Low-temperature-resistant high-strength polyurethane tire and preparation process thereof

A polyurethane tire and high-strength technology, which is applied in the field of polyurethane tires, can solve the problems of polyurethane tire tensile strength reduction, poor low-temperature strength and low-temperature strength of polyurethane tires, and achieve faster curing speed, good adhesion, and improved low-temperature strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

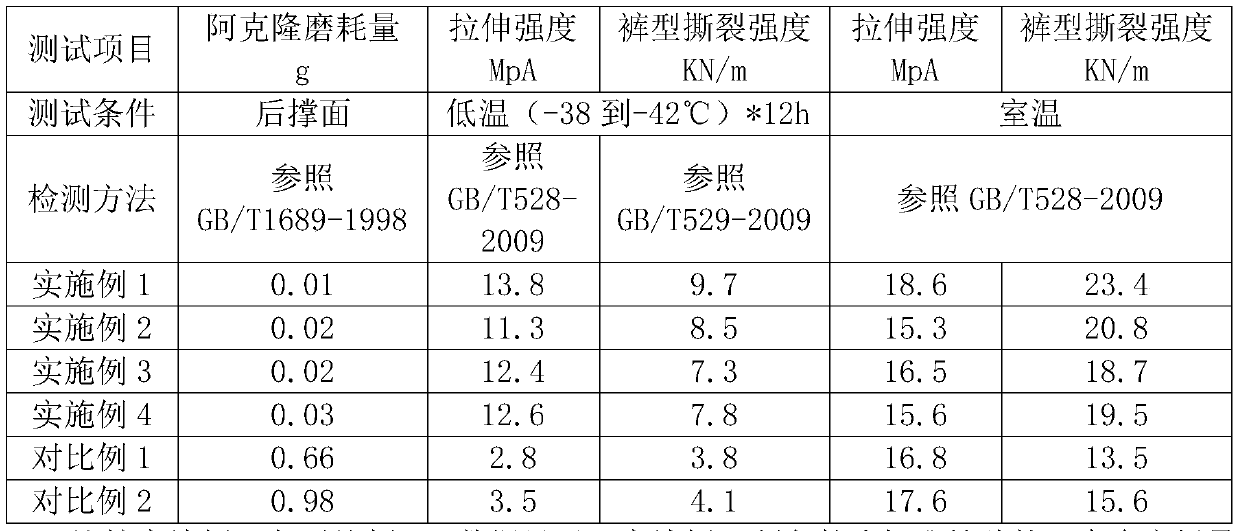

Examples

Embodiment 1

[0031] A preparation process for low-temperature-resistant high-strength polyurethane tires, step 1, dehydrating 1000g of polyacrylate polyol, controlling the dehydration reaction temperature to 113°C, and the reaction time is 4 hours; then adding 200g of liquefied MDI at 78°C Down mixing reaction, the reaction time is 2 hours, to prepare the prepolymer.

[0032] Step 2, 100g of curing agent, 50g of liquid methyl silicone rubber (viscosity ≤ 8000mPa·s at 25°C), 40g of PTFE micropowder with a particle size of 0.8μm, 20g of di-tert-butyl peroxide, 10g of flame retardant Add the antioxidant and 10g of antioxidant into the mixer, and stir for 0.5 hour at room temperature with a stirring speed of 140rpm to prepare the auxiliary material.

[0033] Step 3, put the prepolymer prepared in step 1 and the auxiliary materials prepared in step 2 into tanks A and B of the pouring machine respectively, mix and pour them into the tire casting mold according to the above weight ratio, and vulc...

Embodiment 2

[0036] A preparation process for low-temperature-resistant high-strength polyurethane tires, step 1, dehydrating 800g of polyacrylate polyol, controlling the dehydration reaction temperature to be 110°C, and the reaction time is 4.5 hours; then adding 250g of liquefied MDI at 70°C Down mixing reaction, the reaction time is 2.5 hours, to prepare the prepolymer.

[0037] Step 2, 100g of curing agent, 100g of liquid methyl silicone rubber (viscosity ≤ 8000mPa·s at 25°C), 20g of PTFE micropowder with a particle size of 0.5μm, 30g of di-tert-butyl peroxide, 5g of flame retardant Add the antioxidant and 5g of antioxidant into the mixer, and stir for 0.3 hours at room temperature with a stirring speed of 120rpm to prepare auxiliary materials.

[0038] Step 3, put the prepolymer prepared in step 1 and the auxiliary materials prepared in step 2 into tanks A and B of the pouring machine respectively, mix and pour them into the tire casting mold according to the above weight ratio, and v...

Embodiment 3

[0041] A preparation process for low-temperature-resistant high-strength polyurethane tires, step 1, dehydrating 1500g of polyacrylate polyol, controlling the dehydration reaction temperature to 120°C, and the reaction time is 3.5 hours; then adding 150g of liquefied MDI at 90°C Down mixing reaction, the reaction time is 1 hour, and the prepolymer is prepared.

[0042] Step 2, 150g of curing agent, 50g of liquid methyl silicone rubber (viscosity ≤ 8000mPa·s at 25°C), 50g of polytetrafluoroethylene micropowder with a particle size of 15μm, 10g of di-tert-butyl peroxide, and 15g of flame retardant and 15g of antioxidant were added into a stirrer, stirred at room temperature for 1 hour, and the stirring speed was 200rpm to prepare auxiliary materials.

[0043] Step 3, put the prepolymer prepared in step 1 and the auxiliary materials prepared in step 2 into tanks A and B of the pouring machine respectively, mix and pour them into the tire casting mold according to the above weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com