treatment device of this embodiment, including a mixing chamber, a high-pressure hydrolysis unit, a sewage treatment unit and a mixing treatment unit.

[0037] like figure 1 As shown, the mixing chamber includes a mixing chamber inlet 101, a stirring shaft 102, a stirring blade 103, a stirring motor 104, a mixing chamber water inlet 105 and a mixing chamber outlet 106; The feed port is arranged on the top wall of the mixing chamber for discharging medical waste into the mixing chamber, the stirring shaft is vertically arranged in the mixing chamber, the stirring blades are evenly distributed on the stirring shaft, and the stirring motor It is arranged outside the mixing chamber and connected with the stirring shaft through a coupling to drive the rotation of the stirring shaft. The water inlet of the mixing chamber ...

Embodiment 2

[0046] A method for graded treatment of medical waste, which is carried out using the device for graded treatment of medical waste in Example 1, specifically comprising the following steps:

[0047] 1) Put the medical waste into the mixing chamber through the material inlet of the mixing chamber, and at the same time open the water inlet of the mixing chamber to discharge tap water, start the stirring motor, and open the outlet of the mixing chamber after 5 minutes to discharge the materials.

[0048] 2) Put the material discharged from the discharge port of the mixing chamber into the high-pressure tank through the feed port of the high-pressure tank. When the material in the high-pressure tank reaches 10% of the total volume, open the horizontal inlet pipe and start the booster pump for the high-pressure tank, adjust the air temperature in the gas heating chamber to 115°C, and open the exhaust port of the high-pressure tank at the same time.

[0049] 3) When the material in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com