Composite conductive adhesive suitable for silicon-based negative electrode of lithium ion battery

A conductive adhesive, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of lack of electrical conductivity and low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

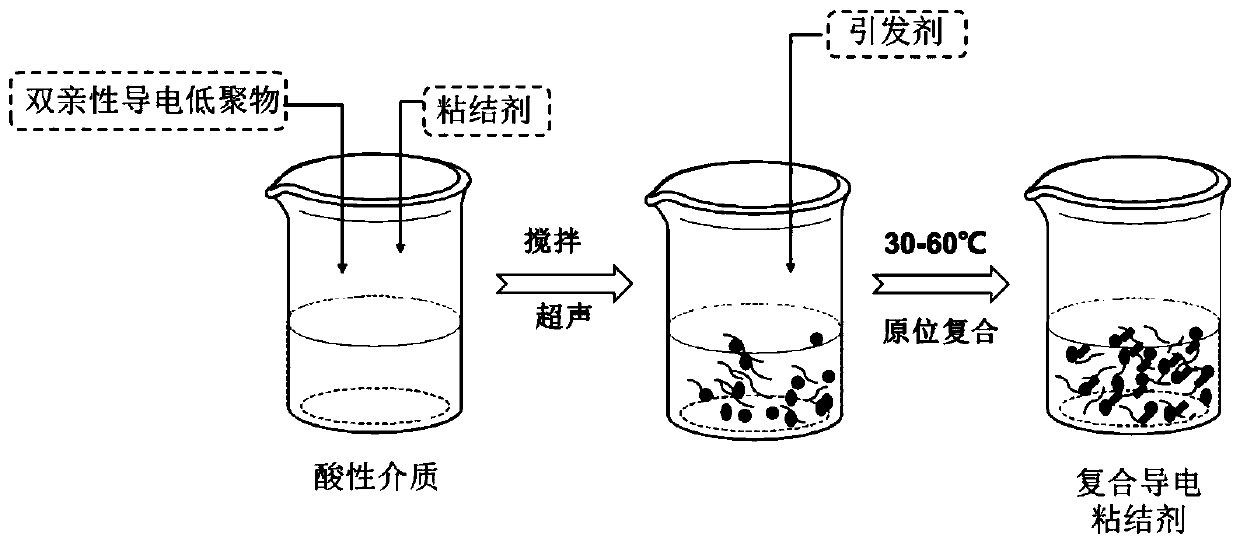

Method used

Image

Examples

Embodiment 1

[0042] (1) Add 10g of N-bromoacetanilide tetramer and 300ml of 7M hydrochloric acid into a three-necked flask, ultrasonicate for 20min, and mix well;

[0043] (2) Add 40g of 30wt% polyvinyl alcohol aqueous solution into a three-necked flask, stir at 300rpm for 1h, and stir evenly;

[0044] (3) Place the three-necked flask in a heating mantle and keep the temperature inside the flask at about 30°C;

[0045] (4) Slowly add 40g 15% bis(2-ethylhexyl) peroxydicarbonate solution in the there-necked flask, the rate of addition is 4 drops / second;

[0046] (5) Continue to maintain the temperature and stir for 20 hours to prepare a composite conductive adhesive of polyaniline / polyvinyl alcohol.

Embodiment 2

[0048] (1): Add 10g of bromoacetyl-substituted pyrrole tetramer and 300ml of 7M camphorsulfonic acid into a three-necked flask, ultrasonically for 20min, and mix well;

[0049] (2): Weigh 40g of 30wt% sodium carboxymethylcellulose aqueous solution, add it into a three-necked flask, stir at 300rpm for 1h, and stir evenly;

[0050] (3): Place the three-necked flask in a heating mantle and keep the temperature inside the flask at about 30°C;

[0051] (4): 30g of 11.11% potassium dichromate solution was slowly added to the three-necked flask, and the dropping rate was 4 drops / second;

[0052] (5): Continue to maintain the temperature and stir for 20 hours to prepare a composite conductive adhesive of polypyrrole / sodium carboxymethyl cellulose.

