Graphene-metal modified nano heavy anti-corrosion coating as well as preparation method and preparation system thereof

A metal modification and graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems that anti-corrosion methods cannot achieve good results, and achieve good adhesion, anti-corrosion performance, and excellent corrosion resistance Performance, the effect of accelerating solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

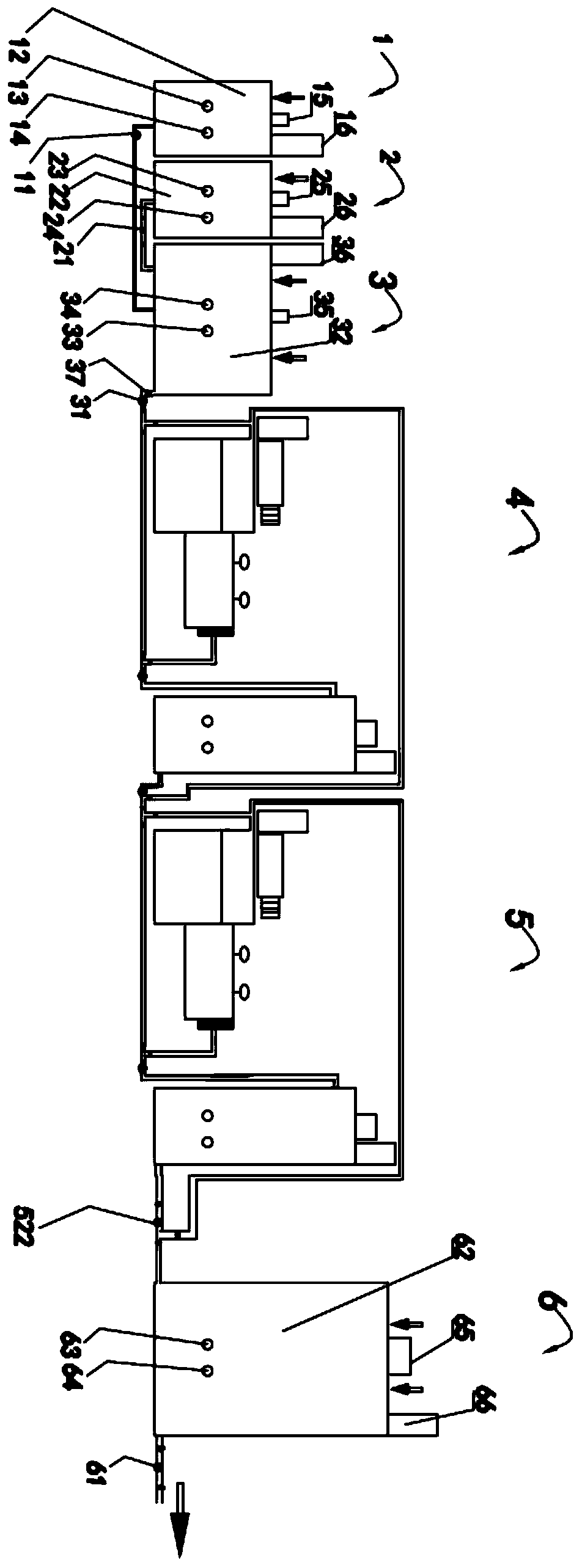

[0053] In order to obtain the anticorrosion coating provided by the present invention, the present invention also provides a kind of preparation method of graphene metal nano anticorrosion coating, and its step comprises:

[0054] a) 3-5% of fluorinated carbon, 2-4% of graphite powder, 2-2.6% of dispersant, 5-7% of diluent and 16-18% of epoxy resin in the first preliminary stage according to the proportion Mix in the mixing tank equipment and stir at a low speed for 20 minutes to obtain the first premix;

[0055] b) 2-4% titanium powder, 2-4% zinc powder, 2-4% niobium powder, 2-4% nickel powder, 2-4% iron powder, 4-6.4% dispersant, 11-13% of the diluent and 32-37% of the epoxy resin are mixed in the second pre-mixing tank equipment according to the ratio and stirred at a low speed for 20 minutes to obtain the second pre-mixture;

[0056] c) The first pre-mixture obtained in step a) and the second pre-mixture obtained in step b) are transported to the primary mixing tank equip...

