Method for recycling phosphorus pentafluoride in lithium hexafluorophosphate synthesis tail gas by utilizing amine and derivatives thereof

A technology of lithium hexafluorophosphate and phosphorus pentafluoride, which is applied in lithium hexafluorophosphate, chemical instruments and methods, phosphorus halides/oxyhalides, etc., can solve the problems of restricting industrial reuse and difficulty in separation, so as to improve the utilization rate of raw materials, reduce losses, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

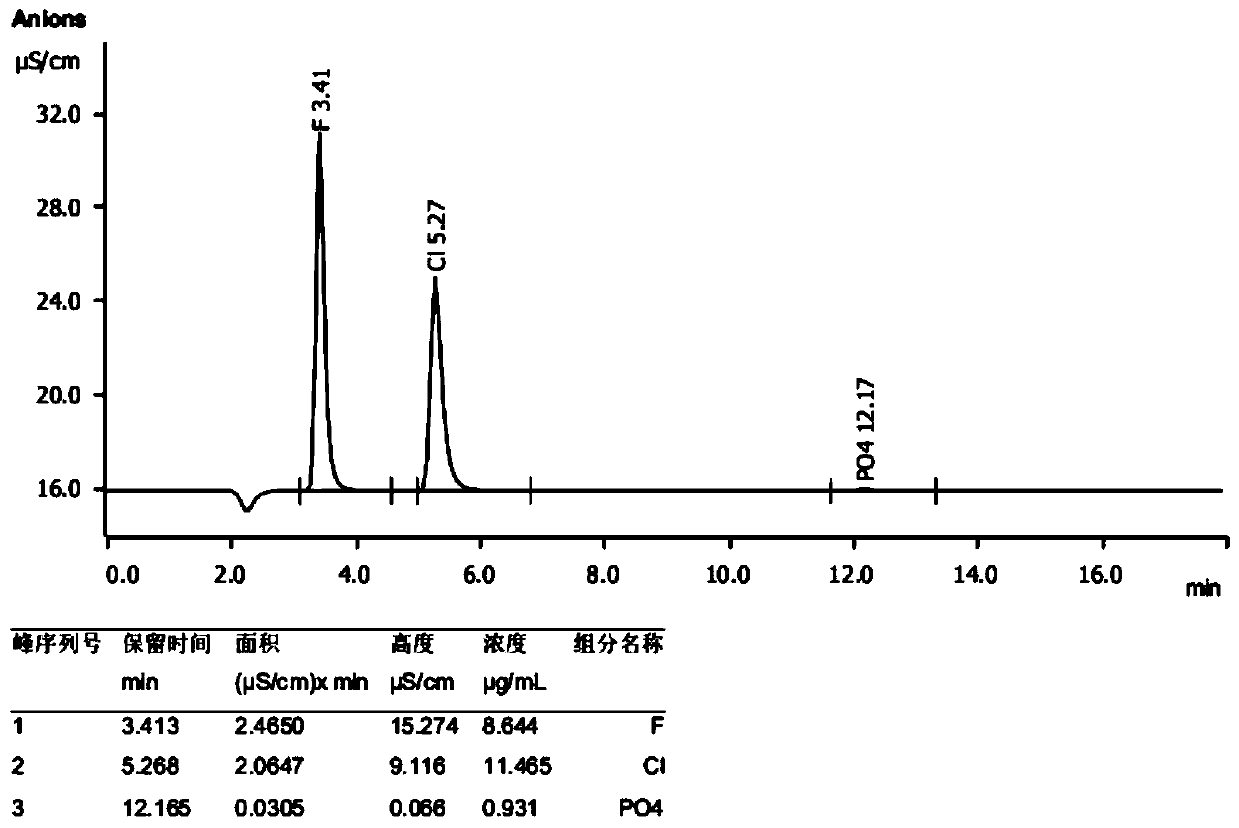

[0027] The tail gas of lithium hexafluorophosphate synthesis is a mixed gas of hydrogen fluoride, hydrogen chloride and phosphorus pentafluoride. Take a certain volume of mixed gas to measure the content of hydrogen fluoride, hydrogen chloride and phosphorus pentafluoride. The test method is as follows: absorb with three-stage sodium hydroxide lye, the size of the absorption tower is 40mm*300mm (inner diameter*height), and the packing of the absorption tower is uniform It is made of PTFE, Pall ring packing 5mm*φ5mm, the concentration of sodium hydroxide is 2% (w / w), and the alkali absorption solution is combined to determine F by ion chromatography - , Cl - and PO 4 3- The contents were 8.664μg / ml, 11.465μg / ml, 0.931μg / ml ( figure 1 ), according to a molecule of PF 5 After the lye is absorbed, a molecule of PO is produced 4 3- And the quantitative relationship of 5 molecules HF is converted into mass ratio, HF, HCl and PF 5 The mass ratio is 0.552 / 0.384 / 0.064 (w / w).

...

Embodiment 2

[0030] The ratio of hydrogen chloride, hydrogen fluoride and phosphorus pentafluoride in the tail gas of lithium hexafluorophosphate synthesis HCl: HF: PF 5=0.552:0.384:0.064 (w / w) (the measurement method is the same as that in Example 1). The mixed gas passes through the scrubber made of PTFE at a flow rate of 10mL / min. The internal size of the scrubber is 40mm*300mm (inner diameter*height), filled with 10*10 Pall ring packing, and the absorbent is benzylamine. The operating temperature is 40°C. The gas that comes out from scrubber passes through three-stage sodium hydroxide alkali absorption tower, and the size of absorption tower is the same as aforementioned scrubber, and the concentration of sodium hydroxide is 2% (w / w), and ion chromatography after alkali washing solution merges Determination of Cl - , F - and PO 4 3- The content is converted into HCl / HF / PF according to the mass ratio 5 = 0.575 / 0.40 / 0.025, PF 5 The absorption efficiency is 60.9%. Control the temp...

Embodiment 3

[0032] In a 500ml stainless steel container, add 250g of absorbent ethylamine, and then pass through PF with a concentration of 99.5% (V / V) 5 Stir while feeding the gas, maintain the pressure in the container at 0.1MPa, and the temperature at 0°C. After the pressure does not change any more, take out the contents of the container after maintaining for another hour. It is a red liquid, weighing 335g, according to the weight before and after The calculated absorption of change is 85g. Heating the vessel, when the temperature rises to 15°C, PF 5 Gas is released. It shows that ethylamine has a good absorption capacity for phosphorus pentafluoride, and can be used for the absorption and reuse of phosphorus pentafluoride in the tail gas of lithium hexafluorophosphate synthesis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com