A method for preparing dense polycrystalline diamond and a boron-doped polycrystalline diamond

A technology of polycrystalline diamond and boron doping, which is applied in the field of boron-doped polycrystalline diamond, can solve the problems of high price and unacceptable market, and achieve the effects of improving performance, reducing synthesis pressure and increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

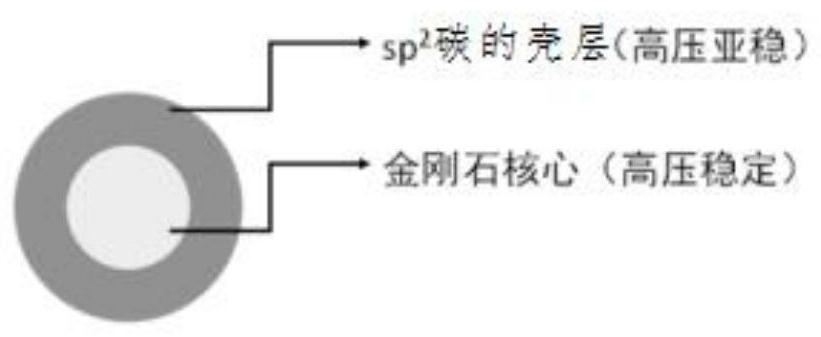

[0039] (1) Firstly, carbon nano-onions with diamond cores (particle size: 2-20nm) prepared from industrial detonation nano-diamonds by vacuum annealing (vacuum degree 1Pa, annealing temperature 1300°C, no heat preservation), mixed with mass The percentage is 3% (accounting for the sum of carbon nano-onions and elemental boron mass) elemental boron, which is uniformly mixed by ball milling under an inert environment;

[0040] (2) Utilize the hydraulic press to preliminarily pre-press the uniform mixture, with a pressure of 500 MPa and room temperature;

[0041] (3) The preliminary pre-pressed sample prepared in step (2) was pre-pressed twice under high pressure using a domestic six-sided top press, the molding pressure was 5GPa, and the temperature was 800°C to obtain a preform;

