Electrolytic paper for lightning-stroke-resistant capacitor and preparation method of electrolytic paper

A capacitor and electrolytic paper technology, applied in pulp beating method, special paper, paper and other directions, can solve the problems of lack of high pressure resistance, low overall strength, short circuit of capacitors, etc., to achieve improved pressure resistance, good moisture permeability, Reduce the effect of short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

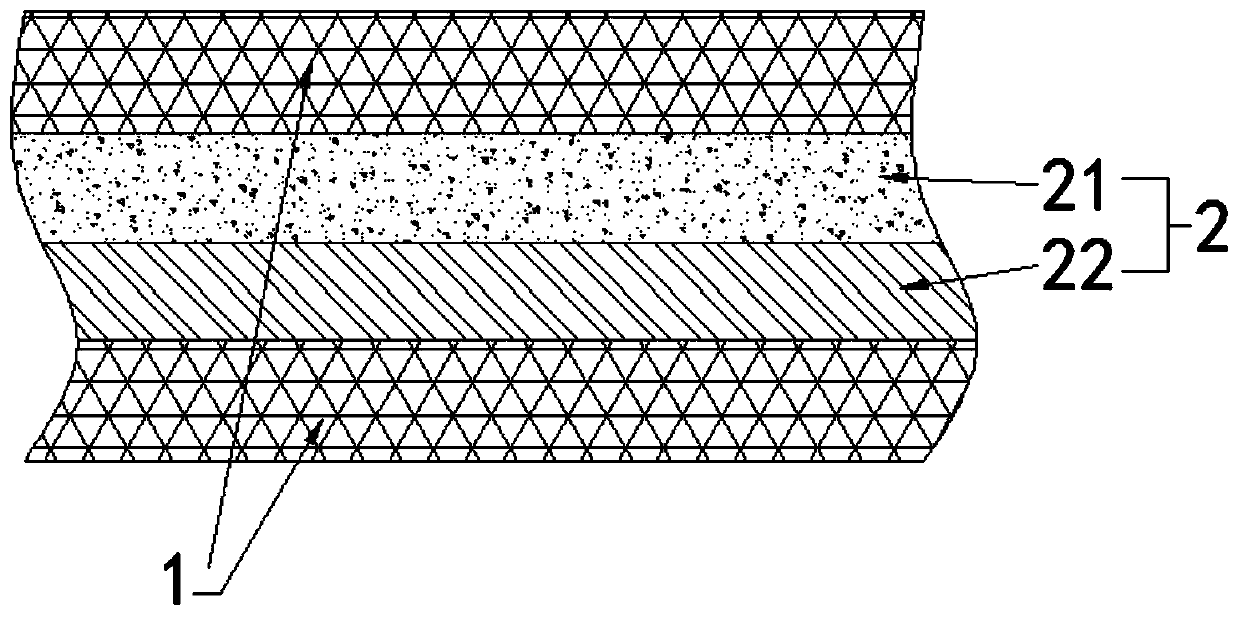

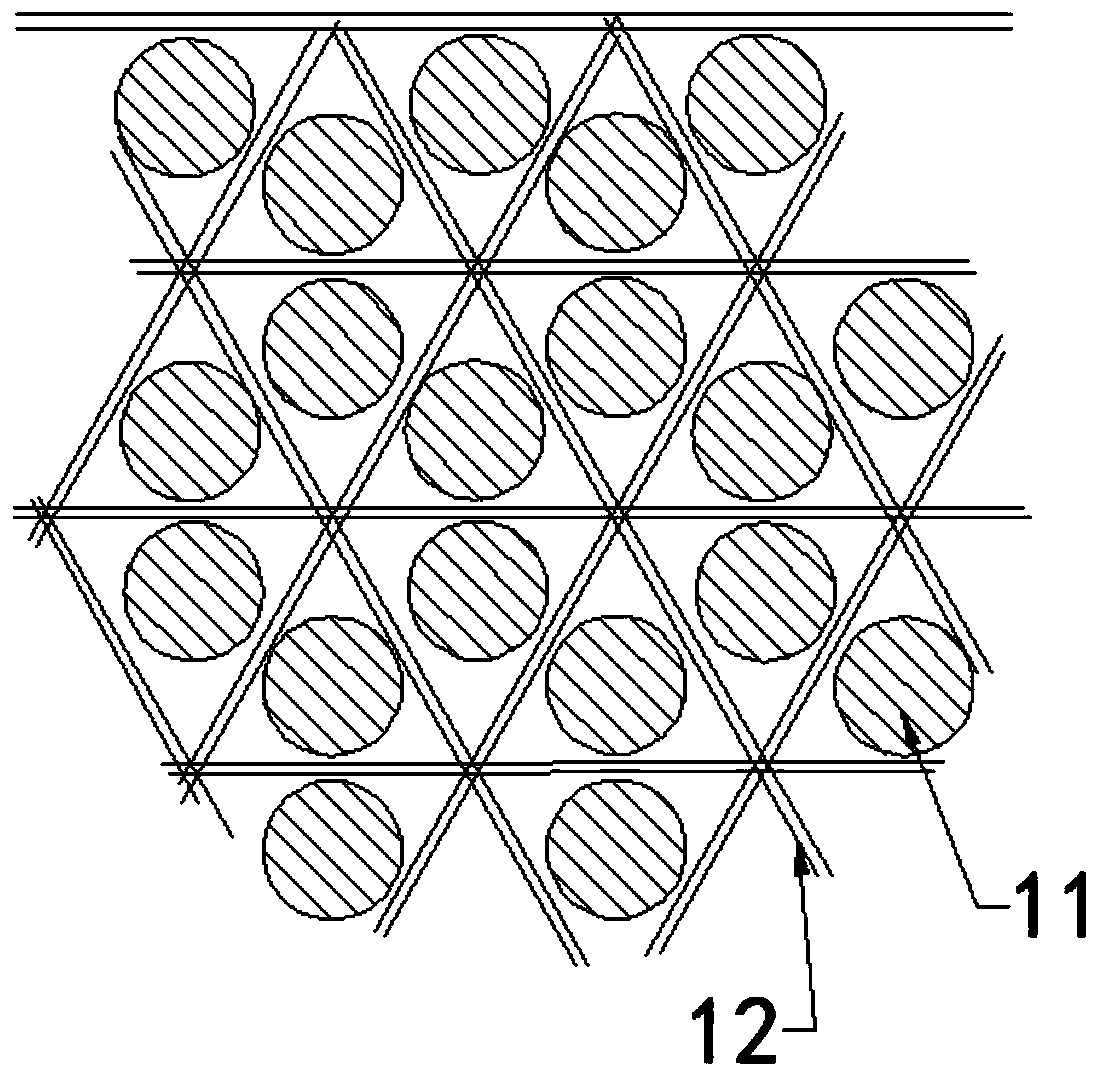

