Prepreg, laminate, and production methods therefor, as well as printed circuit board and semiconductor package

A technology of prepreg and manufacturing method, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of decreased resin strength, shortened molecular chain, decreased insulation reliability, etc., and achieves reduced warpage and low thermal expansion. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] Next, the present invention is further described in detail through the following examples, but these examples do not limit the present invention.

[0113] In addition, about the laminated board obtained in the following Example, the physical property or characteristic was measured and evaluated according to the following method.

[0114] (1) Determination of flexural modulus

[0115] An evaluation substrate of 40 mm x 25 mm was cut out from the laminate obtained in each example, and was set at 25° C., at a crosshead speed of 1 mm / min, at a fulcrum ( Japanese: span) measured flexural modulus (GPa) at a distance of 20mm.

[0116] (2) Evaluation of Feibai

[0117]The laminated board produced in each example was visually observed, and it evaluated based on the following evaluation criteria.

[0118] A: Blurring was not observed at all.

[0119] B: Only a small amount of whitening is observed.

[0120] C: Much whitening is observed.

[0121] (3) Determination of warpag...

manufacture example 1

[0124] Production example 1 (production of thermosetting resin composition 1)

[0125] "NC-3000H" (trade name, manufactured by Nippon Kayaku Co., Ltd.) as an epoxy resin, an addition reaction product of a bismaleimide compound and a diamine compound as a maleimide resin, and as a cured "G-8009L" (trade name, imidazole-blocked isocyanate (Japanese: イソゲシアネートマスクイミダゾール), manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.) as an accelerator, "YOSHINOX BB" (trade name, 4,4'- Butylenebis-(6-tert-butyl-3-methylphenol), produced by Mitsubishi Chemical Corporation) was mixed in a mixed solvent of methyl ethyl ketone and cyclohexanone to obtain a thermosetting resin composition with a solid content concentration of 55% by mass. Object 1.

Embodiment 1

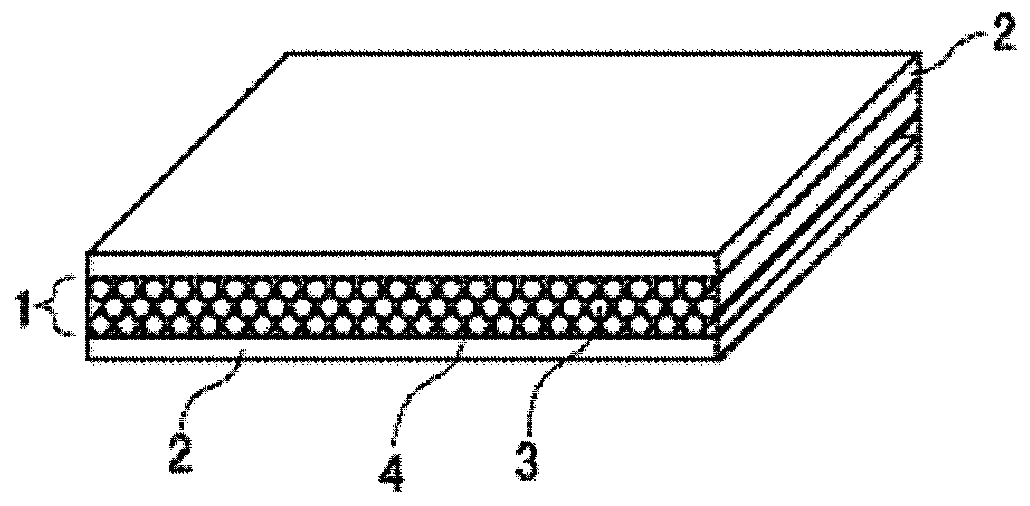

[0127] Using a polyethylene terephthalate film with a thickness of 38 μm as a carrier material, the thermosetting resin composition 1 obtained in Production Example 1 was coated on the above-mentioned carrier material with a thickness of 12 μm to form a resin coating with a thickness of 12 μm. Cloth film1.

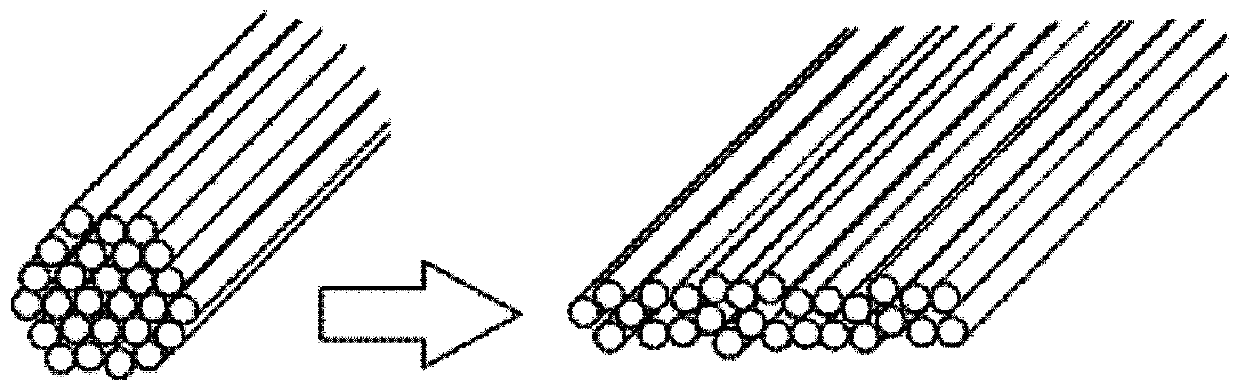

[0128] Next, a glass fiber bundle formed by bundling 6,000 glass fiber filaments with a fiber diameter (diameter) of 12 μm was opened at a fiber-opening ratio of 3.2 times, and the opened glass fiber filaments were arranged in a widthwise direction of 300 mm Wide, aligned on the above-mentioned resin coating film 1 with a thickness of 12 μm. Another resin coating film 1 having a thickness of 12 μm was attached thereon so that the resin coating surface faced downward.

[0129] The prepreg precursor thus obtained was B-staged using a hot roll at a pressure of 1 MPa, a temperature of 150° C., and a transport speed of 1 m / min to obtain a prepreg having a glass fiber content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com