Metal flat tube supporting body, battery/electrolytic cell and battery stack structure

A support body and electrolytic cell technology, applied in the field of battery stack structure and metal flat tube support body, can solve problems such as poor sealing performance, and achieve the effects of preventing gas leakage, reducing manufacturing costs, and preventing gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

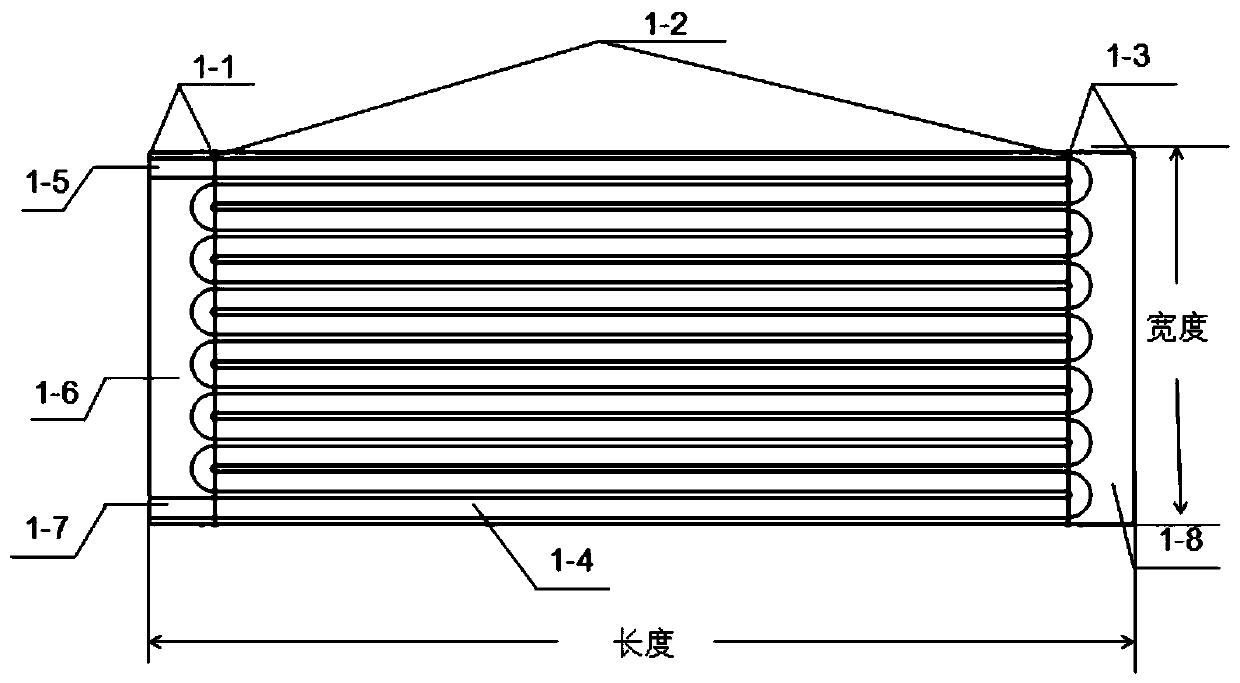

Embodiment 1

[0078] see figure 1 As shown, in this embodiment, iron-nickel alloy is used as the metal flat tube support body material, and the metal flat tube support body is formed by powder metallurgy sintering. : 15cm * 5cm, the middle section of the flat tube is porous, the porosity is 30%, the two ends are dense, and the inside has a serpentine gas flow channel, wherein, 1 cm of the blind hole end of the flat tube (that is, the closed end in the present invention) is a dense area , the 2cm at the end of the opening is a dense area, and the middle 12cm is a porous structure. The Ni / GDC anode was prepared by atmospheric plasma spraying on the porous structure of the metal support, covering the porous structure, the ScSZ electrolyte was prepared by atmospheric plasma spraying, the anode was completely wrapped, and the LSCF cathode was prepared on the electrolyte by atmospheric plasma spraying to complete the preparation of the single cell.