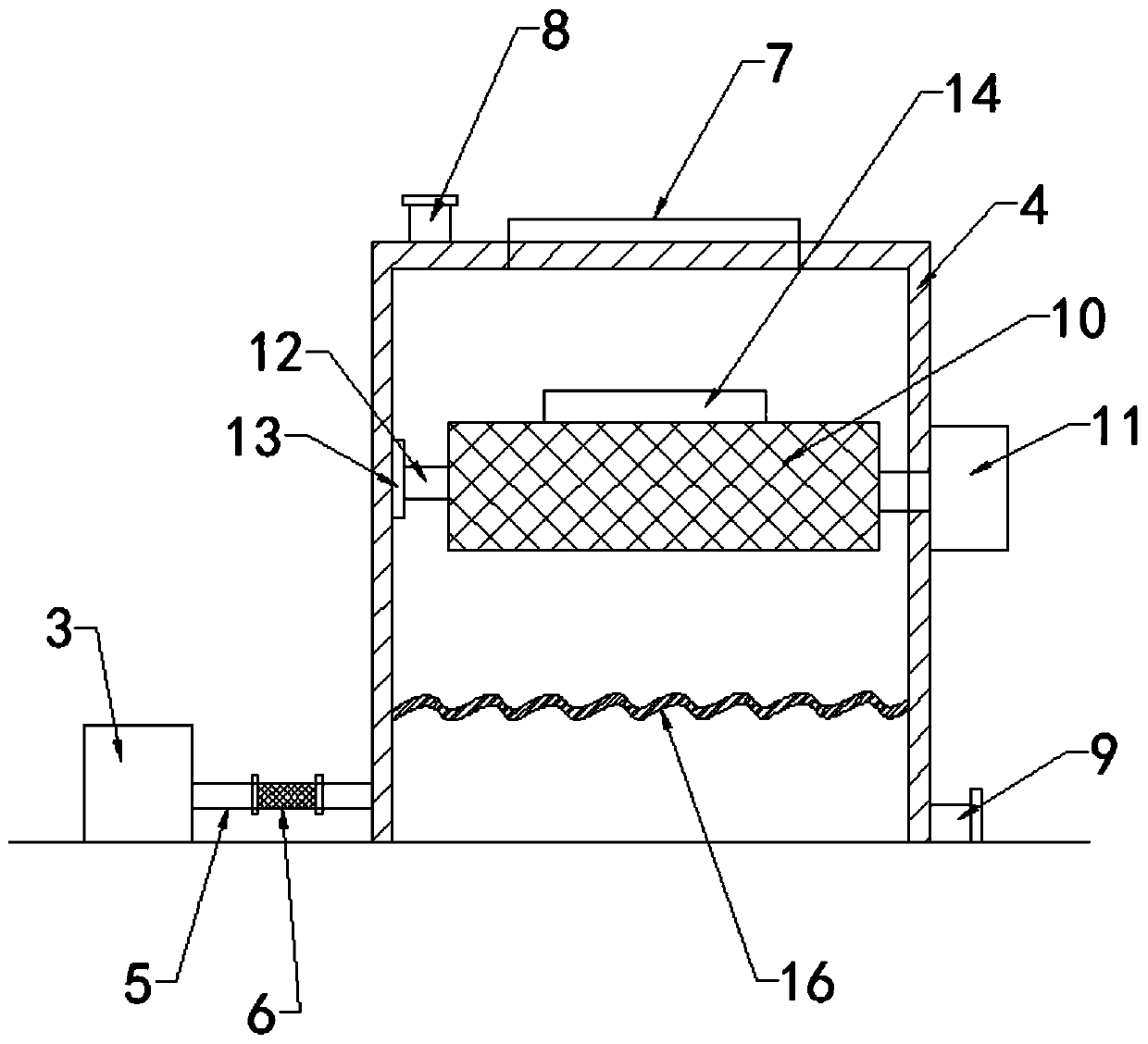

Embodiment 2

[0038] The basic principle of this embodiment is the same as that of Embodiment 1, the difference is: an electrolytic paper for lightning-resistant capacitors, which is composed of a pressure-resistant layer paper 1 and an absorption layer paper 2, and the pressure-resistant layer paper 1 wraps the Absorbing layer paper 2, the pressure-resistant layer paper 1 includes several tubular fiber units 11, the absorbent layer paper 2 is composed of a fine cellulose fiber non-woven fabric layer 21 and a hemp fiber layer 22, in this embodiment , the hemp fiber is selected from sisal, with a beating degree of 32 ° SR, made of sisal paddle, paper-making and drying, and a non-woven fabric of fine cellulose fibers formed by paper-making on the non-woven fabric layer. The fine cellulose fibers account for 90% of the weight of the fine cellulose fiber non-woven fabric, and the fine cellulose fiber non-woven fabric is dried and heat-treated after drying, and then the fine cellulose fiber non-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com