Production method of chromium corundum brick with reduction reaction resistance and thermal shock resistance for non-ferrous metal smelting fuming furnace or side-blown furnace

A non-ferrous metal, chrome corundum brick technology, applied in the field of refractory materials, can solve the problems of poor anti-reduction reaction and thermal shock stability, unable to meet the requirements of kiln use, etc., to improve anti-stripping performance, good anti-reduction effect, iron oxide low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

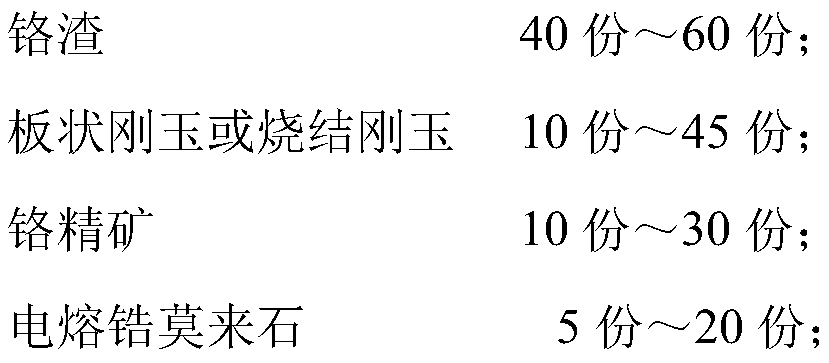

Method used

Image

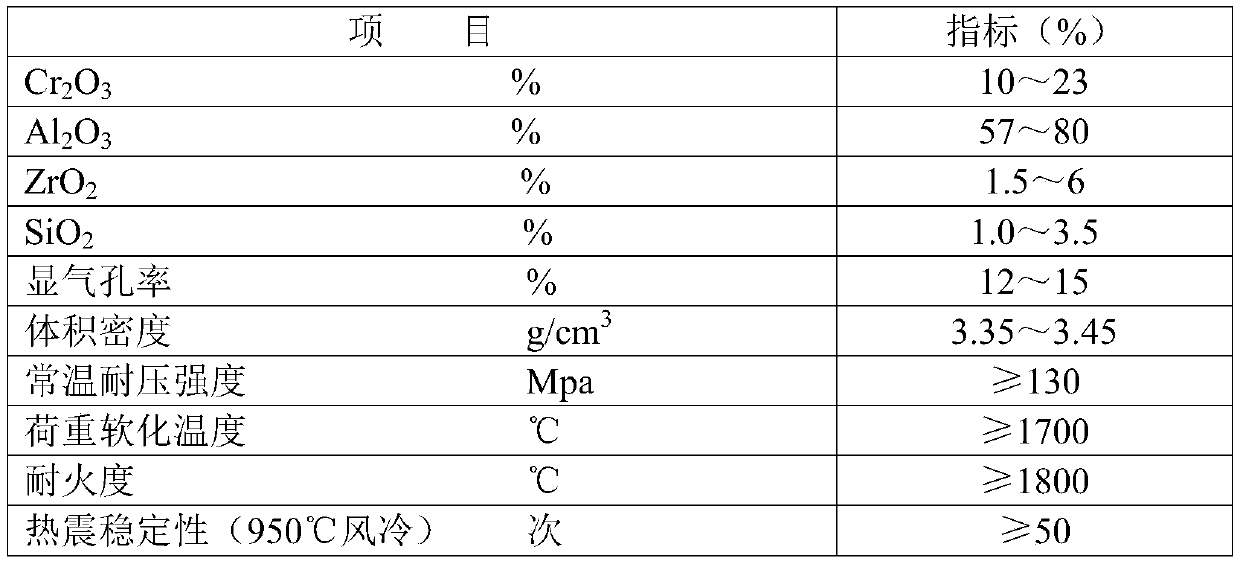

Examples

Embodiment 1

[0036] Raw material selection: Al in chromium slag 2 o 3 The mass percentage content is 78% ~ 86%, Cr 2 o 3 The mass percentage content is 5% ~ 13%, Al 2 o 3 and Cr 2 o 3 The mass percentage content of the total amount is ≥92%; Al in the tabular alumina 2 o 3 Mass percentage content ≥ 99.0%; Al in the chrome concentrate 2 o 3 The mass percentage content is 15% to 26%, Cr 2 o 3 The mass percentage content is 43% to 56%; the Al in the fused zircon mullite 2 o 3 Mass percentage content 43% ~ 48%, SiO 2 Mass percentage content 16% ~ 20%, ZrO 2 Mass percentage content ≥ 30.0%.

[0037] Concrete preparation steps are as follows:

[0038] a. Raw materials and processing

[0039] Crushing the chromium slag to a particle size of ≤5mm; crushing the tabular alumina to a particle size of ≤5mm; grinding the chrome concentrate to a particle size of 40 mesh; crushing the fused zirconia mullite to a particle size of ≤3mm;

[0040] b. Mix well

[0041] Mix 8.4 tons of chromi...

Embodiment 2

[0053] Raw material selection: Al in chromium slag 2 o 3 The mass percentage content is 78% ~ 86%, Cr 2 o 3 The mass percentage content is 5% ~ 13%, Al 2 o 3 and Cr 2 o 3 The mass percentage content of the total amount is ≥92%; Al in the sintered corundum 2 o 3 Mass percentage content ≥ 99.0%; Al in the chrome concentrate 2 o 3 The mass percentage content is 15% to 26%, Cr 2 o 3 The mass percentage content is 43% to 56%; the Al in the fused zircon mullite 2 o 3 Mass percentage content 43% ~ 48%, SiO 2 Mass percentage content 16% ~ 20%, ZrO 2 Mass percentage content ≥ 30.0%.

[0054] Concrete preparation steps are as follows:

[0055] a. Raw materials and processing

[0056] Crushing chromium slag to particle size ≤ 5mm; crushing sintered corundum to particle size ≤ 5mm; grinding chrome concentrate to particle size 40 mesh; crushing fused zirconia mullite to ≤ 3mm;

[0057] b. Mix well

[0058] Mix 15 tons of chromium slag crushed to a particle size of ≤5 mm,...

Embodiment 3

[0070] Raw material selection: Al in chromium slag 2 o 3 The mass percentage content is 78% ~ 86%, Cr 2 o 3 The mass percentage content is 5% ~ 13%, Al 2 o 3 and Cr 2 o 3 The mass percentage content of the total amount is ≥92%; Al in the sintered corundum 2 o 3 Mass percentage content ≥ 99.0%; Al in the chrome concentrate 2 o 3 The mass percentage content is 15% to 26%, Cr 2 o 3 The mass percentage content is 43% to 56%; the Al in the fused zircon mullite 2 o 3 Mass percentage content 43% ~ 48%, SiO 2 Mass percentage content 16% ~ 20%, ZrO 2 Mass percentage content ≥ 30.0%.

[0071] Concrete preparation steps are as follows:

[0072] a. Raw materials and processing

[0073] Crushing the chromium slag to a particle size of ≤5mm; crushing the tabular alumina to a particle size of ≤5mm; grinding the chrome concentrate to a particle size of 40 mesh; crushing the fused zirconia mullite to a particle size of ≤3mm;

[0074] b. Mix well

[0075] 11.1 tons of chromiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com