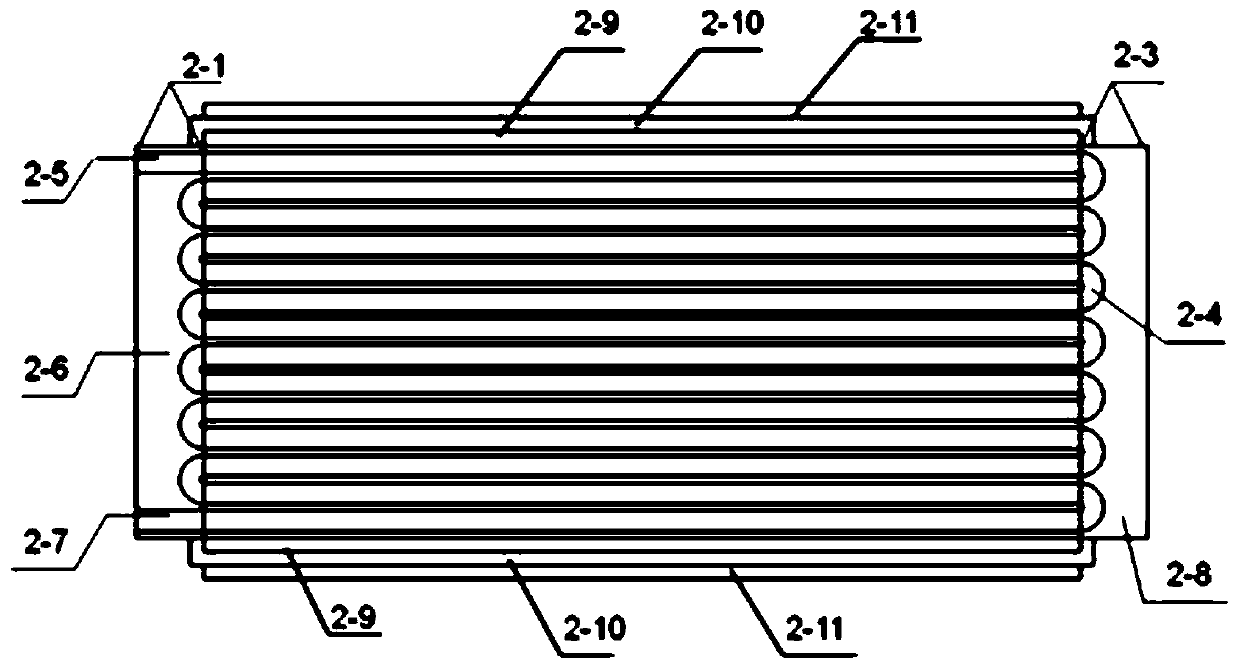

Embodiment 2

[0080] In this embodiment, pure chromium is used as the metal flat tube support material, and the metal flat tube support is prepared by powder metallurgy. The thickness of the flat tube is 1.2 cm, and the length and width of the upper and lower plane areas are 6 cm and 24 cm respectively. 15%, both ends are dense, and there is a gas flow channel inside the flat tube. Among them, the 1cm of the blind hole end of the flat tube is a dense area, and the 3cm of the open section is a dense area. The middle 20cm is a porous structure, and the sprayed Ni / GDC cathode wraps the middle porous support body, spray BZCY electrolyte to wrap the cathode and all exposed porous metal supports, screen-print LSM anodes on the two planes of the flat tube, and prepare an electrolytic cell after sintering. The prepared electrolytic cell exhibits a high hydrogen production rate.

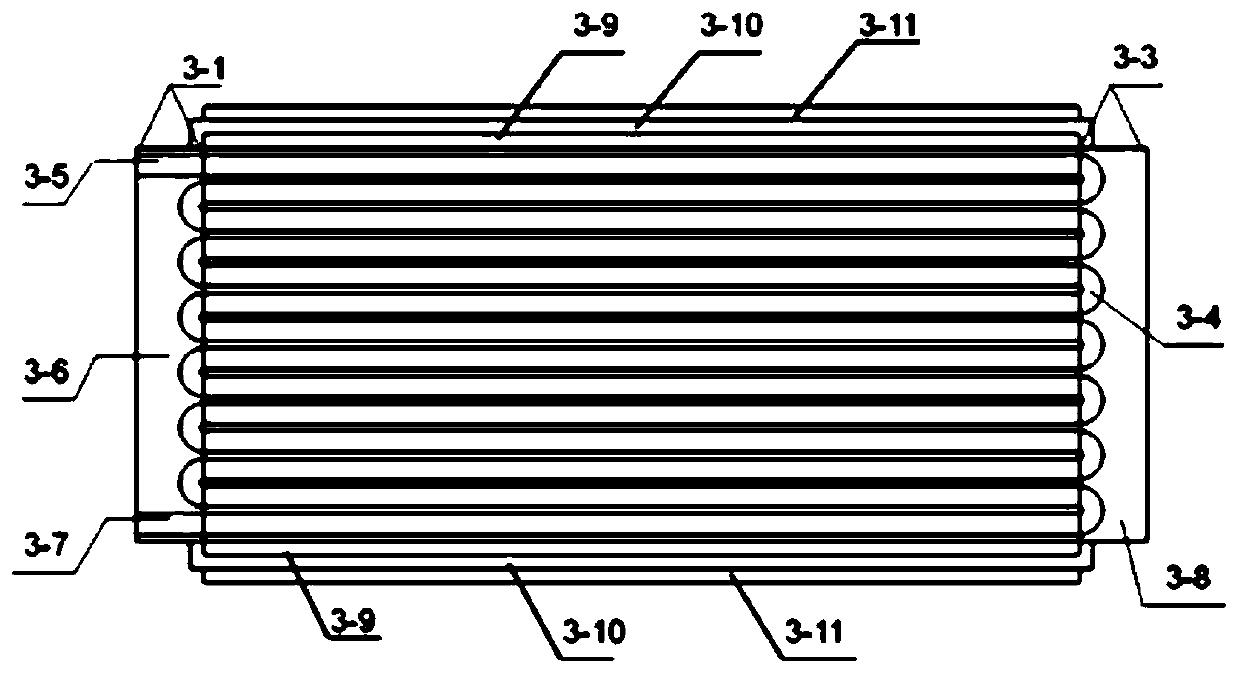

Embodiment 3

[0082] In this embodiment, iron-nickel alloy is used as the metal flat tube support body material, and the metal flat tube support body is formed by powder metallurgy sintering. A flat tube metal support body, wherein the 1 cm at both ends is a dense area, and the middle 28 cm is a porous structure with a porosity of 40%. The Ni / GDC anode was prepared by atmospheric plasma spraying on the porous structure of the metal support, covering the porous structure, the ScSZ electrolyte was prepared by vacuum plasma spraying, and the anode was completely wrapped, and the LSCF cathode was prepared by atmospheric plasma spraying on the electrolyte, and two porous metal sheets were Contact the cathodes on both sides of the flat tube through the elastic force to derive the current on the cathode side to complete the preparation of the single cell. Single cell expresses good voltage and power output.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com