High-impact interface modified CF/PEEK composite material and preparation method thereof

A composite material, high impact technology, applied in the field of carbon fiber reinforced polyether ether ketone composite material, can solve the problems of difficult to achieve industrialized production and small improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation method of the CF / PEEK composite material of high-impact interface modification, the steps are as follows:

[0050] (1) Sinter 3K5 satin fabrics of CF T300 grade at 300°C for 180 minutes to decompose the original sizing agent on the surface;

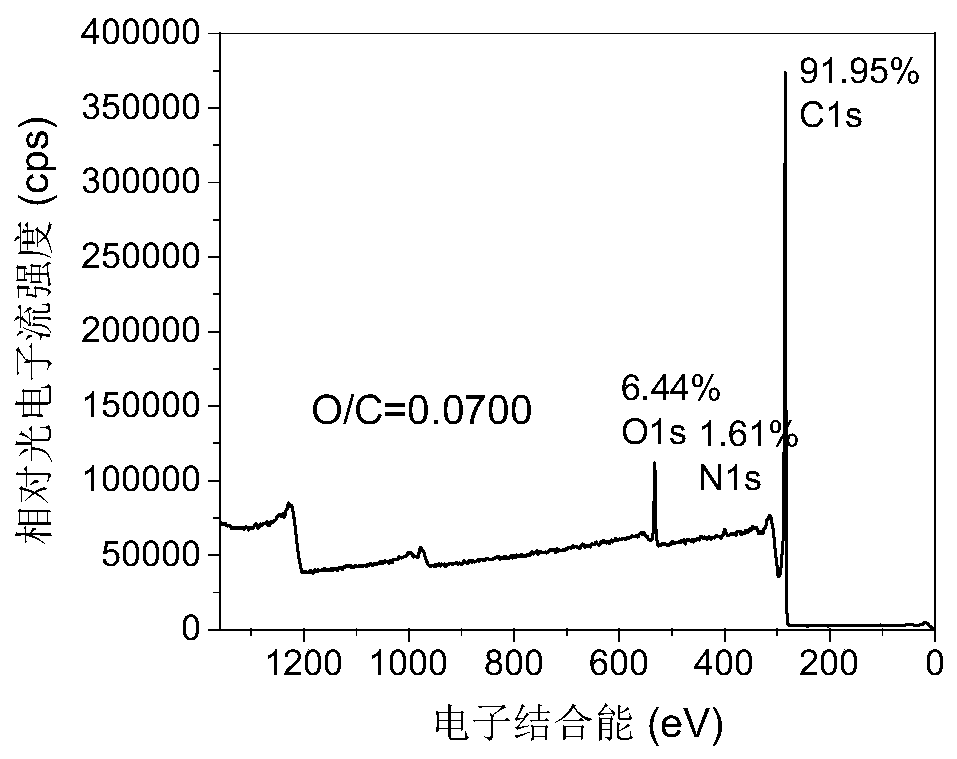

[0051] (2) In a saturated water vapor environment with a relative humidity of 95.3%, microwave irradiation and ultraviolet light irradiation are carried out on CF simultaneously, and the product is recorded as ACF; the time of microwave irradiation is 30min, and the microwave frequency is 300MHz; the wavelength of ultraviolet light is irradiated 290nm, UV irradiance is 20W / m 2 ;

[0052] (3) Immerse the ACF in a polyarylsulfone / N,N-dimethylacetamide solution with a concentration of 0.2wt.% for 120min. The weight-average molecular weight of the polyarylsulfone is 56000, take it out and dry it until the water content is 0.48wt. %, to obtain sizing modified carbon fiber MCF;

[0053] (4) MCF and PEEK powder with a w...

Embodiment 2

[0072] The preparation method of the CF / PEEK composite material of high-impact interface modification, the steps are as follows:

[0073] (1) Sinter 3K5 satin fabrics of CF T300 grade at 350°C for 138min to decompose the original sizing agent on the surface;

