Surface metallization process of 5G antenna oscillator

An antenna vibrator and surface metal technology, which is applied in the field of mobile phone antenna preparation, can solve the problems of inconvenient product quality control, time-consuming, low efficiency, etc., so as to facilitate product quality control, simplify the metallization process, and avoid material waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

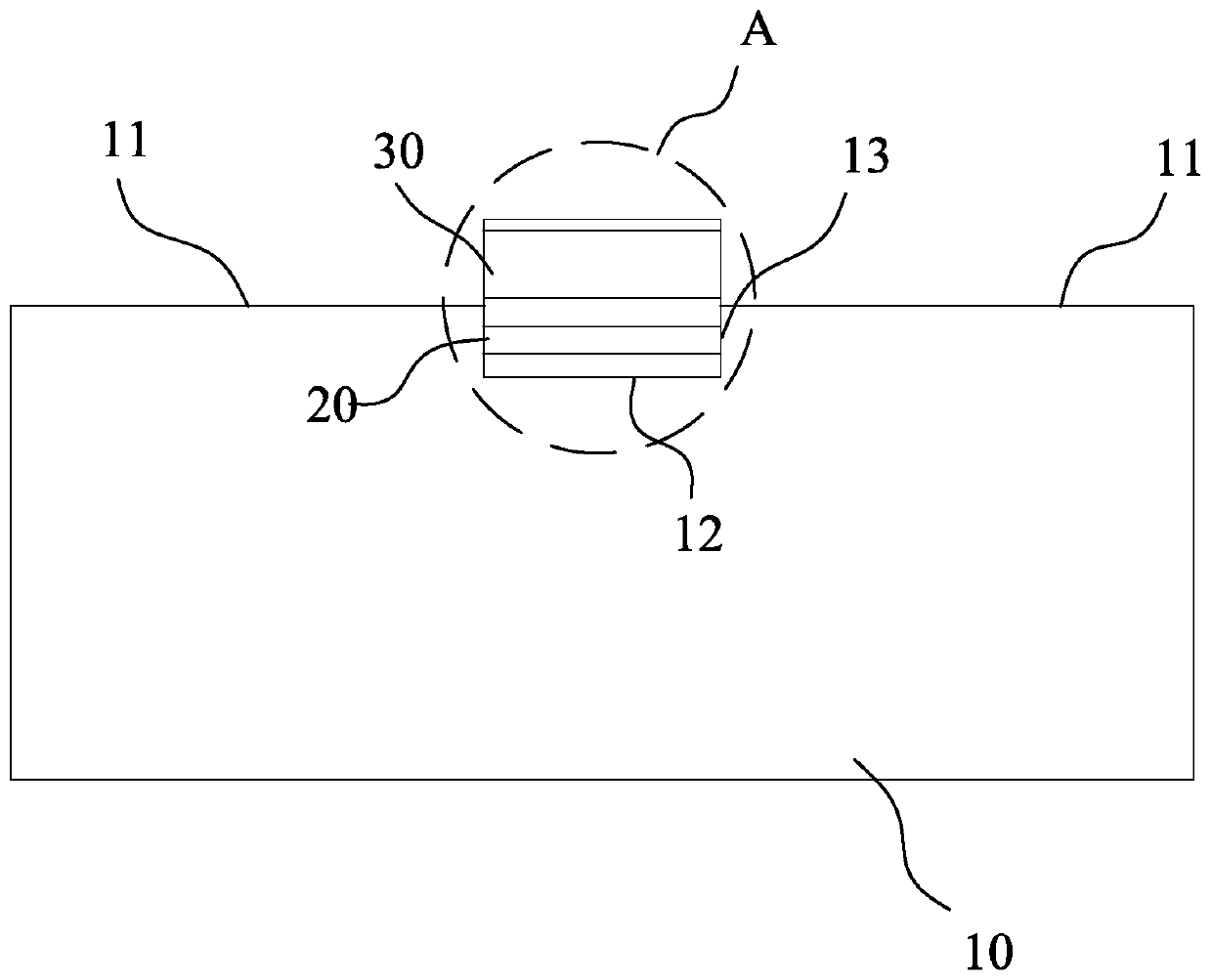

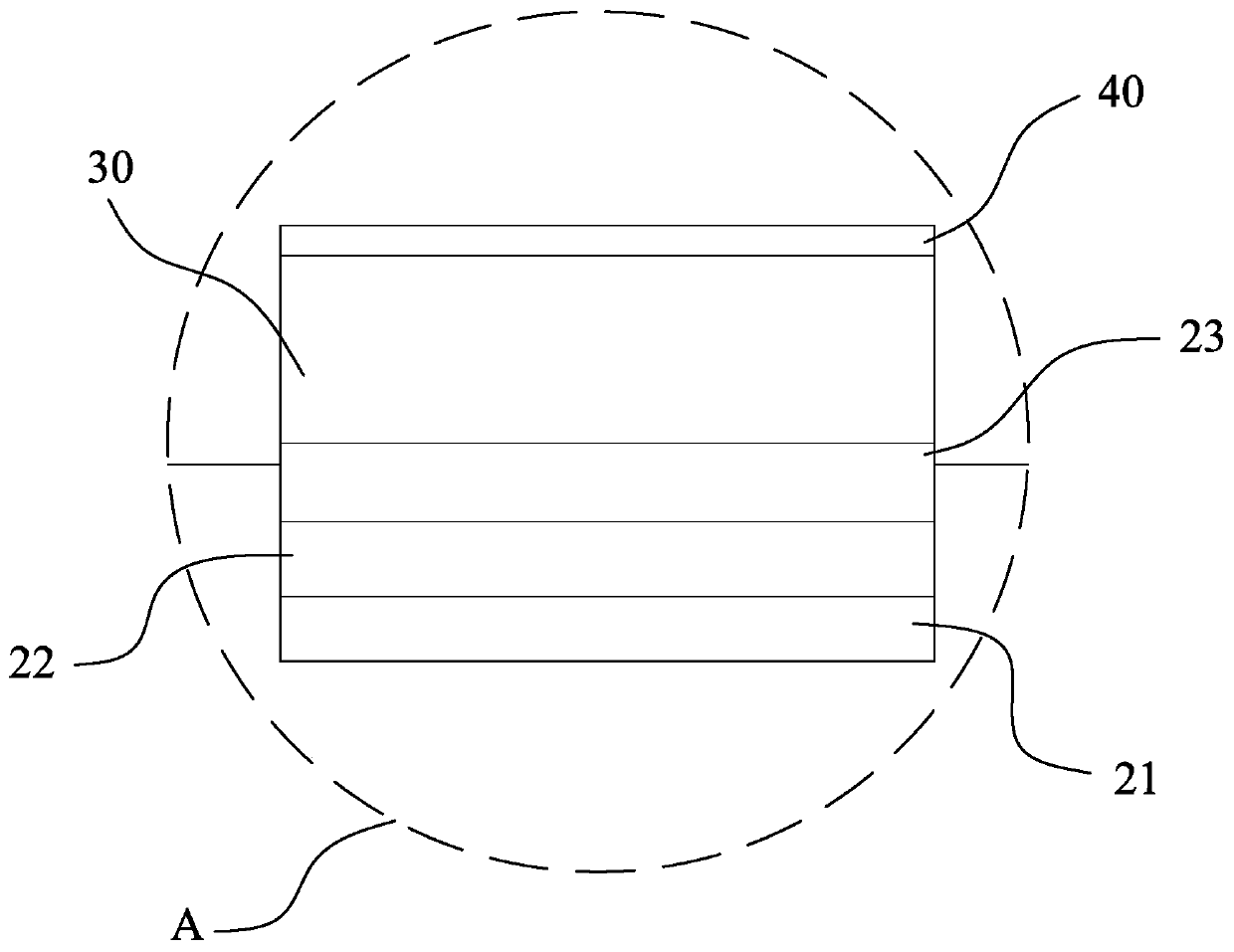

[0033] Embodiment 1 of the present invention, a 5G antenna vibrator surface metallization process, includes the following steps:

[0034] 1) A vibrator body with a predetermined structure is made by injection molding;

[0035] 2) Carry out radium engraving treatment on the electroplating area on the surface of the vibrator body, so that the metallized area on the surface of the vibrator body needs to be deeply activated by radium engraving to realize electroplating; when performing radium engraving treatment, the depth of radium engraving is 6 μm;

[0036] 3) Perform ultrasonic cleaning on the surface of the laser-engraved vibrator body;

[0037] 4) Perform copper electroplating treatment on the electroplating area on the surface of the vibrator body, and form a copper plating layer on the electroplating area on the surface of the vibrator body; specifically, when performing copper electroplating treatment, perform pre-copper plating and electroplating in the electroplating ar...

Embodiment 2

[0041] Embodiment 2 of the present invention, a 5G antenna vibrator surface metallization process, includes the following steps:

[0042] 1) A vibrator body with a predetermined structure is made by injection molding;

