Preparation method of hexagonal boron nitride/polymer blocky composite material with high filling amount

A technology of hexagonal boron nitride and composite material, which is applied in the field of preparation of high-filling hexagonal boron nitride/polymer bulk composite material, and can solve the problem that the uniform filling density of hexagonal boron nitride cannot be efficiently improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

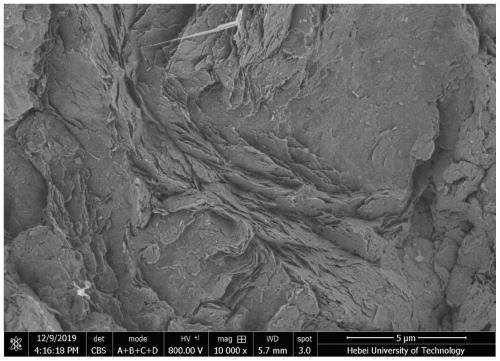

[0044] (1): 15g average lateral size is 700nm hexagonal boron nitride nanosheet-1, 4.32g bisphenol A epoxy resin, 3.67g methyltetrahydrophthalic anhydride (curing agent) and 0.08g 2,4,6- Tris(dimethylaminomethyl)phenol (catalyst) was added into an agate artificial mortar, ground and mixed evenly to obtain a hexagonal boron nitride nanosheet-epoxy resin mixture. Due to the low content of liquid substances, the mixed mixture was a wet powder status, illiquid;

[0045] (2): Put the hexagonal boron nitride nanosheet-epoxy resin mixture into the polytetrafluoroethylene ball mill jar in step (1), and mix evenly in the planetary ball mill, wherein the rotating speed of the ball mill is 500rpm, and the ball milling time is 600min, to obtain Mixed and reacted uniform hexagonal boron nitride nanosheet-epoxy resin mixture;

[0046] (3): Put the hexagonal boron nitride nanosheet-epoxy resin mixture mixed and reacted uniformly in step (2) into a cylindrical stainless steel metal mold with...

Embodiment 2、3、4、5、6、7

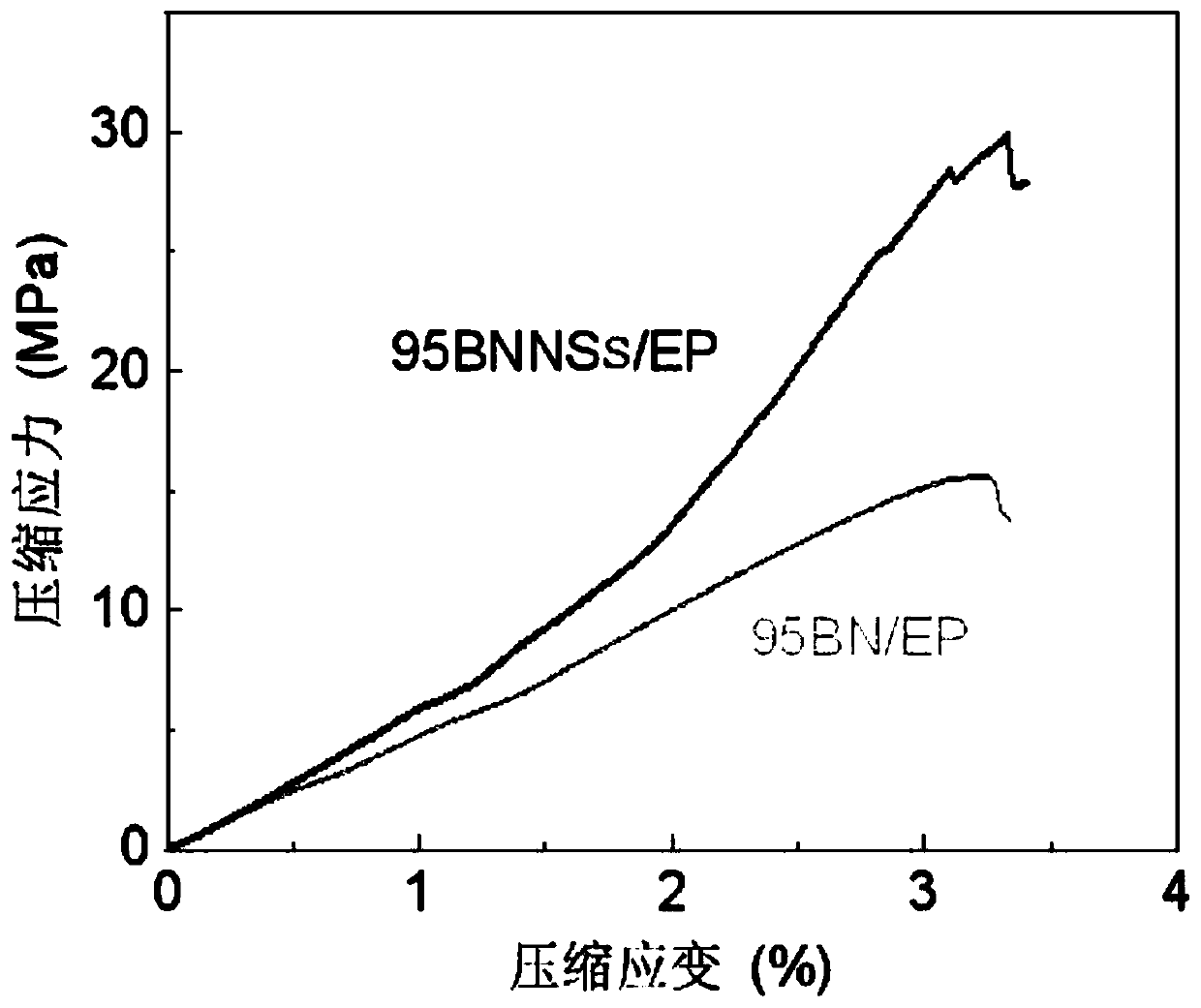

[0049] Change the amount of epoxy resin mixture in Example 1 step (1) so that the mass percentage of boron nitride nanosheets in the epoxy resin composite material is 70%, 75%, 80%, 85%, 90%, 95% , other operations are the same as in Example 1, named 70BNNSs / EP, 75BNNSs / EP, 80BNNSs / EP, 85BNNSs / EP, 90BNNSs / EP, 95BNNSs / EP respectively. The compressive strength of the composite material prepared by its embodiment 1 to 7 is as follows Figure 5 As shown, its compressive modulus is as Figure 6 shown.

Embodiment 8

[0051] (1): 10g average lateral size is 700nm hexagonal boron nitride nanosheet-1, 2.29g bisphenol A epoxy resin, 1.87g methyltetrahydrophthalic anhydride (curing agent) and 0.04g 2,4,6- Tris(dimethylaminomethyl)phenol (catalyst) was added into an agate artificial mortar, ground and mixed evenly to obtain a hexagonal boron nitride nanosheet-epoxy resin mixture. Due to the low content of liquid substances, the mixed mixture was a wet powder status, illiquid;

[0052] (2): Put the hexagonal boron nitride nanosheet-epoxy resin mixture into the polytetrafluoroethylene ball mill jar in step (1), and mix evenly in the planetary ball mill, wherein the rotating speed of the ball mill is 500rpm, and the ball milling time is 800min, to obtain Mixed and reacted uniform hexagonal boron nitride nanosheet-epoxy resin mixture;

[0053] (3): Putting the mixture in the step (2) into a cylindrical stainless steel metal mold with a diameter of 40mm, and applying a pressure of 60min by a piston ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com