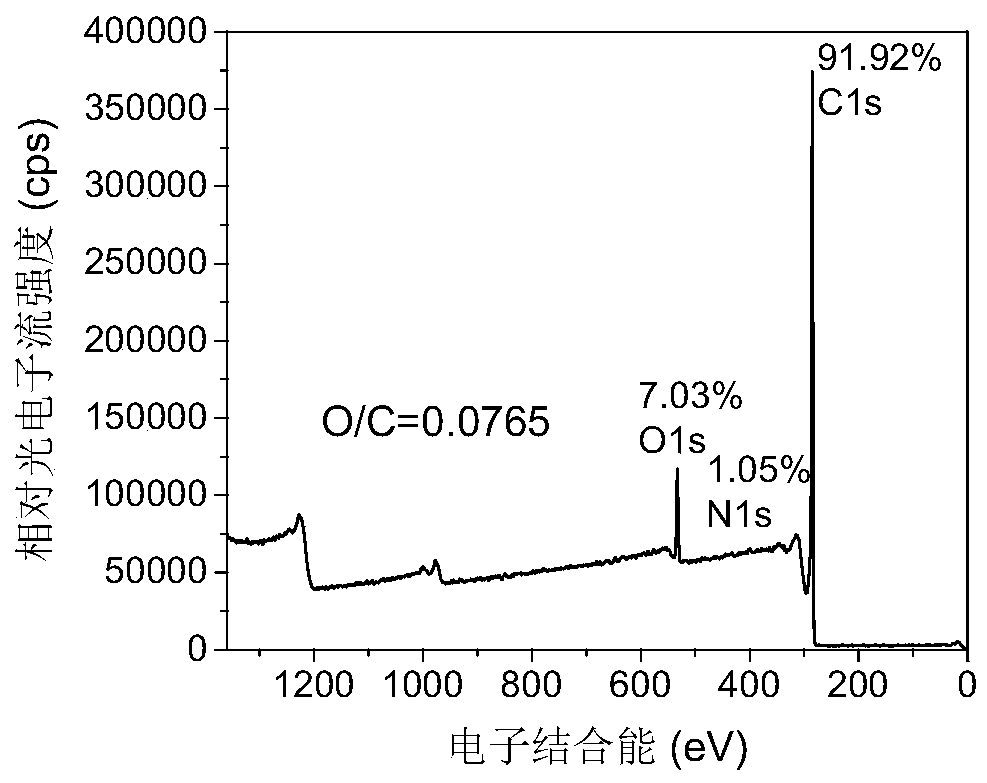

[0074] (2) In a saturated water vapor environment with a relative humidity of 95.8%, CF is irradiated with microwaves and ultraviolet light at the same time, and the product is recorded as ACF; the time of microwave irradiation is 27min, and the microwave frequency is 820MHz; the wavelength of ultraviolet light is irradiated 299nm, UV irradiance is 50W / m 2 ;

[0075] (3) Immerse the ACF in a polyarylsulfone / N,N-dimethylacetamide solution with a concentration of 0.8wt.% for 115min. The weight-average molecular weight of the polyarylsulfone is 58000, take it out and dry it to a water content of 0.45wt. %, to obtain sizing modified carbon fiber MCF;

[0076] (4) MCF and PEEK powder with a weight-average molecular weight ...

Embodiment 3

[0080] The preparation method of the CF / PEEK composite material of high-impact interface modification, the steps are as follows:

[0081] (1) Sinter 5 pieces of satin fabric of T300 grade 3K of CF at 420°C for 5 minutes to decompose the original sizing agent on the surface;

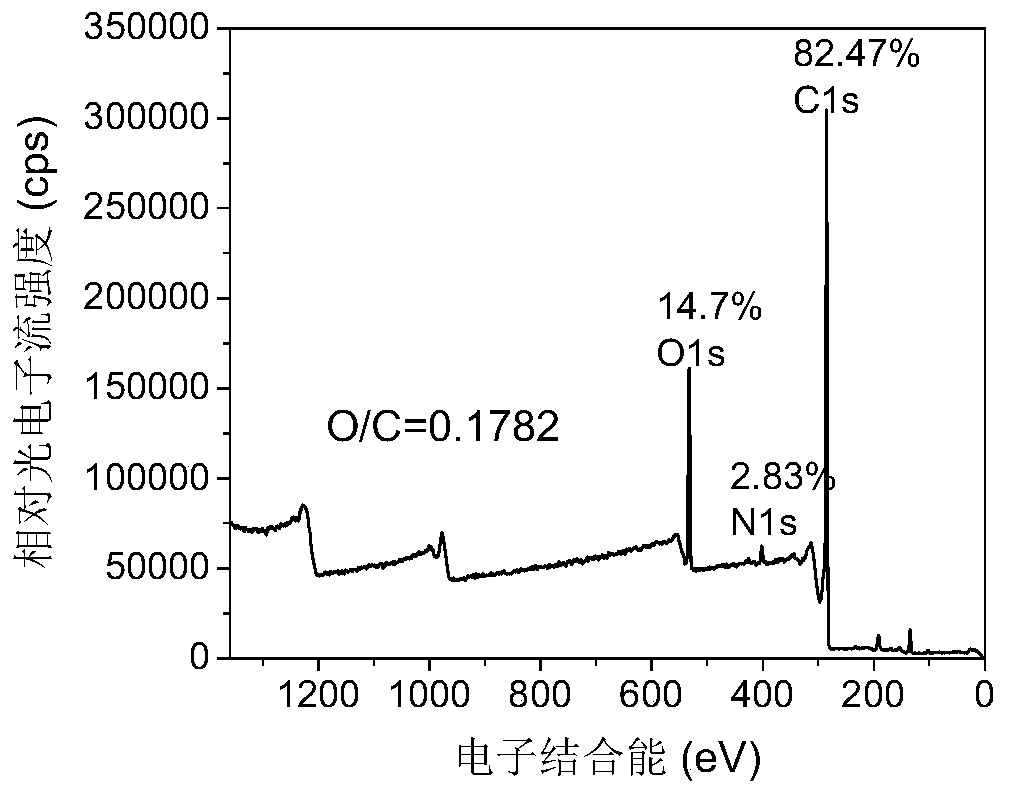

[0082] (2) In a saturated water vapor environment with a relative humidity of 95.9%, CF is irradiated with microwaves and ultraviolet light at the same time, and the product is denoted as ACF; the time of microwave irradiation is 24min, and the microwave frequency is 1GHz; the wavelength of ultraviolet light is irradiated 305nm, UV irradiance is 35W / m 2 ;

[0083] (3) Immerse the ACF in a polyarylsulfone / N,N-dimethylacetamide solution with a concentration of 1.2wt.% for 94min. The weight-average molecular weight of the polyarylsulfone is 59100, take it out and dry it to a water content of 0.42wt. %, to obtain sizing modified carbon fiber MCF;

[0084] (4) MCF and PEEK non-woven felt with a weight-avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com