Embodiment 1

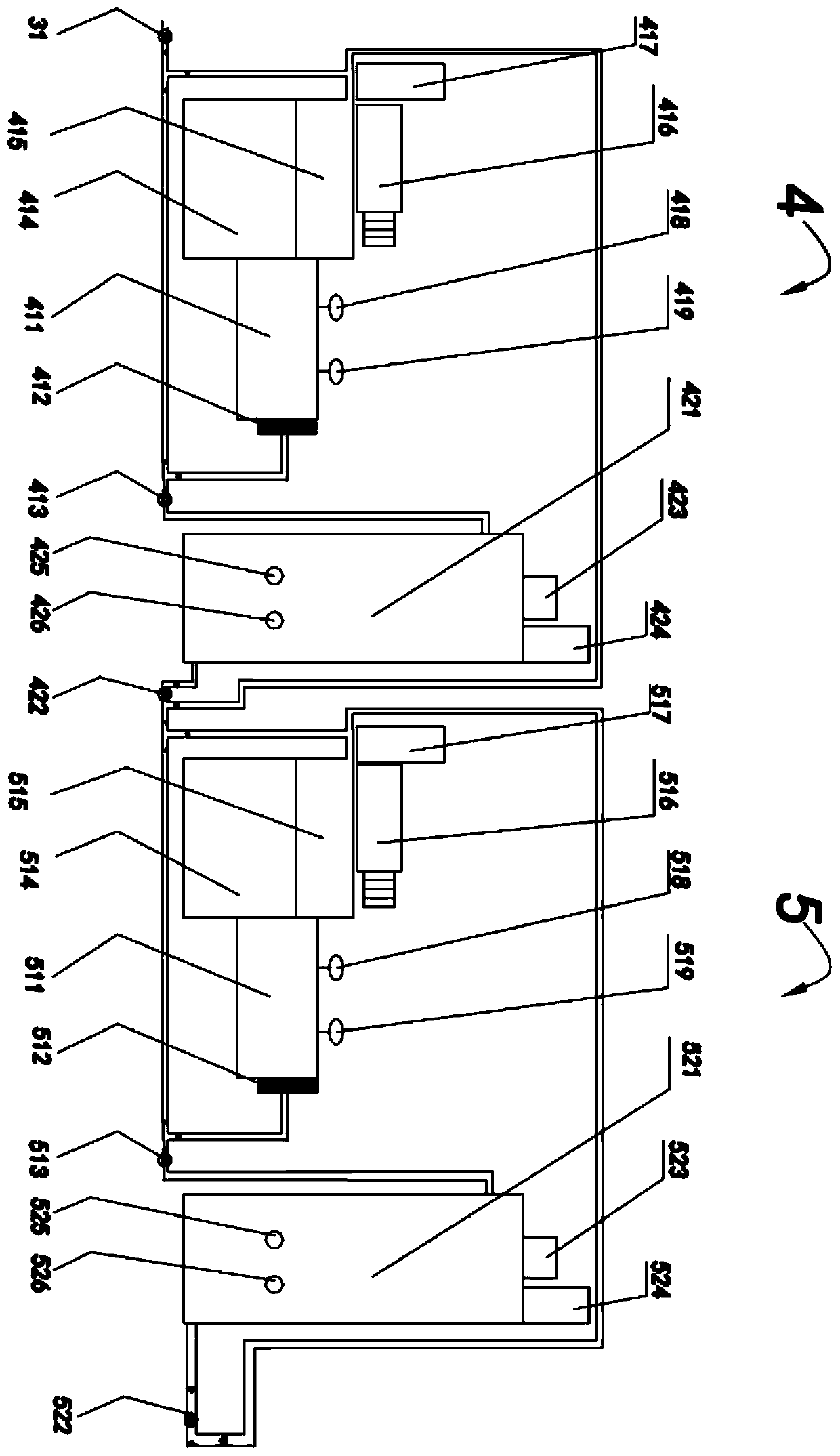

[0108]Add 3% graphite, 4% carbon fluoride, 16.5% epoxy resin, 5.7% diluent and 2.2% dispersant in the first mixing tank 12 of the first pre-mixing tank device 1, with the first The stirring rate of the 1 / 4 power of the full power of the motor 15 was stirred for 20 minutes to obtain the first premixture; in the second mixing tank 22, add 3% titanium powder, 3% zinc powder, 3% niobium powder, 3% Nickel powder, 3% iron powder, 35.5% epoxy resin, 12.3% diluent and 5.8% dispersant were stirred for 20 minutes at a stirring rate of 1 / 4 power of the full power of the second electric motor 25 to obtain the second Two premixes. The first premix and the second premix are transferred to the third mixing tank 32 and stirred at a 1 / 2 power stirring rate of the full power of the third motor for 30 hours to obtain the primary mixture. Utilize the third pump 31 to transfer the primary mixture to the primary zirconium bead grinding equipment 4 for grinding, the diameter of the zirconium beads ...

Embodiment 2

[0110] Add 2% graphite, 3% carbon fluoride, 16% epoxy resin, 5% diluent and 2% dispersant in the first mixing cylinder 12 of the first pre-mixing cylinder device 1, with the first The stirring rate of the 1 / 4 power of the full power of the motor 15 was stirred for 20 minutes to obtain the first premix; in the second mixing tank 22, 2% titanium powder, 2% zinc powder, 2% niobium powder, 2% niobium powder were added. Nickel powder, 2% iron powder, 37% epoxy resin, 11% diluent and 4% dispersant were stirred for 20 minutes at a stirring rate of 1 / 4 power of the full power of the second motor 25 to obtain the second Two premixes. The first premix and the second premix were transferred to the third mixing tank 32 and stirred at a 1 / 2 power stirring rate of the full power of the third motor for 30 hours to obtain the primary mixture. Utilize the third pump 31 to transfer the primary mixture to the primary zirconium bead grinding equipment 4 for grinding, the diameter of the zirconiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com