[0043] 2) Carry out radium engraving treatment on the electroplating area on the surface of the vibrator body, so that the metallized area on the surface of the vibrator body needs to be deeply activated by radium engraving to realize electroplating; when performing radium engraving treatment, the depth of radium engraving is 8 μm;

[0044] 3) Perform ultrasonic cleaning on the surface of the laser-engraved vibrator body;

[0045] 4) Perform copper electroplating treatment on the electroplating area on the surface of the vibrator body, and form a copper plating layer on the electroplating area on the surface of the vibrator body; specifically, when performing copper electroplating treatment, perform pre-copper plating and electroplating in the electroplating ar...

Embodiment 3

[0049] Embodiment 3 of the present invention, a 5G antenna vibrator surface metallization process, includes the following steps:

[0050] 1) A vibrator body with a predetermined structure is made by injection molding;

[0051] 2) Carry out laser engraving treatment on the electroplating area on the surface of the vibrator body, so that the metallized area on the surface of the vibrator body needs to be deeply activated by radium engraving to realize electroplating; when performing radium engraving treatment, the depth of radium engraving is 10 μm;

[0052] 3) Perform ultrasonic cleaning on the surface of the laser-engraved vibrator body;

[0053] 4) Perform copper electroplating treatment on the electroplating area on the surface of the vibrator body, and form a copper plating layer on the electroplating area on the surface of the vibrator body; specifically, when performing copper electroplating treatment, perform pre-copper plating and electroplating in the electroplating ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com