Modified carbon fiber reinforced polyamide 6 composite material for 3D printing, and preparation method and application thereof

A fiber reinforced, composite material technology, applied in the direction of additive processing, can solve the problems of uneven microscopic fiber dispersion, difficult to meet technical requirements, low dimensional accuracy, etc., and achieve excellent dimensional stability, excellent mechanical strength, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also discloses a preparation method of the above-mentioned modified carbon fiber reinforced polyamide 6 composite material, comprising the following steps:

[0037] (1) Drying: put polyamide 6 pellets into a constant temperature oven for drying to obtain dry moisture-free polyamide 6 pellets for later use; the drying method refers to that the drying temperature of the constant temperature oven is controlled at 80°C to 100°C In the range, the drying time is controlled between 6 hours and 9 hours. The preferred drying temperature is 90°C and the drying time is 8 hours.

[0038] (2) Carbon fiber modification: Dissolve the modified silane coupling agent in ethanol solution, and place the modified silane coupling agent solution and carbon fiber in an airtight container according to the formula amount. The airtight container usually uses a glass water tank to facilitate observation and fully react , and then pour out the remaining liquid, place it in an...

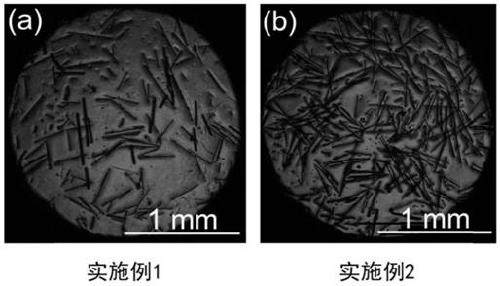

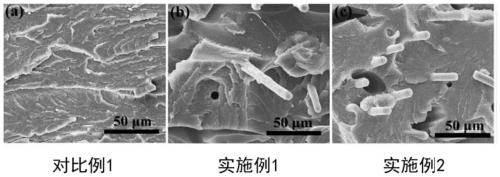

Embodiment 1

[0046] The invention provides a preparation method and application of a modified carbon fiber reinforced polyamide 6 composite material, which is composed according to the following weight percentages:

[0047] Weigh 95 parts of polyamide 6 (manufacturer: Tai-Young Nylon Co., Ltd.), 5 parts of carbon fiber tow (Toray, Japan), and 1 part of silane coupling agent (KH550, Shanghai Yaohua Chemical Factory), and the polyamide Amide 6 and carbon fiber tow were dried at 90° C. for 8 hours to obtain the first product;

[0048] Fully react the carbon fiber tow of the first product with the modified silane coupling agent solution in a glass tank for 24 hours, and form the second product with the polyamide 6 of the first product;

[0049] The second product is melted, blended, extruded and granulated by a twin-screw extruder to obtain the third product. The temperature of each section of the twin-screw extruder from the feed port to the discharge port is 235°C in the first zone, and 235°...

Embodiment 2

[0053] The invention provides a preparation method and application of a modified carbon fiber reinforced polyamide 6 composite material, which is composed according to the following weight percentages:

[0054] Weigh 90 parts of polyamide 6 (manufacturer: Tai-Young Nylon Co., Ltd.), 10 parts of carbon fiber tow (Toray Corporation of Japan), 2 parts of silane coupling agent (KH550, Shanghai Yaohua Chemical Factory), and the polyamide Amide 6 and carbon fiber tow were dried at 90° C. for 8 hours to obtain the first product;

[0055] Fully react the carbon fiber tow of the first product with the modified silane coupling agent solution in a glass tank for 24 hours, and form the second product with the polyamide 6 of the first product;

[0056] The second product is melted, blended, extruded and granulated by a twin-screw extruder to obtain the third product. The temperature of each section of the twin-screw extruder from the feed port to the discharge port is 235°C in the first zo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com