Lanthanum-based loaded magnetic nano-adsorption phosphorus removal material and its synthesis method

A synthesis method, magnetic nanotechnology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as odor generation, dissolved oxygen consumption, and biodiversity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

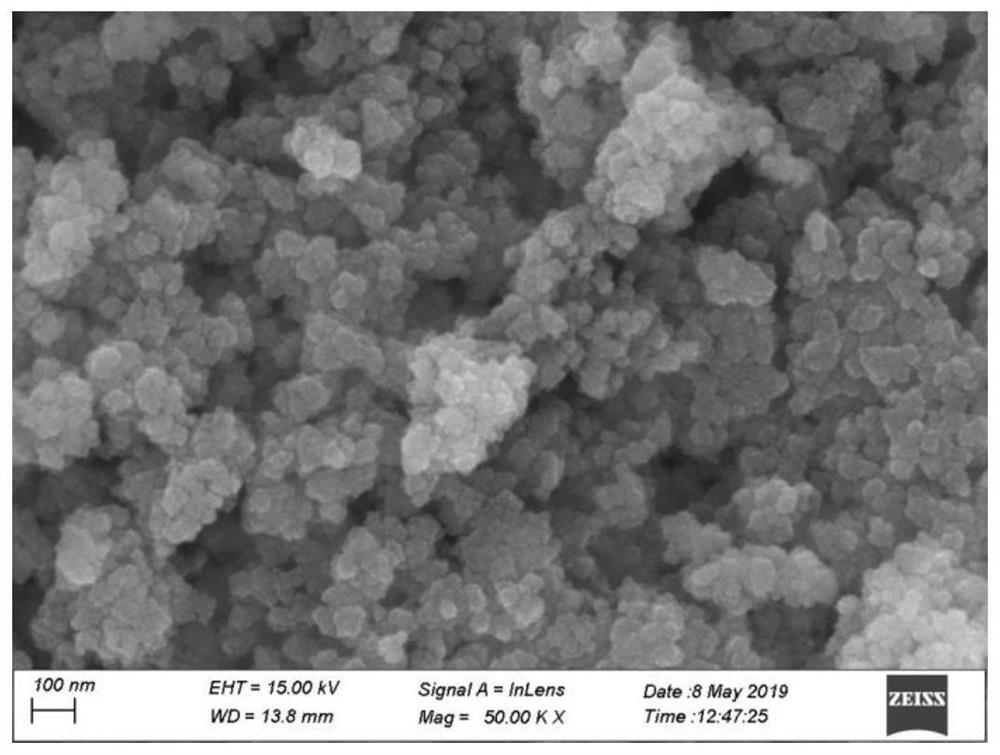

[0035] Preparation of Fe3O4

[0036] Concretely include the following steps: first, put the deionized water in a vacuum device for 0.5h to remove the oxygen in the water; In the three-necked flask, the temperature was raised to 60°C under the protection of nitrogen; 52mL of 4mol / L NaOH solution was added dropwise into the three-necked flask within 30min, and mechanically stirred at 400rpm at the same time, so that the pH of the solution rose to 9-10; 500rpm mechanically stirred for 1h, The final product is magnetically separated, washed twice with ethanol and water respectively, freeze-dried by a freeze dryer, and stored in a vacuum oven for later use. The grain size distribution of the iron ferric oxide prepared by the method is 5-50nm.

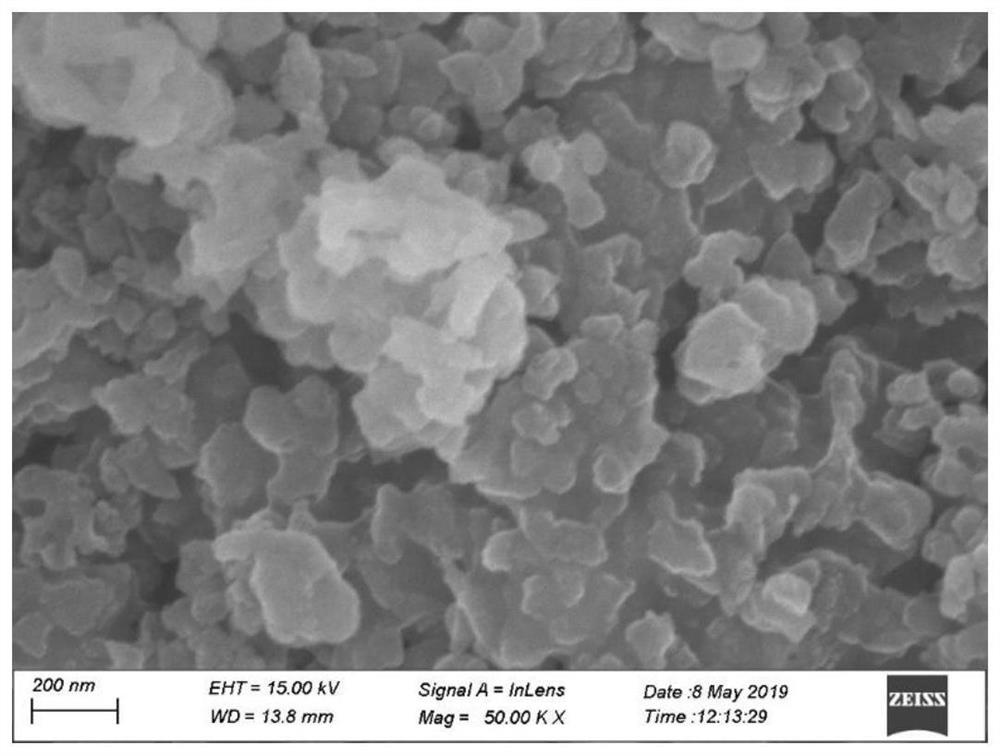

[0037] 1. Preparation of materials for adsorption and phosphorus removal

Embodiment 1

[0039] Weigh 5mmol ferric oxide and add it into 80ml pure water for 15min; then add 6.0g sodium citrate and stir mechanically for 30min; then add 20mmol lanthanum chloride and stir mechanically for 30min, 1000r / min; then seal it in the polytetrafluoroethylene-lined Stainless steel autoclave. Heated at 180°C for 12h and cooled to room temperature. After magnetic separation, the product is washed several times with pure water and ethanol, and vacuum freeze-dried to obtain the magnetic lanthanum-based phosphorus removal adsorption material.

Embodiment 2

[0041] Weigh 5mmol of ferric oxide and add it to 80ml of ethanol and sonicate for 15min; then add 6.0g of sodium ethylenediaminetetraacetate and stir mechanically for 30min; then add 5mmol of lanthanum chloride and stir mechanically for 60min at 500r / min; Lined stainless steel autoclave. Heated at 200°C for 10h and cooled to room temperature. After filtration and separation, the product is washed several times with pure water and ethanol, and vacuum freeze-dried to obtain the magnetic lanthanum-based phosphorus removal adsorption material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com