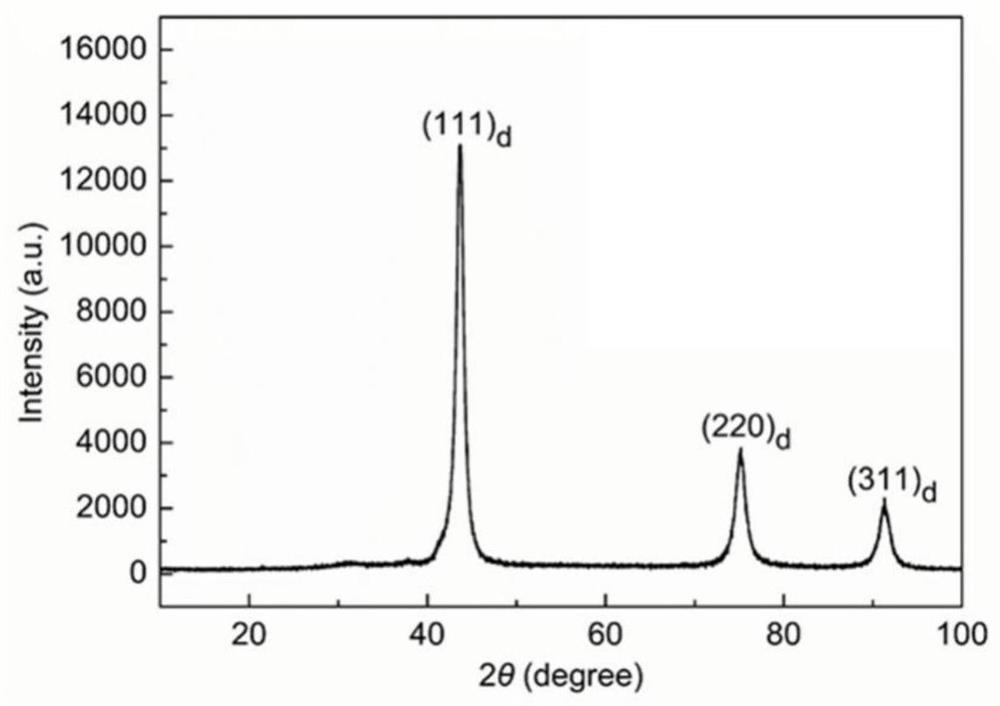

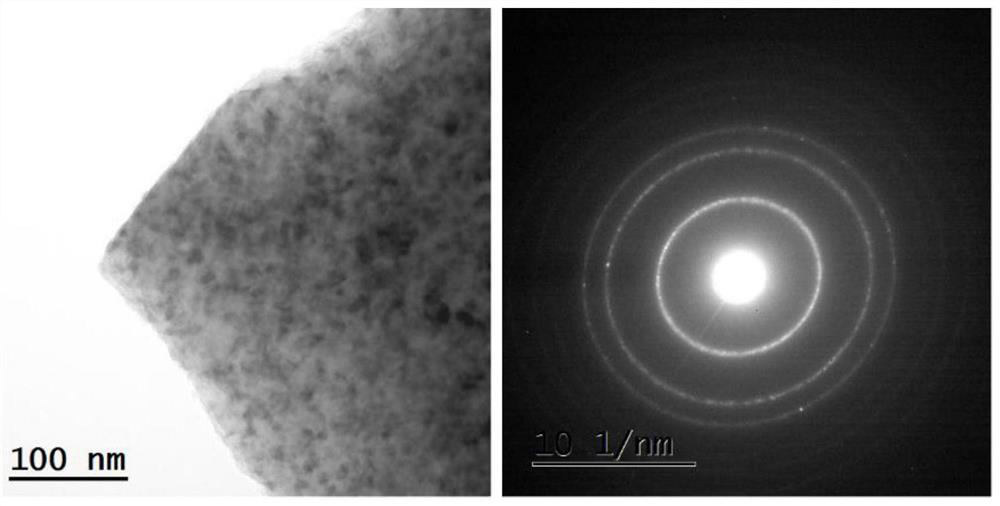

[0042] (4) Use the domestic six-sided roof to install the 6-8 multi-stage supercharging device to generate the preformed material obtained by high temperature and high pressure (8GPa and 1800°C); the ...

Embodiment 2

[0052] (1) First, the carbon nano-onions (the annealing conditions are the same as in Example 1, and the particle size is 2 to 20nm) prepared by industrial detonation nano-diamonds through vacuum annealing, the doping mass percentage is 1% ( Accounting for the sum of the mass of carbon nano-onions and elemental boron), the elemental boron is uniformly mixed by means of ball milling under an inert environment;

[0053] (2) Utilize the hydraulic press to preliminarily pre-press the uniform mixture, with a pressure of 500 MPa and room temperature;

[0054] (3) The preliminary pre-pressed sample prepared in step (2) was pre-pressed twice under high pressure using a domestic six-sided top press, and the molding pressure was 5GPa, and the temperature was 600°C to obtain a preform;

[0055] (4) Use the domestic six-sided roof to install the 6-8 multi-stage supercharging device to generate the preformed material obtained by high temperature and high pressure (10GPa and 2000°C); the hi...

Embodiment 3

[0063] (1) Firstly, the carbon nano-onions (the annealing conditions are the same as in Example 1, and the particle size is 2 to 20nm) prepared by industrial detonation nano-diamonds through vacuum annealing, the doping mass percentage is 10% ( Accounting for the sum of the mass of carbon nano-onions and elemental boron) elemental boron is uniformly mixed by means of ball milling under an inert environment;

[0064] (2) Utilize the hydraulic press to preliminarily pre-press the uniform mixture, with a pressure of 500 MPa and room temperature;

[0065] (3) The preliminary pre-pressed sample prepared in step (2) was pre-pressed twice under high pressure by using a domestic six-sided top press, with a molding pressure of 3GPa and a temperature of 600°C to obtain a preform;

[0066] (4) Preforms obtained by direct high-temperature and high-pressure treatment (5GPa and 1200°C) using domestic six-sided roof; Raise the temperature to 1200°C at a heating rate of 1,200°C, hold the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com