Monocrystalline silicon wafer texturing agent and texturing method using texturing agent

A single crystal silicon wafer and texturing agent technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of increasing production cost, high reaction temperature, long reaction time, etc., to increase production The effect of productivity, lower reaction temperature and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

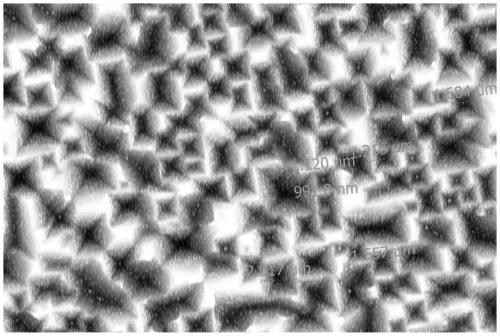

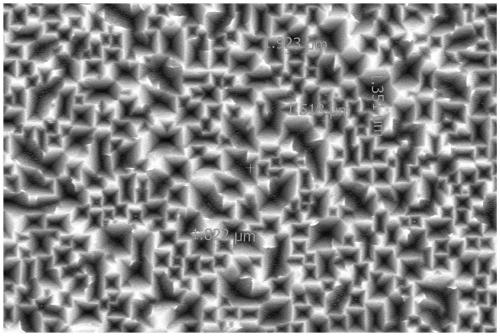

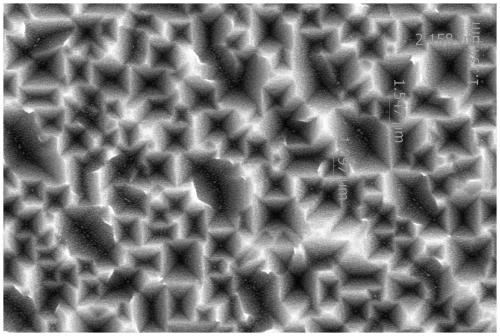

Image

Examples

Embodiment 1

[0037] Prepare the initiator: mix 10 parts of HF with a concentration of 49% and 1 part of the glass component, soak at room temperature for more than 24 hours, filter to remove insoluble matter, and obtain the initiator.

[0038] Preparation of the regulating agent: 51.5 parts of copper nitrate hydrate, 4 parts of 1% nitric acid and 44.5 parts of deionized water were mixed and stirred for 30 minutes, and then dissolved to obtain the regulating agent.

[0039] Preparation of the first texturing agent: In 125L deionized water, add 36.72L of 49% HF and 16.44L of 31% H 2 o 2 , 1.2L regulator and 0.8L initiator, stirred at room temperature for 30 minutes and mixed uniformly to obtain 180.16L of the first texturing agent.

[0040] Preparation of the second texturing agent: In 119L deionized water, add 26.20L of 49%HF and 18L of 31%H 2 o 2 , 6L regulating agent and 0.8L initiator, stirred at room temperature for 30 minutes and mixed uniformly to obtain 170L second texturizing age...

Embodiment 2

[0043] Prepare the initiator: mix 10 parts of HF with a concentration of 49% and 1 part of the glass component, soak at room temperature for more than 24 hours, filter to remove insoluble matter, and obtain the initiator.

[0044] Preparation of the regulating agent: 51.5 parts of copper nitrate hydrate, 4 parts of 1% nitric acid and 44.5 parts of deionized water were mixed and stirred for 30 minutes, and then dissolved to obtain the regulating agent.

[0045] Preparation of the first texturing agent: in 126L of deionized water, add 36.72L of 49% HF and 15.24L of 31% H 2 o 2 , 1.2L regulator and 0.8L initiator, stirred at room temperature for 30 minutes and mixed uniformly to obtain 179.96L of the first texturing agent.

[0046] Preparation of the second texturing agent: In 118L deionized water, add 26.20L of 49%HF and 19.2L of 31%H 2 o 2 , 6L regulator and 0.8L initiator, stirred at room temperature for 30 minutes and mixed uniformly to obtain 170.2L of the second texturin...

Embodiment 3

[0049] Prepare the initiator: mix 10 parts of HF with a concentration of 49% and 1 part of the glass component, soak at room temperature for more than 24 hours, filter to remove insoluble matter, and obtain the initiator.

[0050] Preparation of the regulating agent: 51.5 parts of copper nitrate hydrate, 4 parts of 1% nitric acid and 44.5 parts of deionized water were mixed and stirred for 30 minutes, and then dissolved to obtain the regulating agent.

[0051] Preparation of the first texturing agent: In 125L deionized water, add 36.72L of 49% HF and 16.44L of 31% H 2 o 2 , 1.2L regulator and 0.8L initiator, stirred at room temperature for 30 minutes and mixed uniformly to obtain 180.16L of the first texturing agent.

[0052] Preparation of the second texturing agent: In 118L deionized water, add 26.20L of 49%HF and 19.2L of 31%H 2 o 2 , 6L regulator and 0.8L initiator, stirred at room temperature for 30 minutes and mixed uniformly to obtain 170.2L of the second texturing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com