Cutting apparatus and cutting tool trimming method

A cutting tool and cutting device technology, which is applied to fine working devices, parts of grinding machine tools, abrasive surface adjustment devices, etc., can solve problems such as long time and achieve the effect of efficient dressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

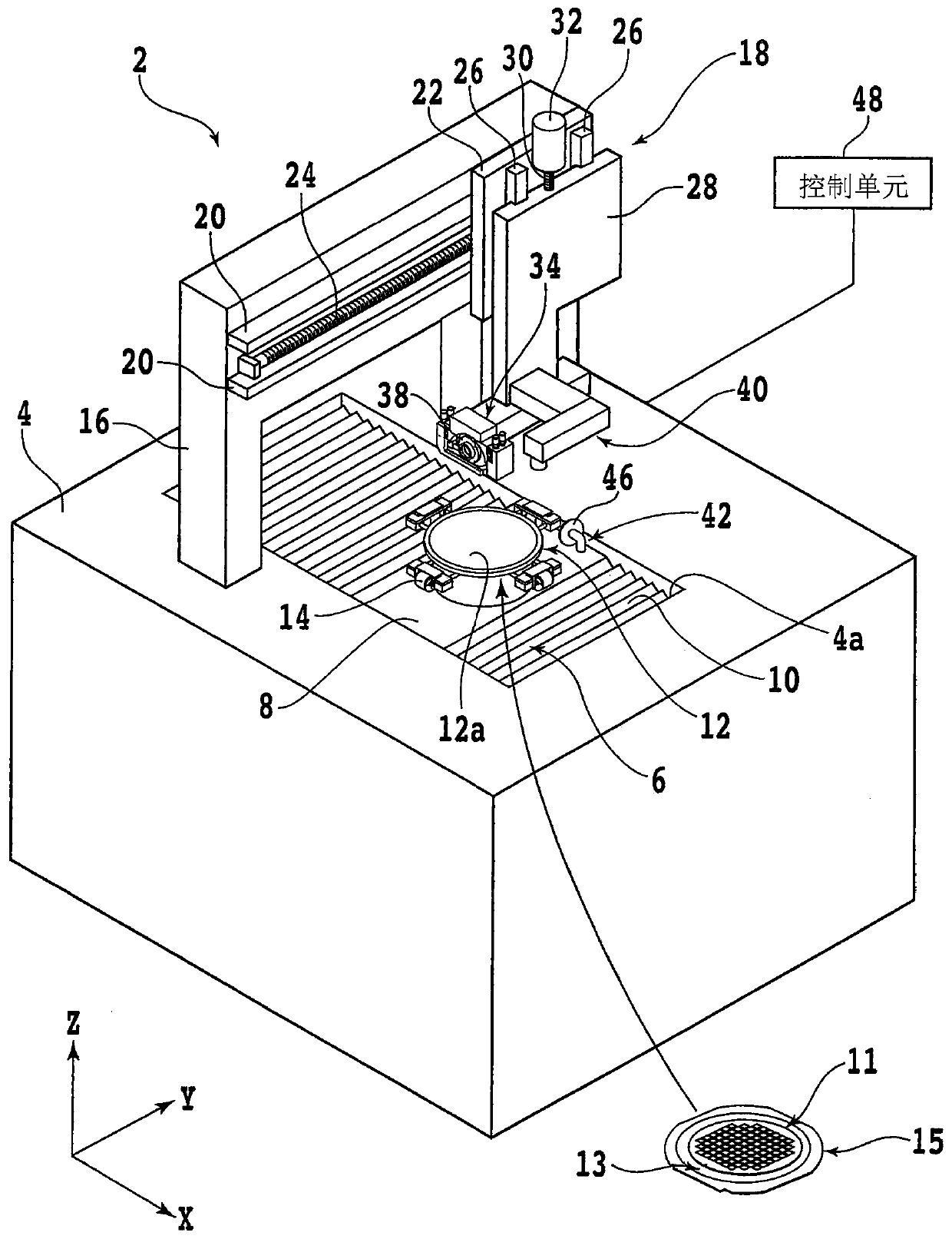

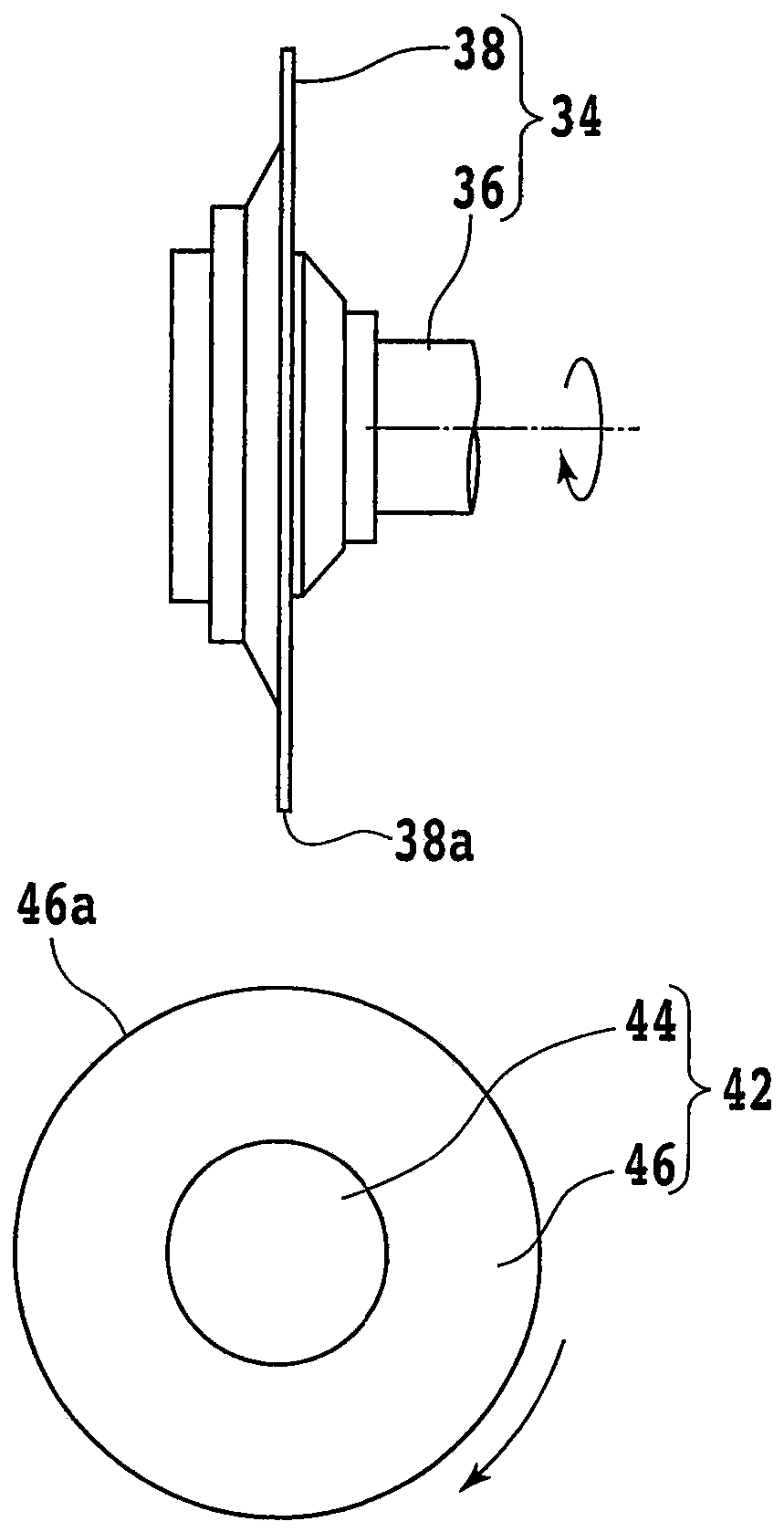

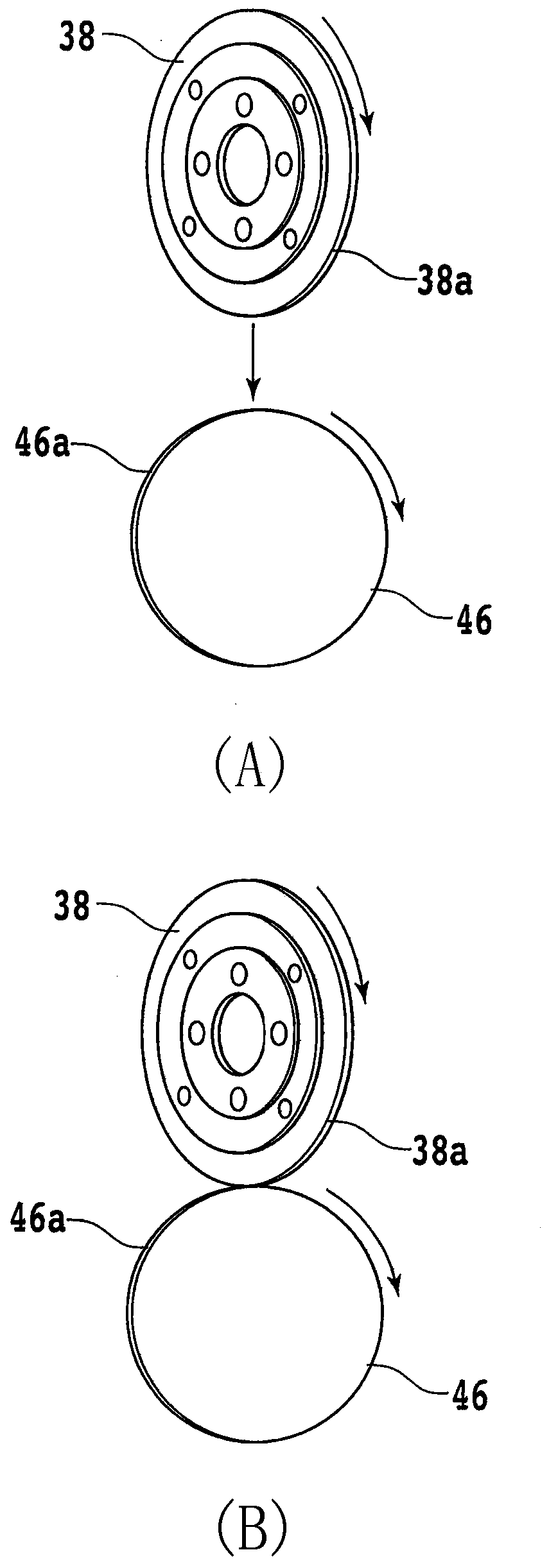

[0017] An embodiment of one embodiment of the present invention will be described with reference to the drawings. figure 1 It is a perspective view showing the cutting device 2 of this embodiment. Such as figure 1 As shown, the cutting device 2 has a base 4 that supports each component. An opening 4 a long in the X-axis direction (front-rear direction, machining feed direction) is formed on the upper surface of the base 4 .

[0018] A ball screw type X-axis moving mechanism (machining feed mechanism) 6 is arranged in the opening 4a. The X-axis moving mechanism 6 has an X-axis moving table (not shown), and moves the X-axis moving table in the X-axis direction. In addition, the X-axis moving mechanism 6 and the upper part of the X-axis moving table are covered with a table cover 8 and a corrugated cover 10 .

[0019] A chuck table (holding table) 12 for holding a plate-shaped workpiece 11 is arranged on the X-axis movable table so as to be exposed from the table cover 8 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com