Embodiment 3

[0054] (1): Add 10g of bromoacetyl-substituted thiophene tetramer and 300ml of 7M dodecyl sulfonic acid into a three-necked flask, sonicate for 20min, and mix well;

[0055] (2): Weigh 40g of 30wt% polyacrylic acid aqueous solution, add it into a three-necked flask, stir at 300rpm for 1h, and stir evenly;

[0056] (3): Place the three-necked flask in a heating mantle and keep the temperature inside the flask at about 30°C;

[0057] (4): 30g of 11.11% potassium dichromate solution was slowly added to the three-necked flask, and the dropping rate was 4 drops / second;

[0058] (5): Continue to maintain the temperature and stir for 20 hours to prepare a composite conductive adhesive of polythiophene / polyacrylic acid.

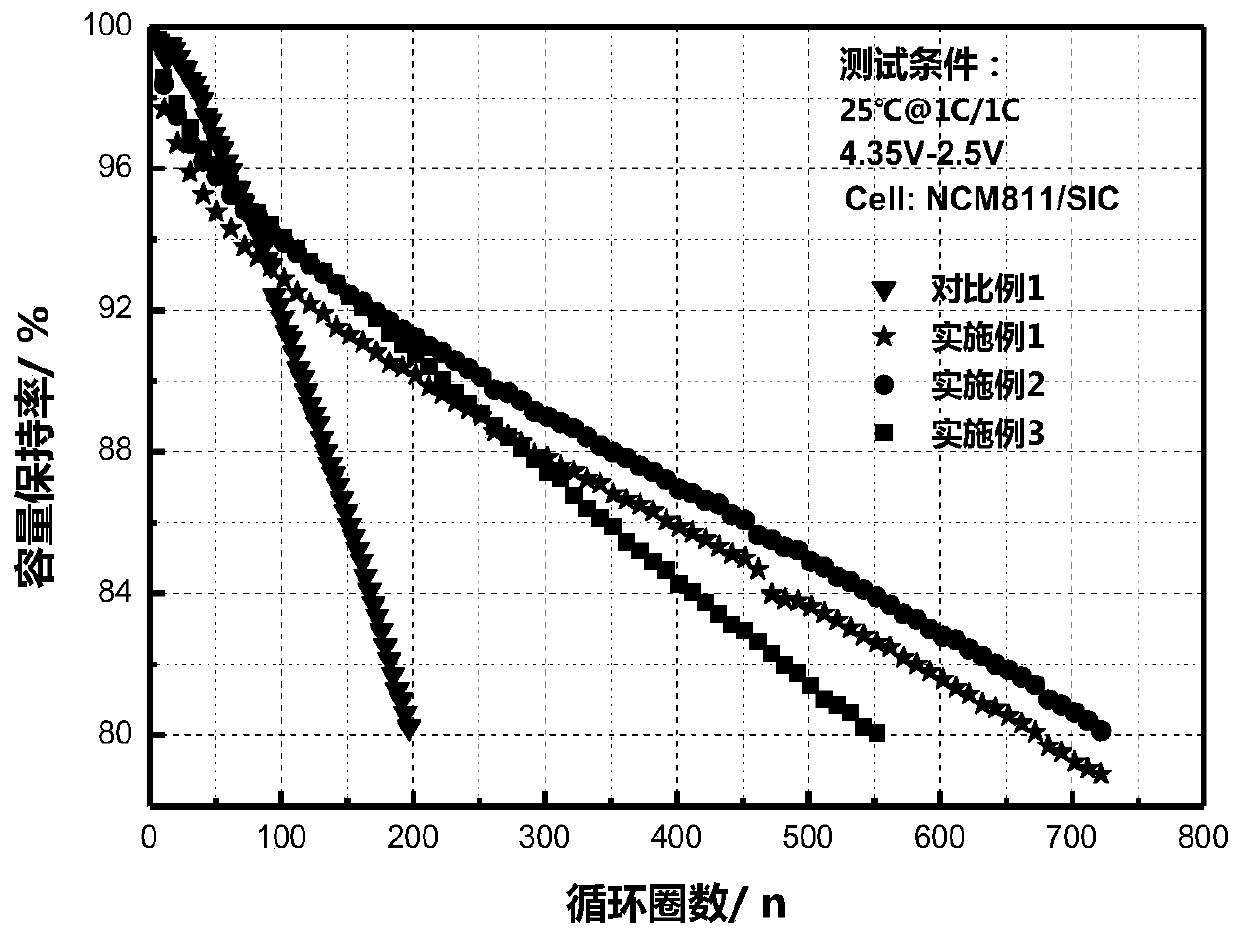

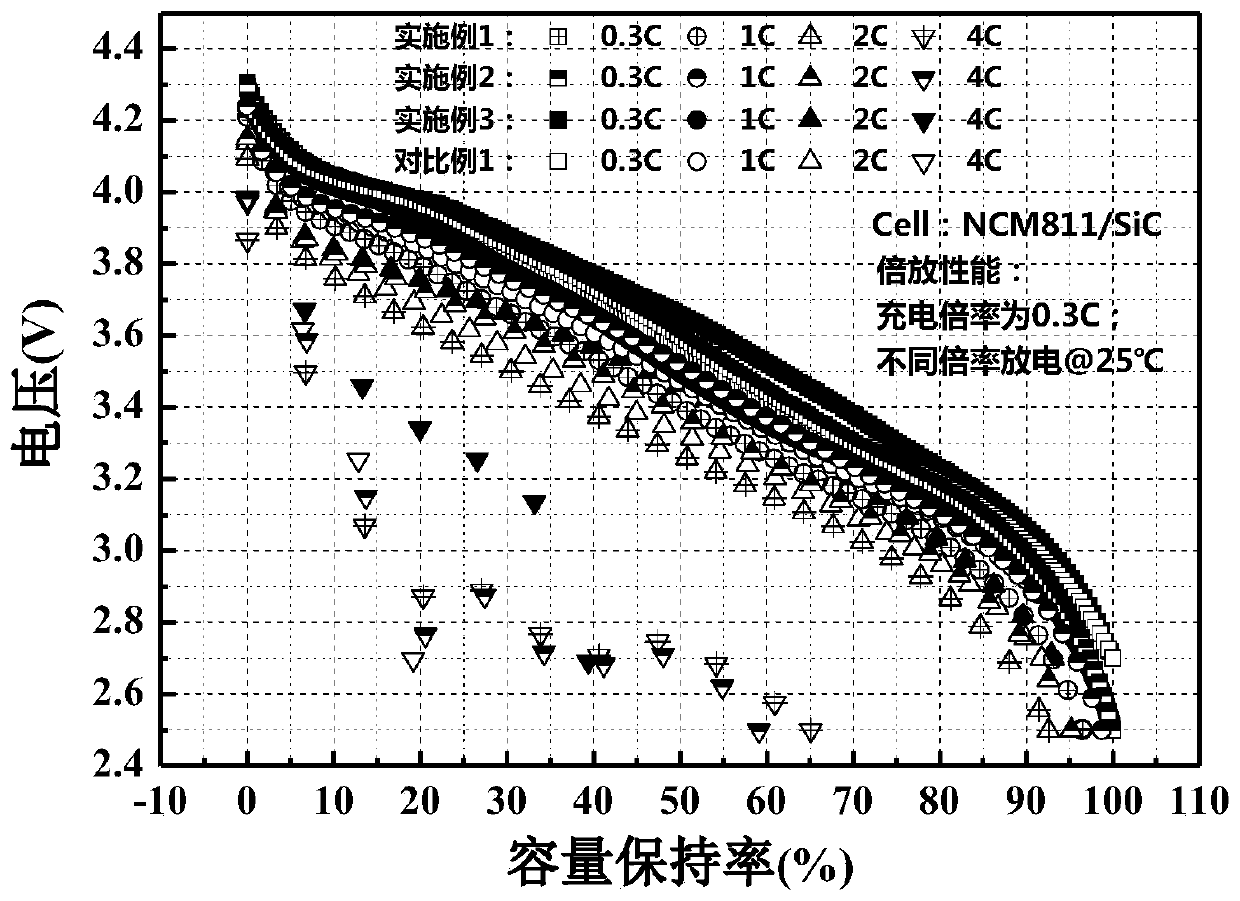

[0059] Prepare the composite conductive binder prepared in the above three embodiments and the silicon carbon active material in a ratio of 6:94 to prepare a uniformly mixed slurry, and coat the uniformly mixed negative electrode slurry on the copper foil, And vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com